Fire extinguisher nozzle structure

A fire extinguisher and nozzle technology, which is applied in the field of fire extinguisher nozzle structure, can solve the problems of prolonging the spraying time of the fire extinguisher, and the fire extinguishing range of the fire extinguisher cannot be sprayed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

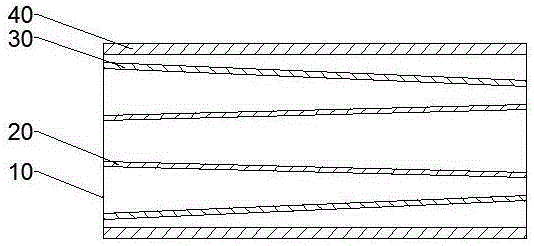

[0019] Such as figure 1 As shown, the structure of the fire extinguisher nozzle is as follows: including the nozzle and the pipe body 10 arranged inside the nozzle. The pipe body 10 is provided with three layers of pipe walls, and the adjacent pipe walls are connected by guide pieces along the axial direction of the pipe body. The aperture of the innermost pipe wall 20 of the pipe body 10 becomes smaller from the fire extinguishing agent inlet end to the outlet end, and the aperture diameter of the second layer pipe wall 30 of the pipe body 10 becomes larger from the fire extinguishing agent inlet end to the outlet end.

[0020] In addition, in this embodiment, the guide fins are uniformly arranged along the circumferential direction of the tube body 10 . The advantage is that the fire extinguishing agent sprayed by the fire extinguisher is evenly sprayed in the circumferential direction. There are at least two guide pieces between adjacent pipe walls. The advantage is that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com