Electric heating device

An electric heating device and electric heating tube technology, applied in the field of heaters, can solve problems such as inconvenient installation, waste of resources, and unfavorable air circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

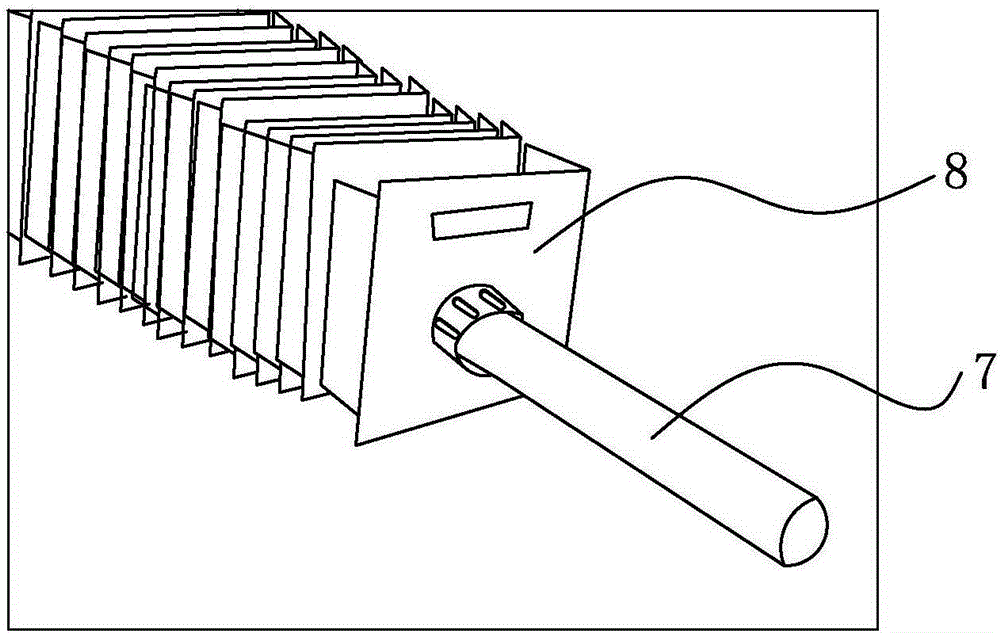

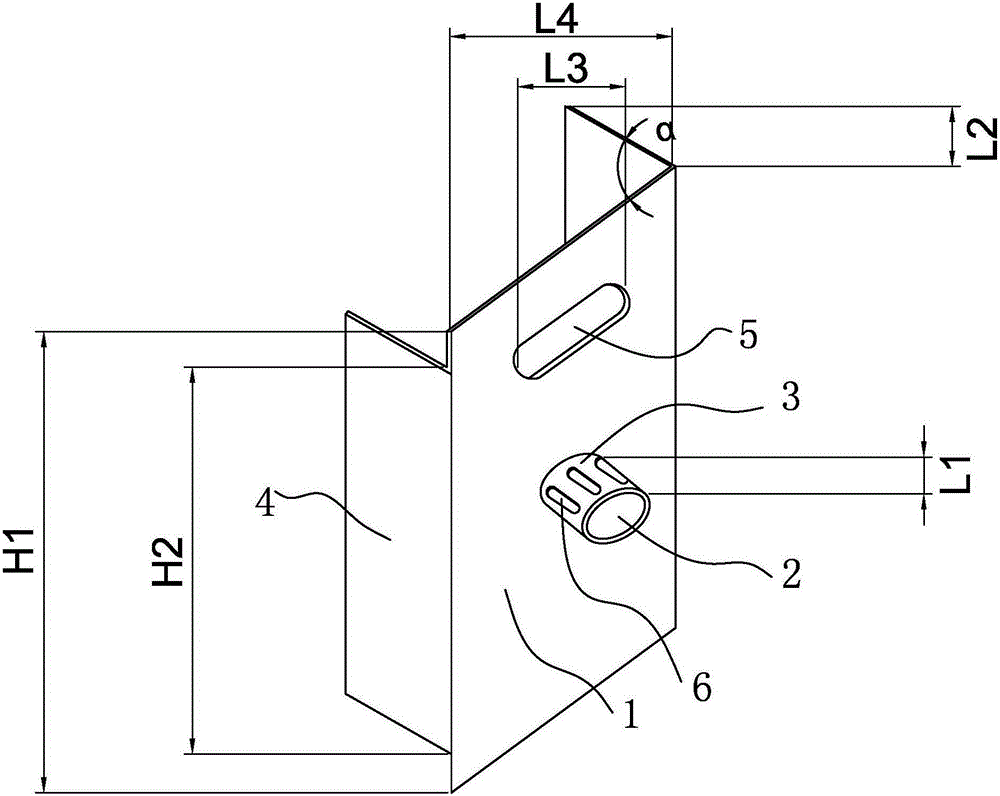

[0013] Such as Figure 1-2 As shown, the electric heating device includes an electric heating tube 7 and a heat sink 8. The heat sink 8 includes a main body 1 of a sheet metal structure, a through hole 2 is opened in the middle of the main body, a flange 3 is provided on the edge of the through hole, and flanges are also provided on both sides of the main body. 4. The direction of the flange 4 is opposite to that of the flange 3 . A plurality of cooling fins are sleeved and installed on the electric heating tube 7 through the through hole 7 to realize heating and heat dissipation. Combined with the length of the flange 3 and the length of the flange 4, the distance between the two heat sinks on the electric heating tube can be determined. Only when the diameter of the through hole and the flange is larger than the diameter of the electric heating tube installed by the cooling fin can it be socketed on the electric heating tube.

[0014] The turning angle α between the flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com