Full-automatic device achieving quality detecting and weight grading for food processing process line

A food processing and assembly line technology, applied in the direction of sorting, etc., can solve the problems of low processing efficiency, waste of manpower, high labor intensity, etc., and achieve the effect of achieving a high degree of mechanical intelligence, saving labor costs, and eliminating cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better illustrate the present invention, the specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be pointed out again that this specific embodiment is only used as a preferred embodiment of the present invention, and is not a limitation of the protection scope of the present invention. .

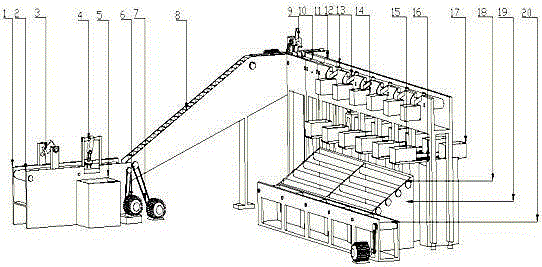

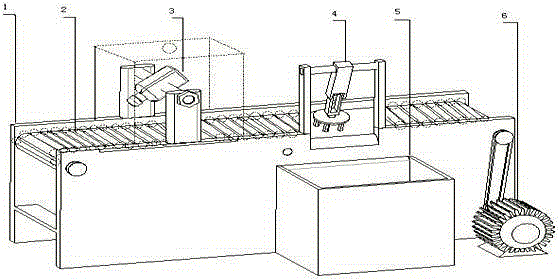

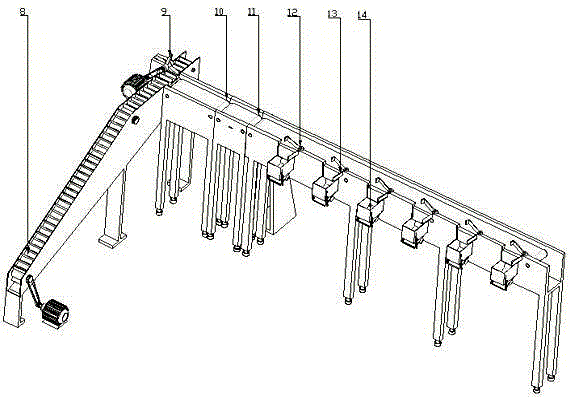

[0024] according to Figure 1-7 As shown, the present invention relates to a fully automatic equipment for quality detection and weight classification of a food processing line, comprising a frame 1, a roller conveyor belt 1, a format conveyor belt 8, a transition conveyor belt 10, a weighing conveyor belt 11 and a food conveyor belt Belt 20, the frame 1 is provided with a roller conveyor belt 2, the roller conveyor belt 2 is provided with a camera 3, one side of the roller conveyor belt 2 is connected to a format conveyor belt 8, and the roller conveyor belt 2 is connected to a format conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com