Gap Elimination Device for Guide Bush of Railway Freight Car Brake Beam Fatigue Test Bench

A fatigue test, railway wagon technology, applied in railway vehicle testing, etc., can solve the problems of test loading frequency drop, unreliability, constraints, etc., to achieve the effect of avoiding the drop of loading frequency, ensuring accuracy, and ensuring test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

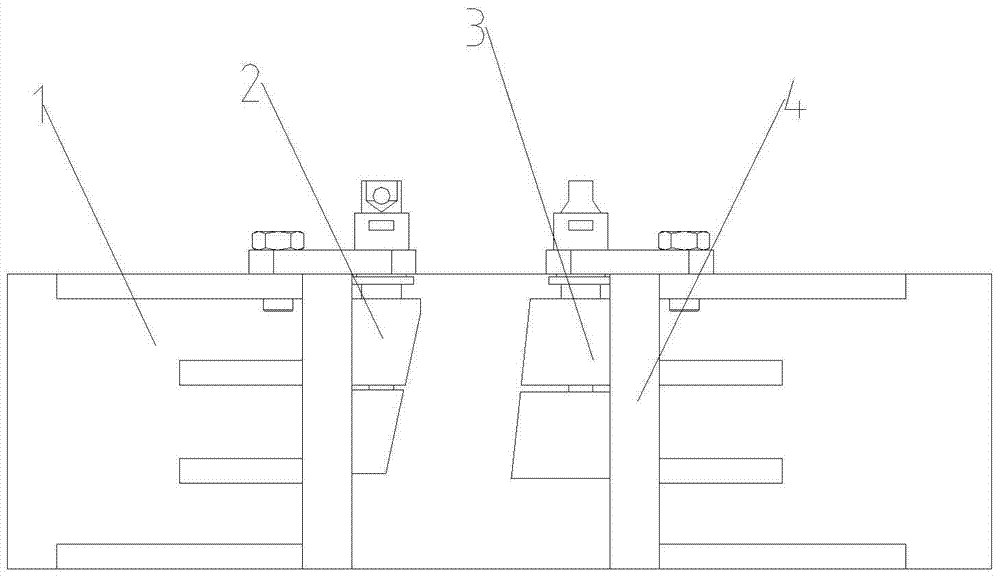

[0028] Such as figure 1 As shown, the guide sleeve gap elimination device of the railway wagon brake beam fatigue test bench includes the adjustment device I2 and the adjustment device II3 used in pairs. During the test, the two are respectively installed on the test bench 1, and the left and right sides of the brake beam guide sleeve sides.

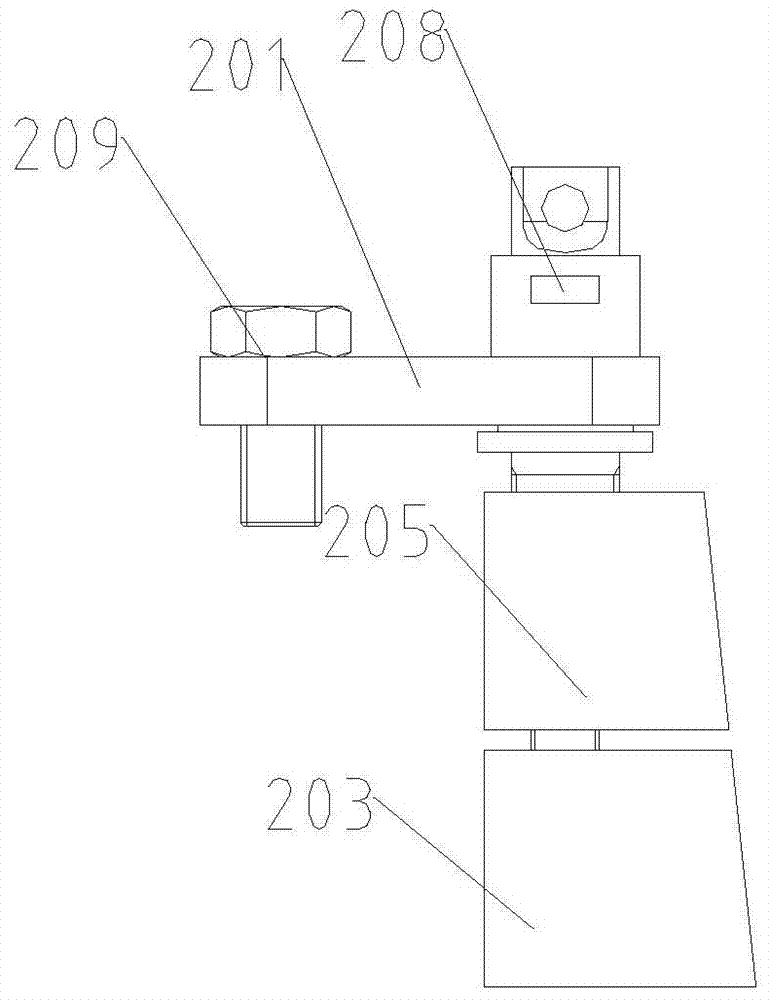

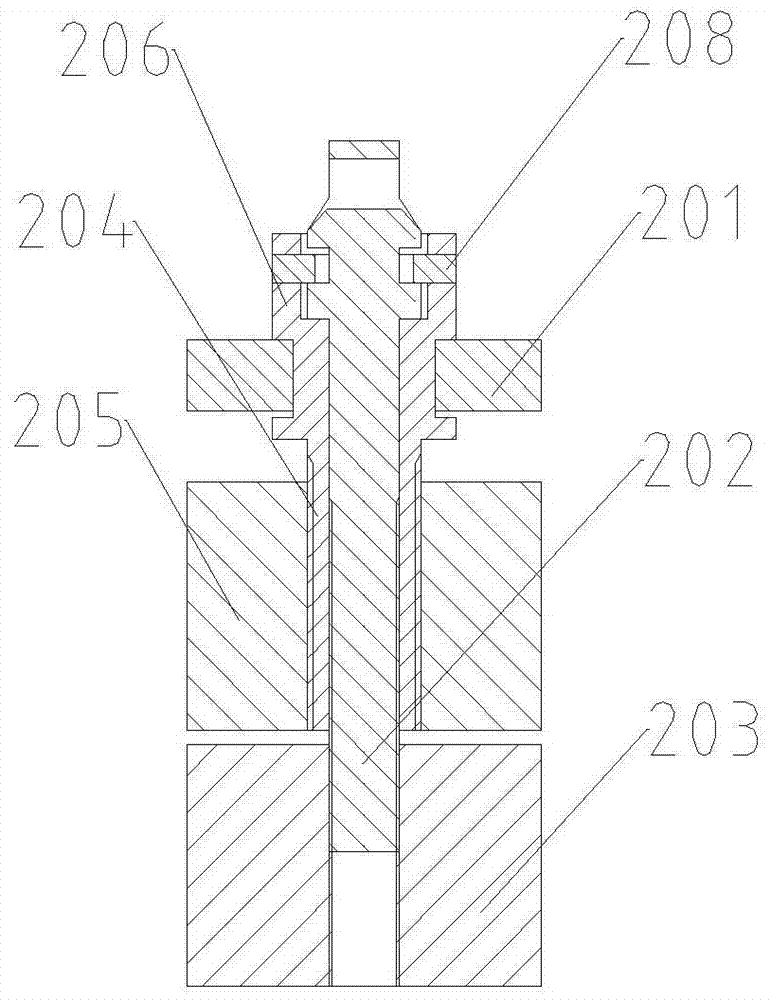

[0029] Such as figure 2 and image 3 As shown, the adjustment device I2 includes a pressure plate 201, an inner adjustment shaft 202 and a lower adjustment block 203; the lower adjustment block 203 is installed on the inner adjustment shaft 202, and the two are screwed together, and the lower adjustment block 203 can be adjusted by rotating the inner adjustment shaft 202. Up and down positions; the side of the lower adjustment block 203 facing the guide sleeve is an inclined surface, and the inclined surface is attached to the outer wall of the guide sleeve.

[0030] In addition to the inner adjustment shaft 202 and the lower adjustm...

Embodiment 2

[0037] Embodiment 1 is the best embodiment of the present invention. In application, in order to simplify the structure and volume of the clearance eliminating device, the upper adjustment block 205 and the outer adjustment shaft 204 can be omitted, and only the lower adjustment block 203 and the inner adjustment shaft 202 remain.

[0038] In this embodiment, the specific structure of the gap eliminating device is as follows:

[0039] like Figure 8 As shown, the adjustment device I2 includes a pressure plate 201, an inner adjustment shaft 202 and a lower adjustment block 203; the lower adjustment block 203 is installed on the inner adjustment shaft 202, and the two are threaded, and the lower adjustment block 203 can be adjusted by rotating the inner adjustment shaft 202. The upper and lower positions; the pressure plate 201 has a shaft groove 204, and the inner adjustment shaft passes through the shaft groove 204; the side of the lower adjustment block 203 facing the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com