Cooling passages for inner casing of a turbine exhaust

一种内部壳体、涡轮机的技术,应用在机械设备、发动机元件、机器/发动机等方向,能够解决无法充分且均匀地冷却、支柱热收缩和热膨胀差异、热应力损坏等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

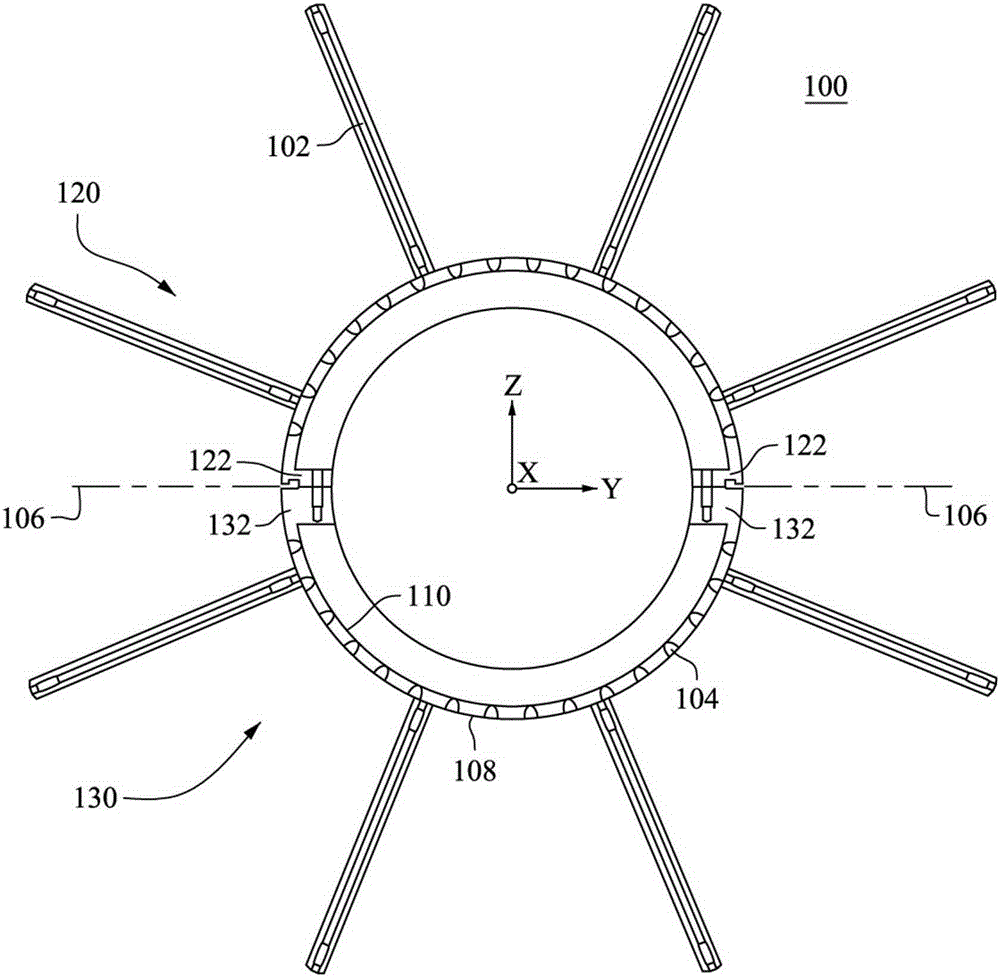

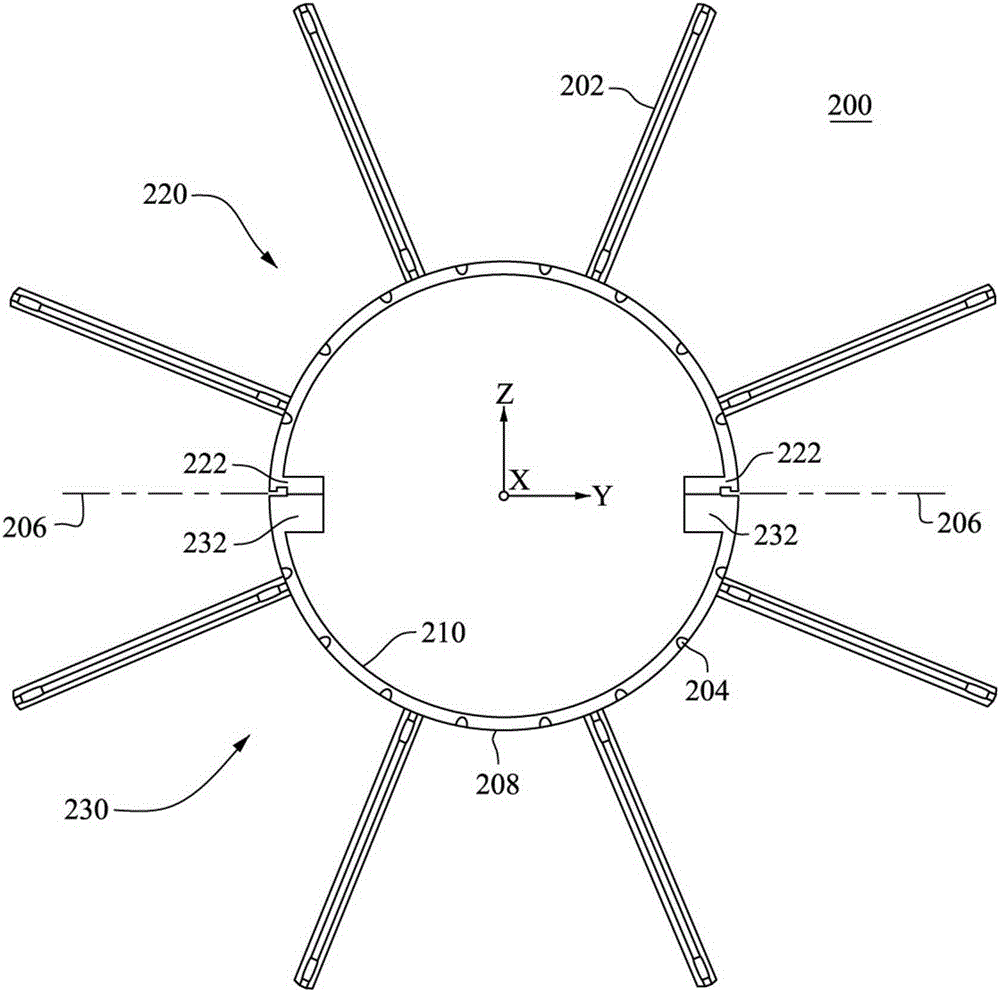

[0018] figure 1 A conventional inner housing 100 is shown with cooling passages along the inner housing. The inner housing 100 includes semi-cylindrical housing covers, namely an upper inner housing cover 120 and a lower inner housing cover 130 . The housing shells are joined at the parting line 106 (eg, the seam between the cylinder shells) by joining the two upper flanges 122 with the two lower flanges 132 at the parting line 106 .

[0019] The struts 102 are located on the outer circumference 108 of the upper inner housing shell 120 and the lower inner housing shell 130 of the inner housing 100 . The struts 102 on the upper inner housing shell 120 and the lower inner housing shell 130 are symmetrical, and the struts 102 are generally equally spaced from each other.

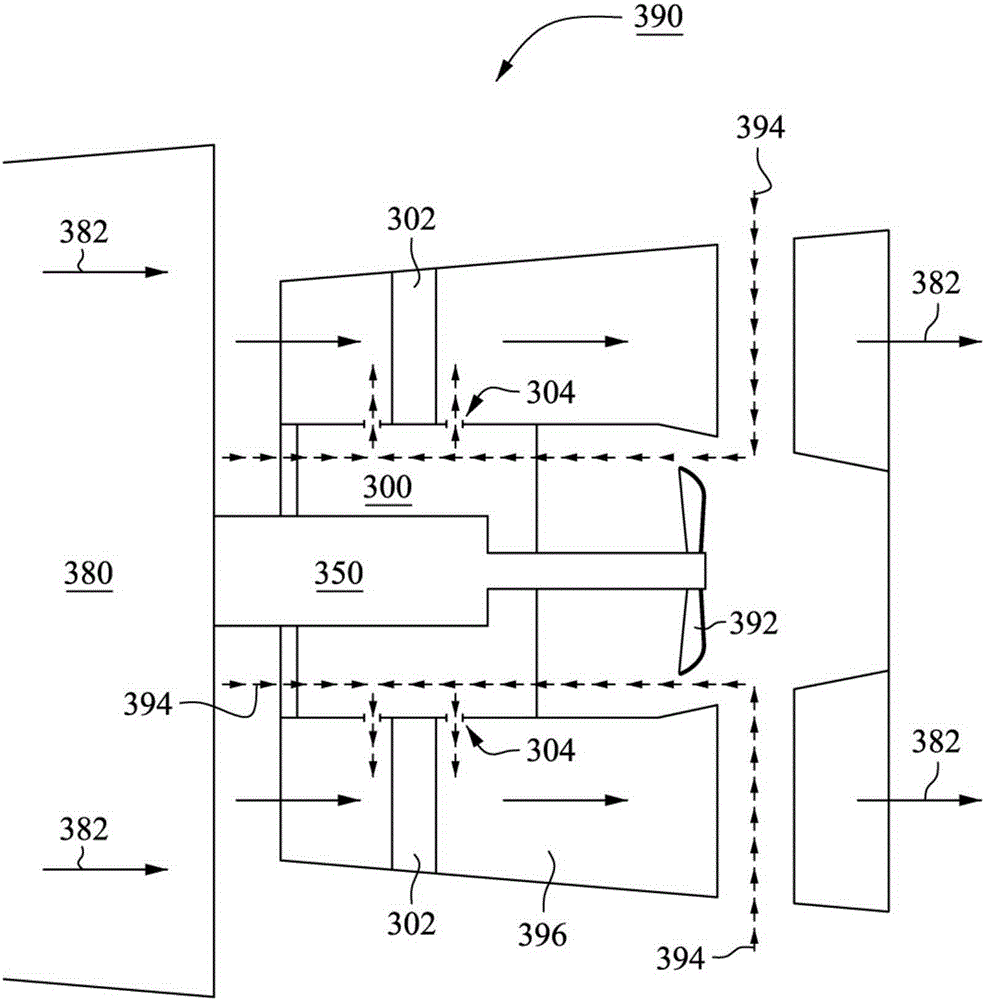

[0020] As used in conventional gas turbine exhaust sections, the inner casing is positioned such that the heated exhaust flow from the gas turbine exits the exhaust section by flowing through struts on the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com