Caster with braking device

A technology for brakes and casters, which is applied to casters, wheels, motor vehicles, etc., can solve the problems of heavy weight, complicated brake release operations, and increased costs, and achieve the effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

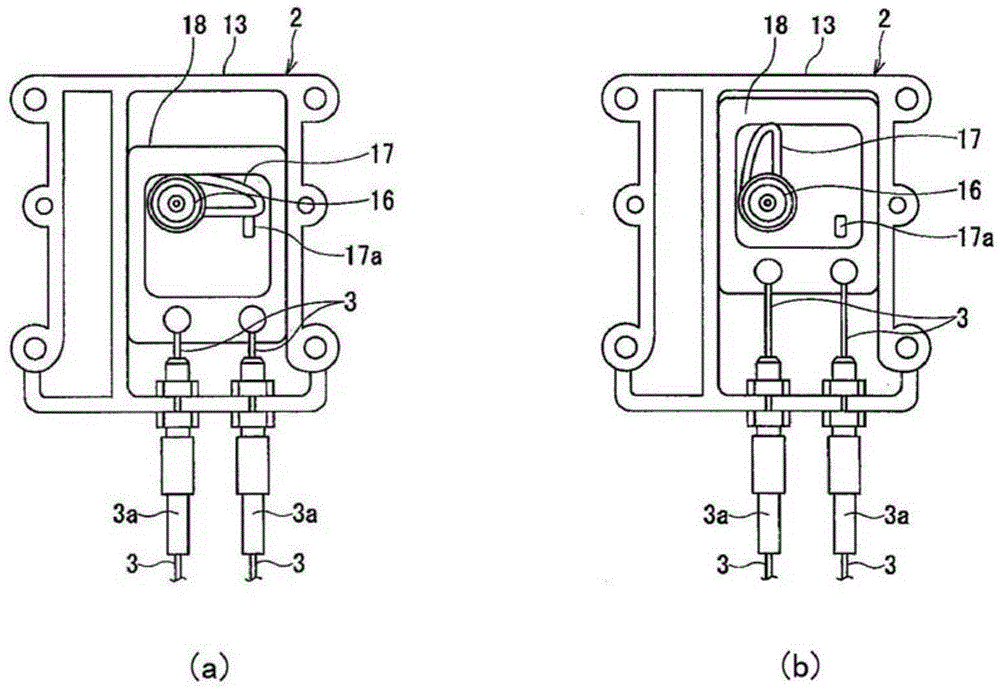

[0027] Embodiments of the present invention will be described below with reference to the accompanying drawings. In addition, the same code|symbol is attached|subjected to the same or equivalent part in several drawings.

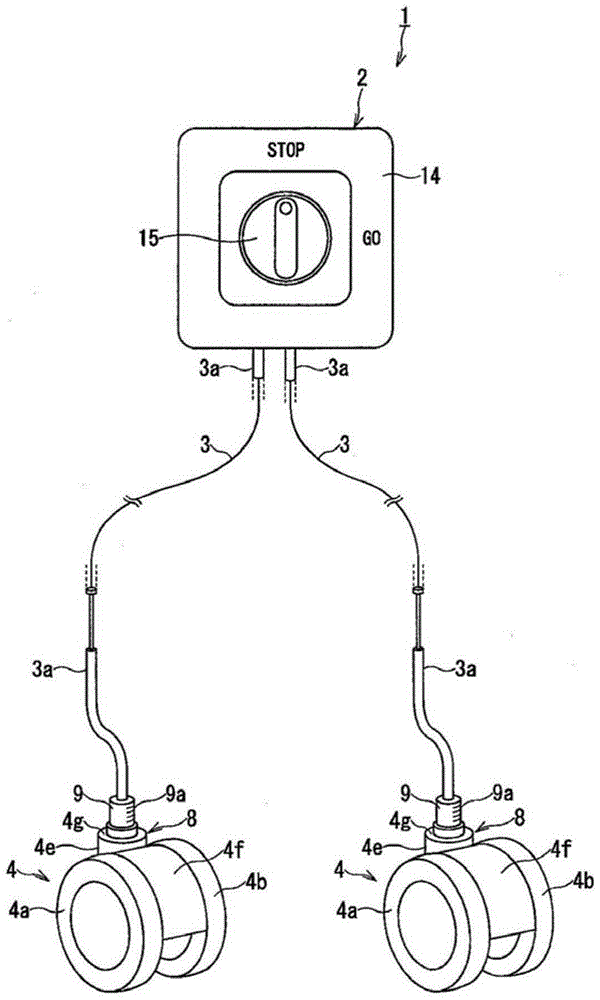

[0028] figure 1 It is a perspective view which shows the whole structure of the caster with brake 1 which concerns on this embodiment, and partially abbreviates. as it should figure 1 As shown, on the operation unit 2 of the caster 1 with brakes, there are multiple flexible metals, such as two transmission wires 3, 3, and multiple, such as two first casters made of synthetic resin. 4, 4.

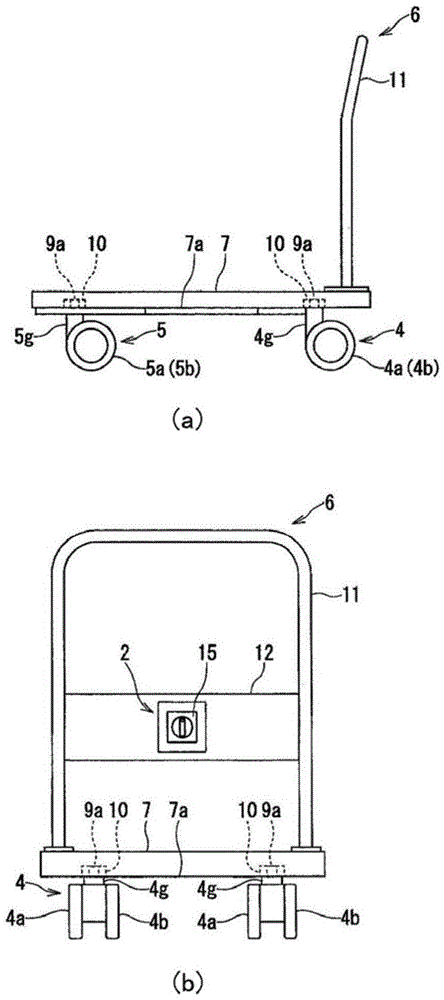

[0029] like figure 2 As shown in (a) and (b), these two first casters 4, 4 are respectively arranged on metal, etc. On the outer bottom surface of each corner of the bottom 7 of the trolley 6.

[0030] That is, the bottom 7 of the trolley 6 is formed into a shape such as a flat bottom corner by sheet metal, etc., and a pair of left and right second casters 5, 5 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com