Method for producing a prosthesis base

A prosthesis and base technology, used in dental prosthesis, medical science, dentistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

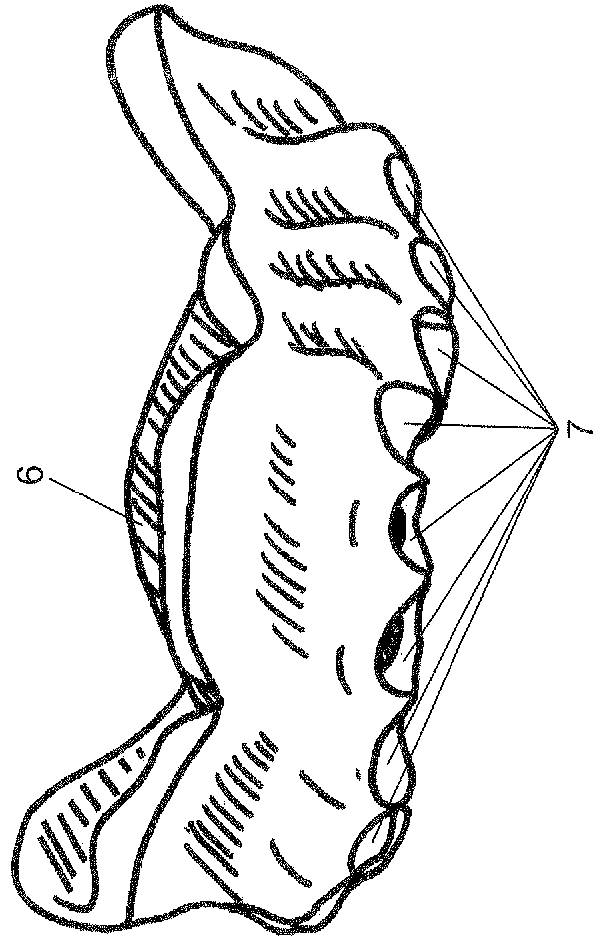

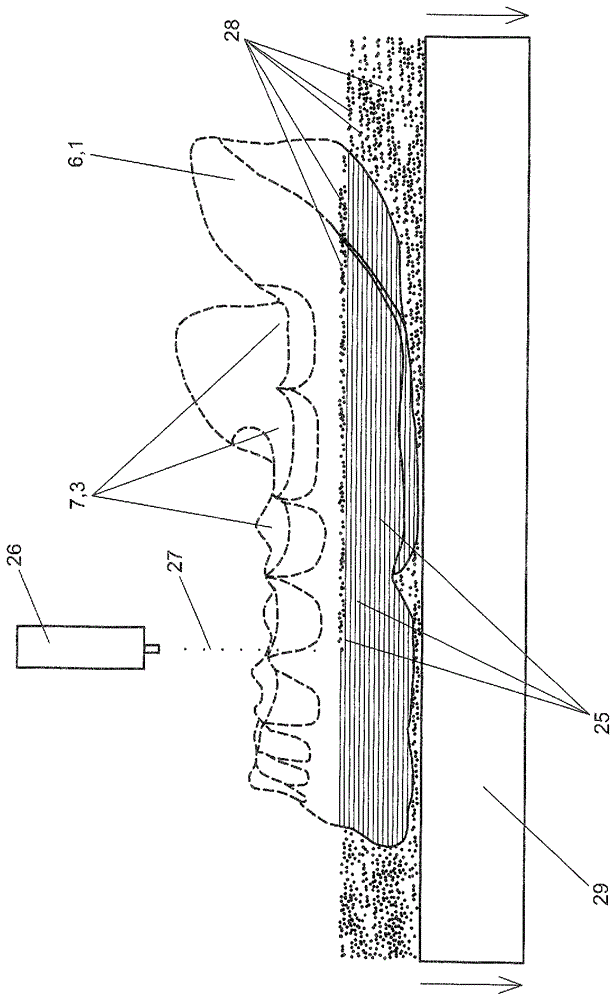

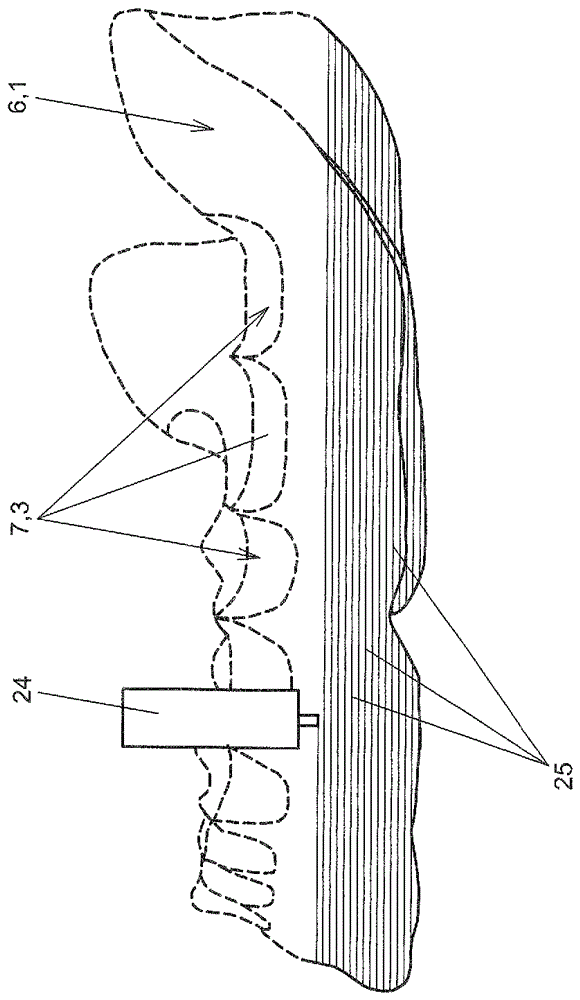

[0027] figure 1 A milling device 5 is shown in the form of a CNC milling device known in the prior art, which is triggered by a control computer 14 . The milling device 5 has a housing 12 with a machining cavity 15 . This processing cavity 15 is as when gate 13 is opened figure 1 It is shown that it is accessible from the outside and can be closed during the milling process by correspondingly lowering the gate 13 . A milling process for producing the temporary wax part 6 with the temporary wax part receiving recess 7 for the artificial tooth 4 can be carried out in the machining cavity 15 . To this end, a numerical data set is loaded into the control computer 14, which reflects the shape of the prosthetic base 1 to be produced with the prosthetic base receiving groove 3, which control computer will be used to produce the temporary wax Corresponding control commands for the milling process of the workpiece 6 are transmitted to the milling device 15 . For the milling pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com