Radiation prevention three-dimensional paper cut and manufacturing method thereof

A radiation-proof, three-dimensional technology, applied in special patterns, special decorative structures, decorative arts, etc., can solve problems such as unresolved chips or films, and achieve the effect of improving the layered three-dimensional effect and the best three-dimensional expression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

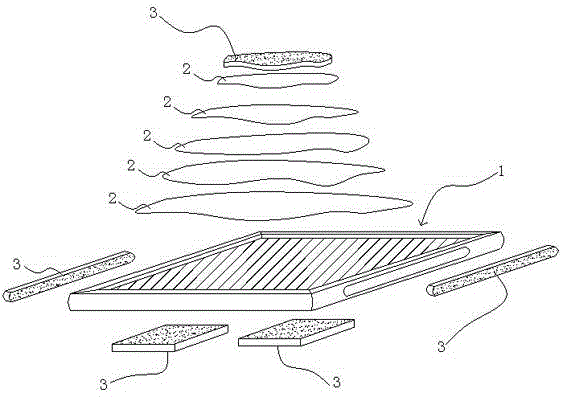

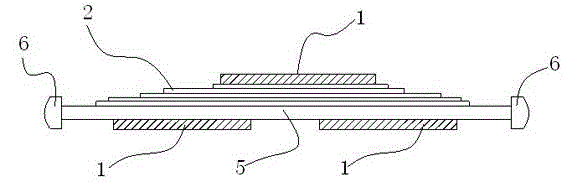

[0031] according to figure 1 and figure 2 As shown, the anti-radiation three-dimensional paper-cut in this embodiment is mainly composed of the substrate 1 and the paper-cut layer pasted on the surface of the substrate 1 .

[0032] The paper-cut layer is mainly composed of a group of paper-cut sheets 2 that are gradually reduced in size and bonded layer by layer. Of course, for design needs, the paper-cut layer can also be composed of only one layer of paper-cut sheets.

[0033] Also include electromagnetic wave absorbing sheet 3, electromagnetic wave absorbing sheet 3 is pasted on the surface of paper-cut layer, the thickness of electromagnetic wave absorbing sheet 3 is 2mm, also can select the electromagnetic wave absorbing sheet 3 of 0.1mm-10mm thickness for different designs.

[0034] The substrate 1 is composed of a bottom plate and frame strips that continuously surround the edges of the bottom plate. The back of the bottom plate and the surface of the frame strips can...

Embodiment 2

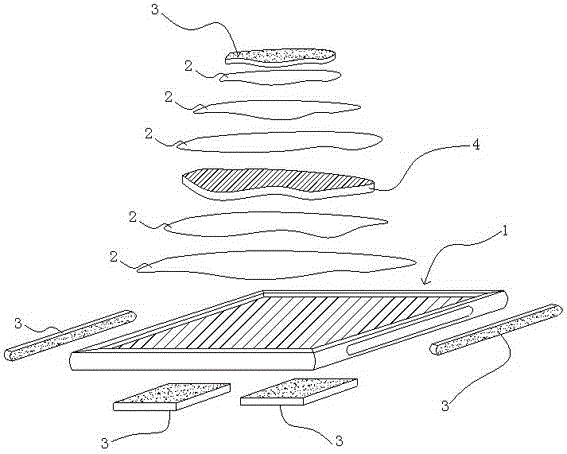

[0045] In order to further increase the anti-radiation absorbing ability and improve the three-dimensional display effect, such as image 3 As shown, in step d, the electromagnetic wave absorbing sheet 3 is also embedded in the paper-cut layer as a gasket 4, and the front and back sides of the gasket 4 used for bonding are roughened. The paper-cut sheets 2 above and below the pad 4 are partially pasted on the pad 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com