Manufacturing method of pendant body engraved with personalized portrait relief

A manufacturing method and portrait technology, applied in image data processing, technology for producing decorative surface effects, instruments, etc., can solve problems such as low production efficiency, difficulty in obtaining models, and difficulty in engraving personalized portraits, and achieve rapid construction mode, sharpening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

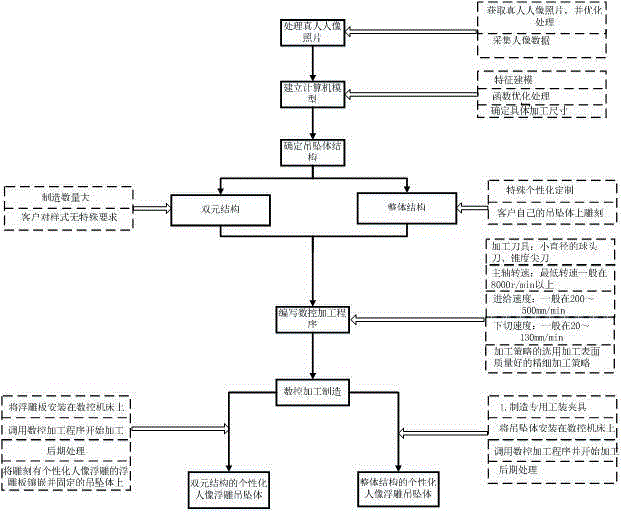

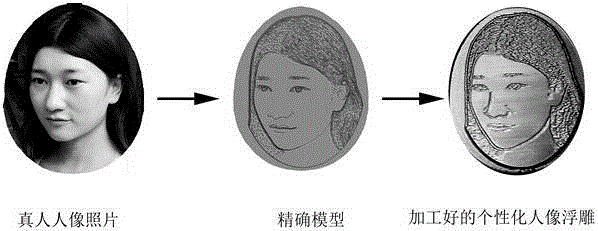

[0067] Example 1: see Figure 1 to Figure 3 , a method for manufacturing a pendant body carved with personalized portrait relief, comprising the steps of:

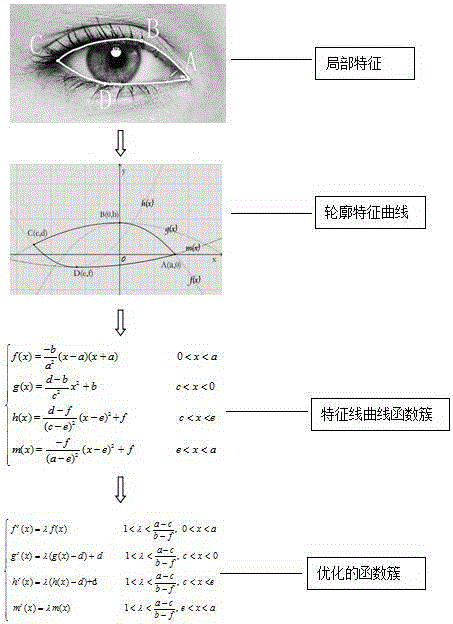

[0068] S11: A modeling method for a 2.2-dimensional relief model of a pendant body portrait based on real photos, including the following steps:

[0069] In view of the relatively small feature of the pendant body, in order to improve the similarity and realize the numerical control machining, the modeling scheme of the 2.2-dimensional relief model is adopted. 2. The specific structure of the 2-dimensional relief model is: for a 3D portrait model, set the maximum dimensions in the x, y, and z directions to be a, b, and c respectively; then when modeling, x

[0070] S11a: Obtain a photo of a real person, and optimize the photo of a real person;

[0071] Specifically, optimizing the photo of a real person mainly includes the following steps:

[0072] 1) Remove the photo noise and delete the background la...

Embodiment 2

[0105] Example 2: see Figure 1 to Figure 3 , a method for manufacturing a pendant body carved with personalized portrait relief, comprising the steps of:

[0106] S41: A modeling method for a 2.2-dimensional relief model of a pendant body portrait based on a real photo, comprising the following steps:

[0107] In view of the relatively small feature of the pendant body, in order to improve the similarity and realize the numerical control machining, the modeling scheme of the 2.2-dimensional relief model is adopted. 2. The specific structure of the 2-dimensional relief model is: for a 3D portrait model, set the maximum dimensions in the x, y, and z directions to be a, b, and c respectively; then when modeling, x

[0108] S41a: Obtain a photo of a real person, and optimize the photo of a real person;

[0109] Concretely: the optimization processing of the portrait photo of a real person mainly includes the following steps:

[0110] 1) Remove the photo noise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com