Continual mining working face equipment remote monitoring and control system

A technology of remote monitoring and control system, applied in general control system, control/regulation system, program control and other directions, can solve the problem that the operation and production status of continuous mining equipment cannot be grasped in real time, and the data of continuous mining production system cannot be saved, queried, and cannot be stored. Generate data reports and other issues to shorten the fault diagnosis time, improve the degree of automated information, and reduce on-site operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

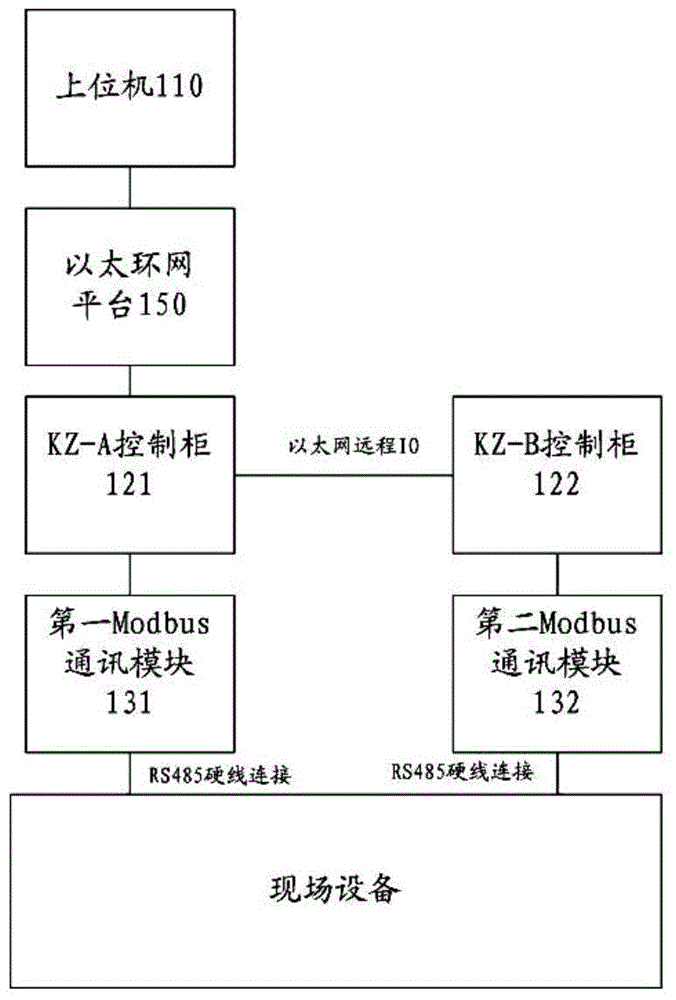

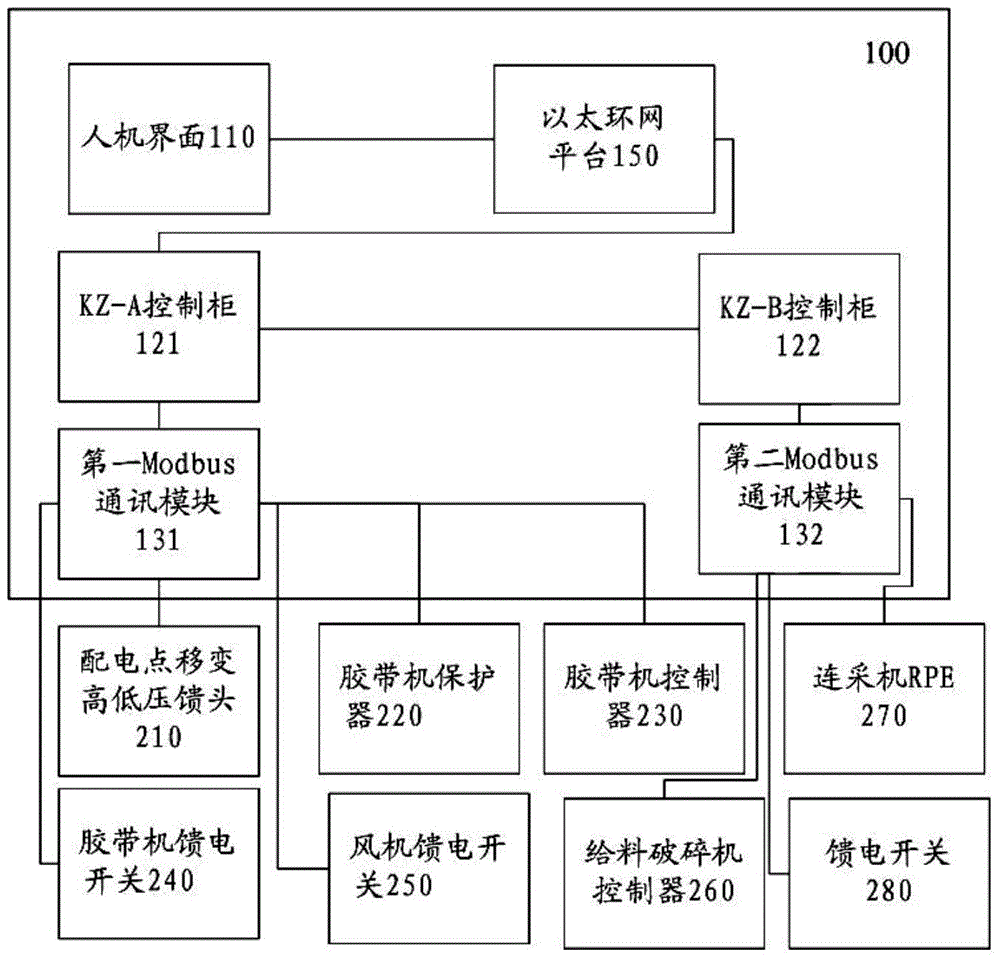

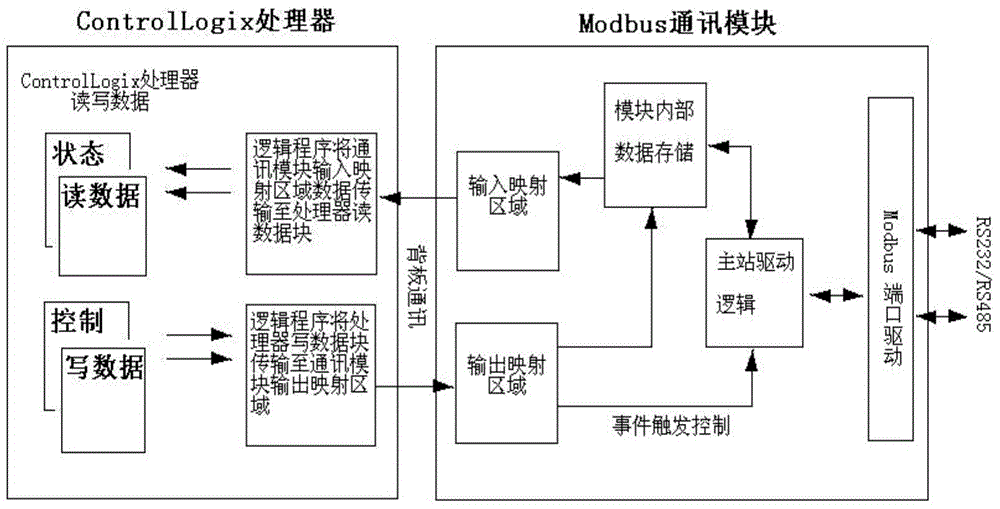

[0019] figure 1 It is a structural block diagram of the continuous mining face equipment remote monitoring and control system 100 of the present invention, which includes: a host computer 110, an Ethernet ring network platform 150, a KZ-A control cabinet 121, a KZ-B control cabinet 122, a first Modbus communication Module 131 and the second Modbus communication module 132; wherein, the KZ-A control cabinet 121 is connected to the host computer 110 through the Ethernet ring network platform 150, the KZ-A control cabinet 121 is equipped with a processor CPU, and the KZ-B control cabinet 122 It is the remote station of KZ-A control cabinet 121, and the two are connected by cables; and, KZ-A control cabinet 121 is electrically connected with field devices through the first Modbus communication module 131, and KZ-B contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com