Energy-saving stove base

A technology of energy-saving stoves and fixed steps, which is applied to stoves/stove bases and other directions, can solve the problems of unstable quality and heavy weight of ordinary stoves, and achieve the effects of reducing total cost, convenient and quick ash removal, and weight reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

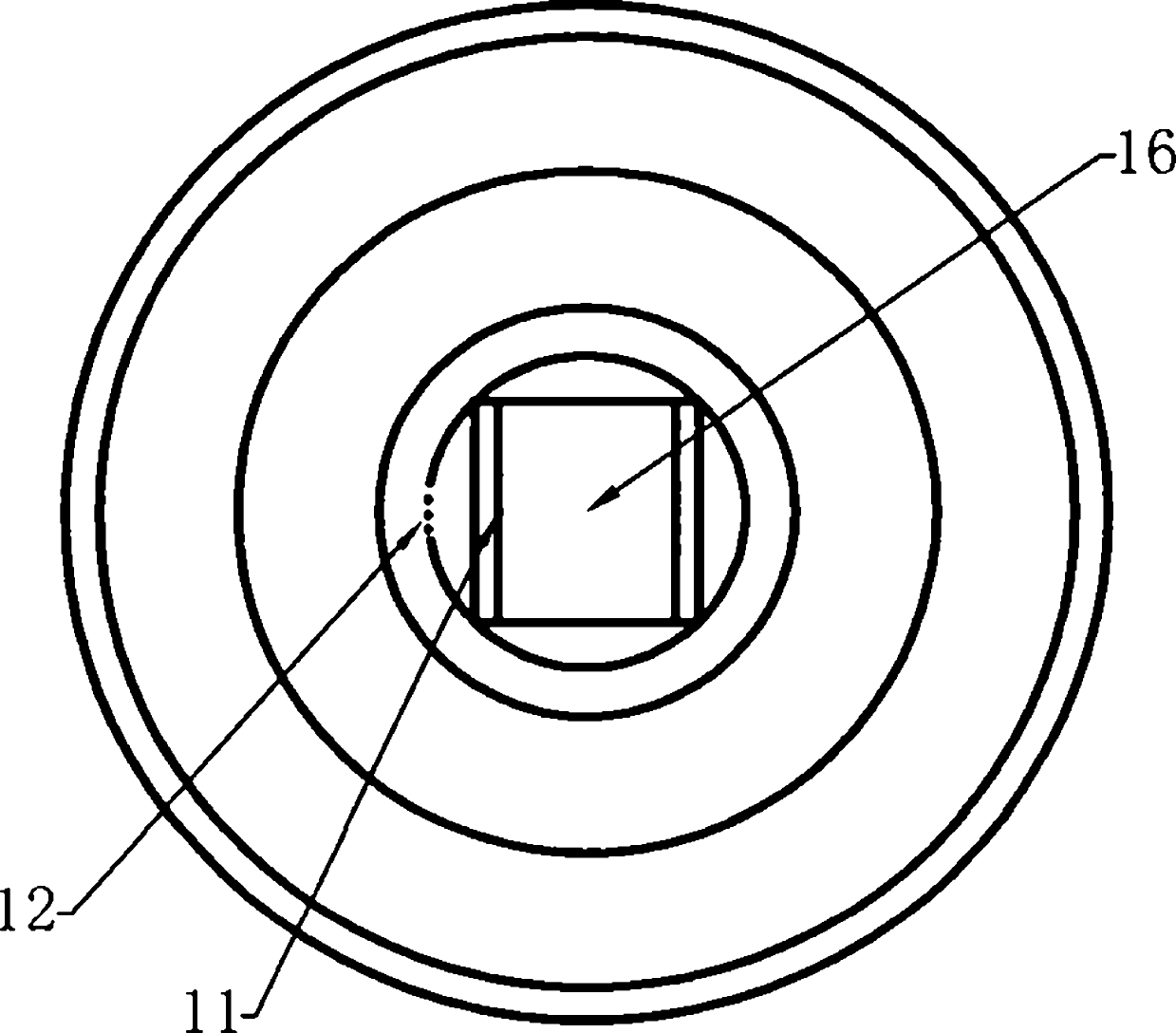

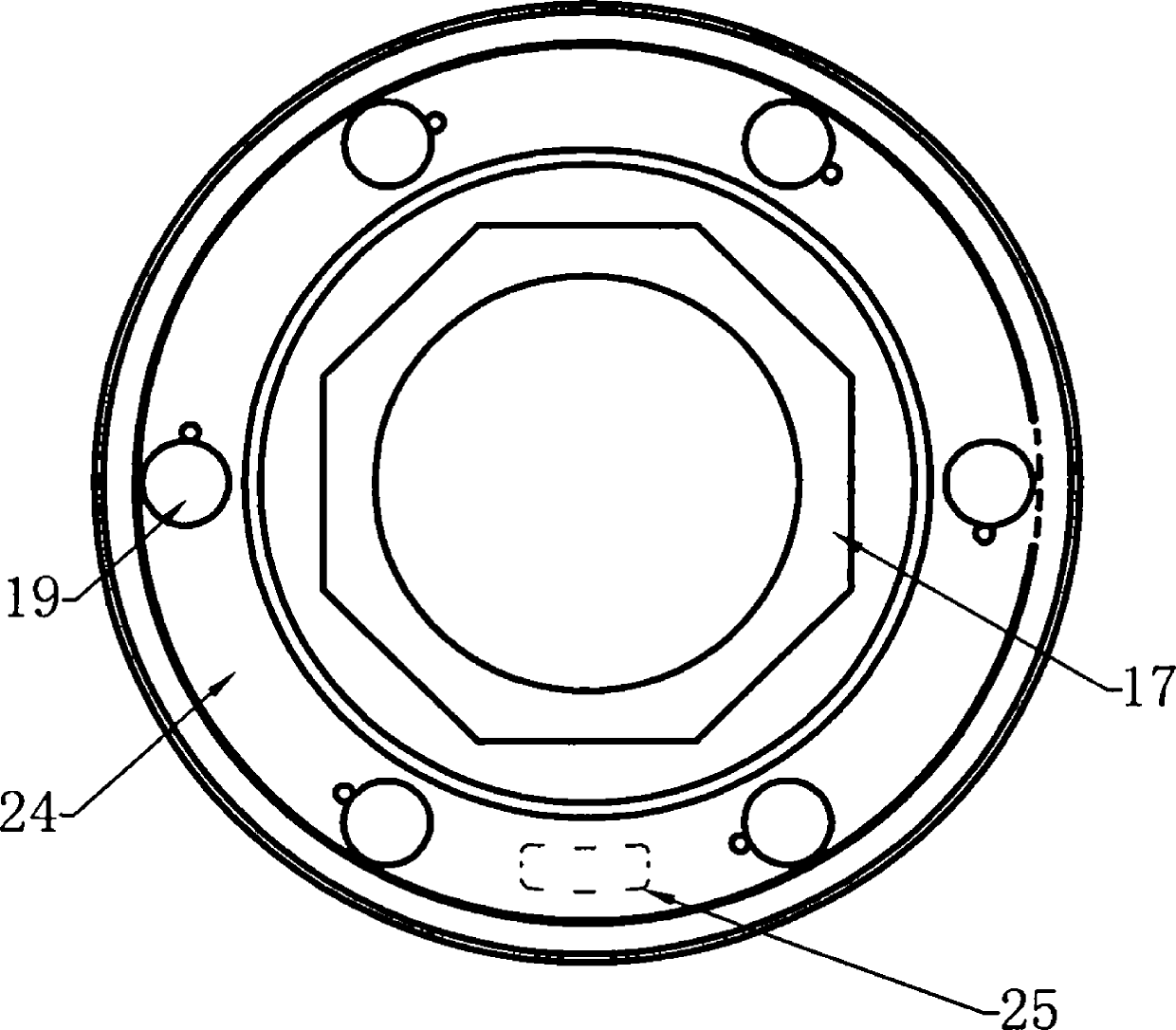

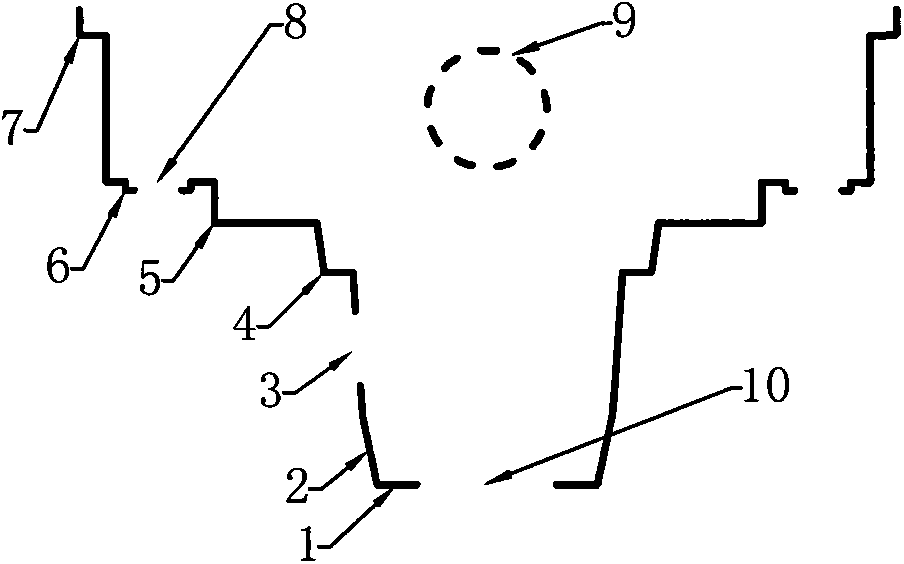

[0024] figure 1 , figure 2 A structural form of an energy-saving stove base is described. An energy-saving stove base, mainly composed of specific multi-level steps, the first fixed step of waste heat recovery device 7, the first fixed step of ash board 6, the first fixed step of refractory furnace core 5, the first fixed step of stove grate 4 , circle-quadrilateral transition section 2, the first slag plate fixed steps 1 are connected together to form the first energy-saving cooker base; the appearance of the first energy-saving cooker base is stepped cylindrical, or stepped prismatic, or stepped circular frustum , or stepped prism shape; the base of the first energy-saving stove has a first air inlet 3; the first row of ash board fixed steps 6 has a first row of ash holes 8; the upper part of the first energy-saving stove base has a first smoke outlet 9 There is a first slag hole 10 on the first slag plate fixed step 1; the first waste heat recovery device fixed step 7, t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap