Both-way damping adjustable shock absorber

A two-way damping and shock absorber technology, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problem of inability to adapt to different road conditions, poor shock absorption effect, and unadjustable shock absorption strength of shock absorbers And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

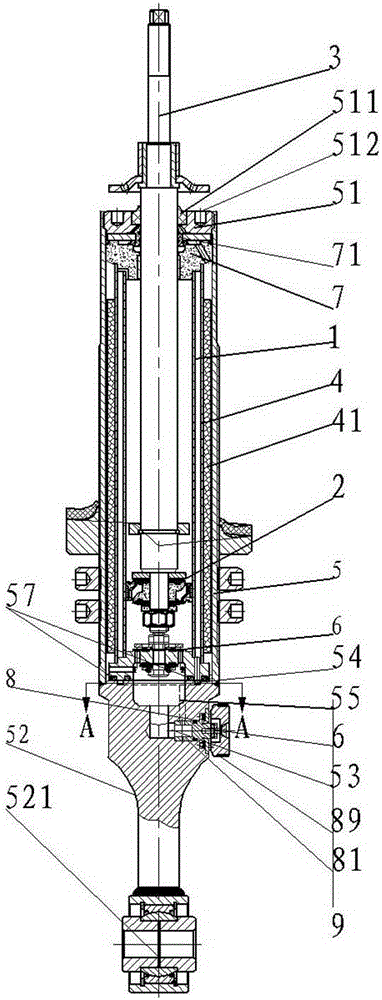

[0014] Such as figure 1 , Figure 4 As shown, the two-way damping adjustable shock absorber includes a working cylinder 1, a piston 2 disposed in the working cylinder 1, a piston rod 3 whose inner end is connected to the piston 2, an oil return pipe 4 sleeved outside the working cylinder 1, and a sleeve The oil storage cylinder 5 arranged outside the oil return pipe 4, the bottom of the working cylinder 1 and the oil return pipe 4 is provided with a bottom valve 6, the upper end of the working cylinder 1 and the oil return pipe 4 is provided with a guide 7, and the oil storage The upper end of the barrel 5 is provided with a fastening cover 51, and the lower end of the oil storage barrel 5 is provided with a bottom cover 52, which is characterized in that a mechanically adjustable knob 8 is provided on one side of the bottom cover 52, and a Adjustment hole 53, the mechanically adjustable knob 8 is installed in the adjustment hole 53, the joint end of the bottom cover 52 and t...

Embodiment 2

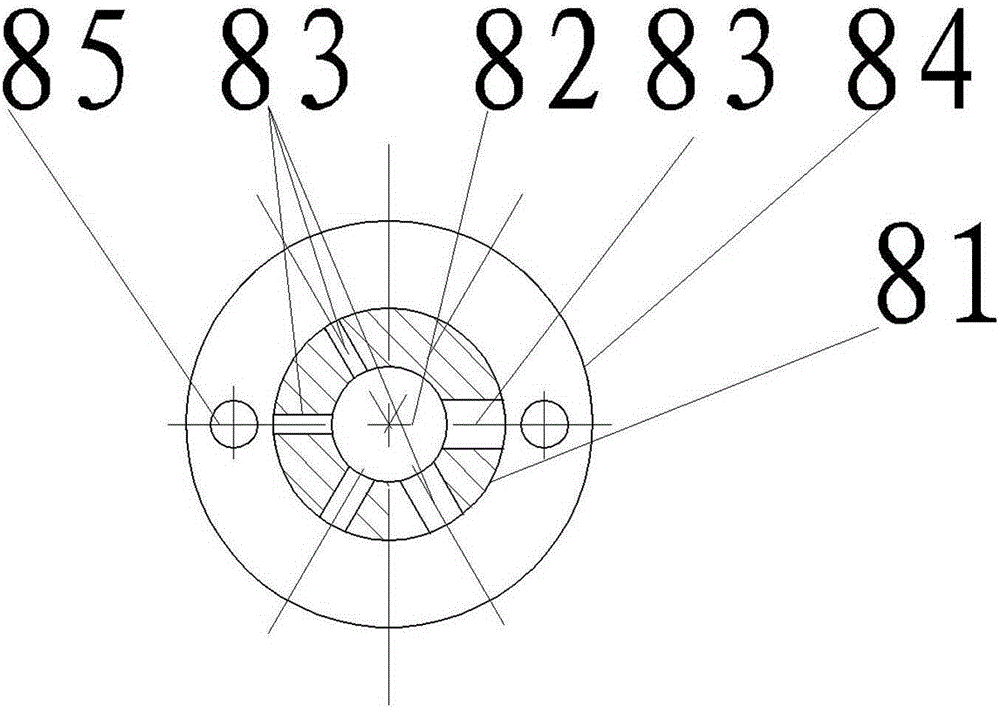

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the mechanically adjustable knob 8 includes an adjustment column 81 installed in the adjustment hole 53. The inner end of the adjustment column 81 is hollow and is an adjustment chamber 82. The side walls of the adjustment chamber 82 are provided with different diameters. A flow hole 83, the flow hole 83 corresponds to the adjustment hole 53, the adjustment column 81 is provided with a retaining ring 84, the retaining ring 84 is provided with a steel ball hole 85, the joint surface of the bottom cover 52 and the retaining ring 84 Steel ball slot 55 is provided on the top, steel ball 86 is installed in 88 of said steel ball hole 85, and butterfly spring 87 is arranged on the outside of said retaining ring 84, and said butterfly spring 87 acts on steel ball 86, and said butterfly spring The outside of 87 is provided with a T-shaped block 88, and the T-shaped block 88 is set on the outer end of the adjustment...

Embodiment 3

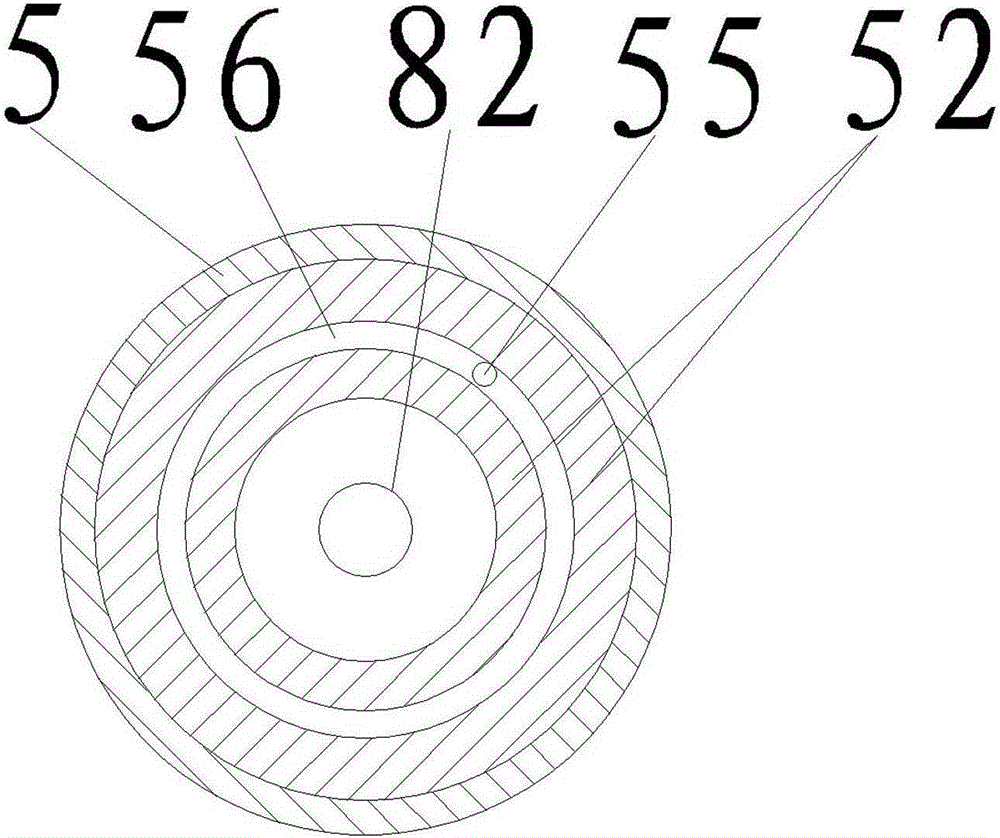

[0018] Such as figure 1 , figure 2 , Figure 4 As shown, the oil return pipe 4 is covered with a foam layer 41, the upper end of the guide 7 is provided with an oil seal 71, the bottom cover 52 is connected with a suspension ring 521, and the fastening cover 51 is connected to the inner wall of the upper end of the oil storage cylinder 4. For screw fit, the end face of the fastening cover 51 is provided with two clamping holes 511 for installing the fastening cover 51, and the middle part of the fastening cover 51 is provided with a sealing ring 512, and the sealing ring sleeve 512 is arranged on the piston rod 3 superior. When working, the hydraulic oil of the working cylinder 1 enters the oil return cavity between the oil return pipe 4 and the working cylinder 1, then enters the oil collection tank 56, and then flows through the connecting channel 55, the regulating hole 53, and the regulating chamber 82 of the regulating column 81. The bottom valve 6 returns to the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com