Hollow axle inner hole coaxiality detection device

A hollow axle and detection device technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of difficult measurement, difficult observation, and inconvenient measurement, so as to improve the processing technology level, shorten the detection period, Measuring the effect of convenience and quickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

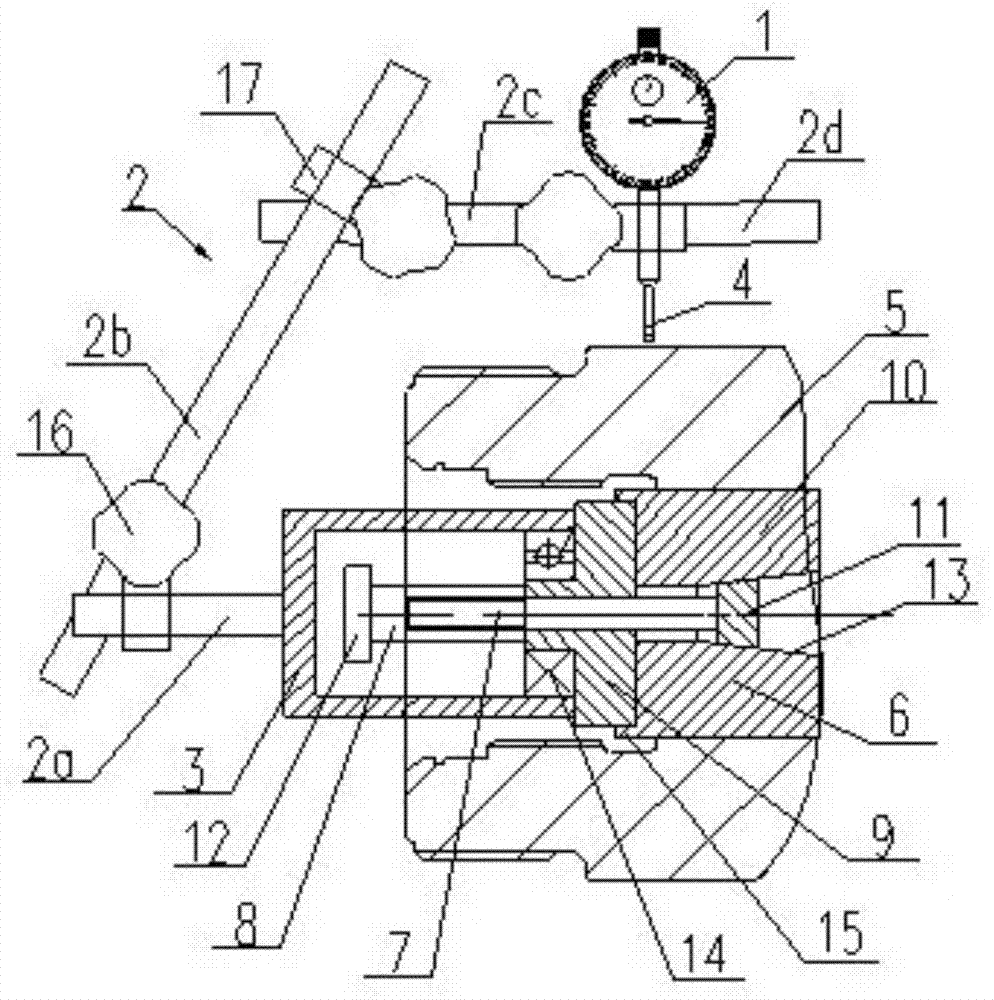

[0022] Such as figure 1 As shown, a hollow axle inner hole coaxiality detection device includes a measuring instrument, a slewing mechanism and a self-centering component. Among them, the commonly used dial indicator 1 is selected for the measuring instrument, and the self-centering component is inserted into the inner hole of the axle 5 and fixed. The slewing mechanism is composed of a lever mechanism 2 and a bracket 3. One end of the lever mechanism 2 is fixed on the bracket 3. The other end of the lever mechanism 2 is fixedly installed with a dial indicator 1, and the bracket 3 is rotatably connected with the self-centering assembly. The probe 4 of the dial indicator 1 rests on the outer circumferential surface of the axle 5. After installation, the slewing mechanism, self-centering The assembly is coaxial with the inner hole of the axle, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com