Injecting device

A technology of spraying device and spraying head, applied in spraying device, spraying device, liquid spraying device, etc., can solve the problems of low spraying pressure and residual medium, and achieve the effect of increasing spraying distance, high pressure and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

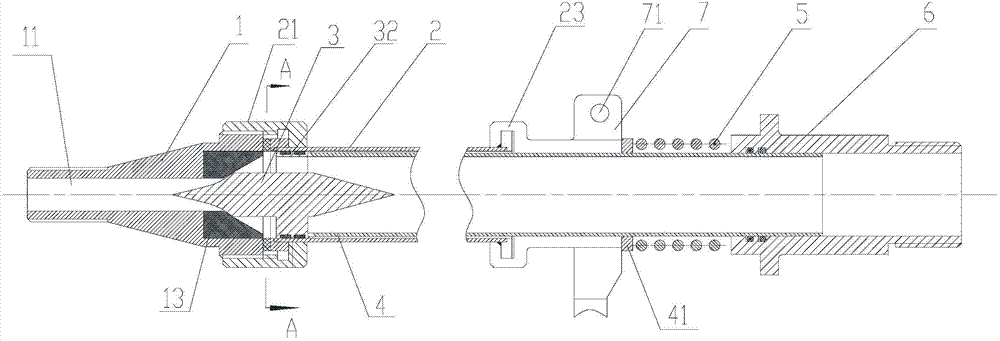

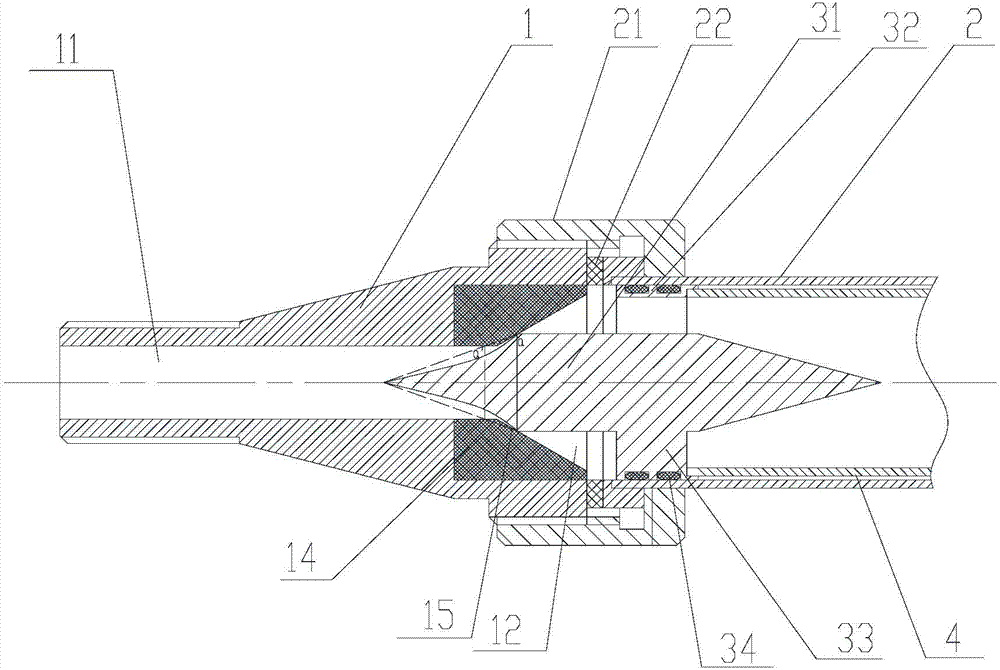

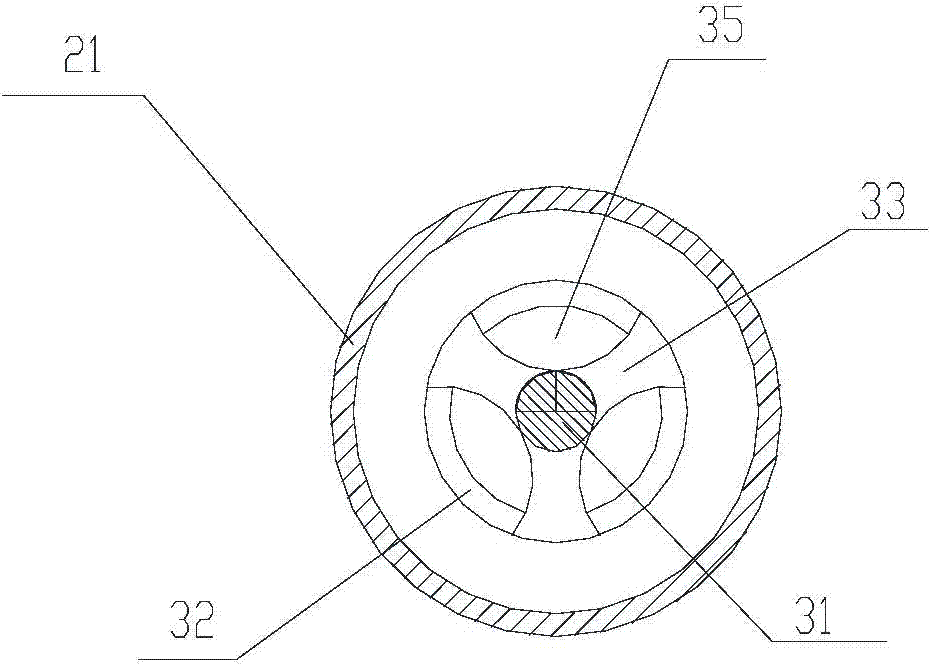

[0033] figure 1 It is a structural schematic diagram of a spraying device according to an embodiment of the present invention, figure 2 for figure 1 A partially enlarged schematic diagram of the injection device in . like figure 1 and figure 2 As shown, the spraying device of the present invention includes a spray head 1 , a spray pipe 2 , a valve core 3 and an elastic member 5 . Wherein, the spray head 1 has a spray head chamber 12 and a nozzle 11 communicating with the spray head chamber 12 , and the inner wall of the spray head chamber is provided with a valve seat 13 . In this embodiment, the valve seat 13 is arranged at the position where the nozzle cavity and the nozzle 11 meet, so that the matching position of the valve core 3 and the valve seat 13 is also at the position where the nozzle cavity and the nozzle 11 meet, When the valve core 3 is disengaged from the valve seat 13, the liquid passes through the valve seat 13 and directly enters the spout 11 to be spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com