Photovoltaic assembly installation structure for photovoltaic support

A photovoltaic module and photovoltaic support technology, which is applied to the support structure of photovoltaic modules, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of poor structural reliability and low strength, and achieve the effects of convenient installation, reasonable structure and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

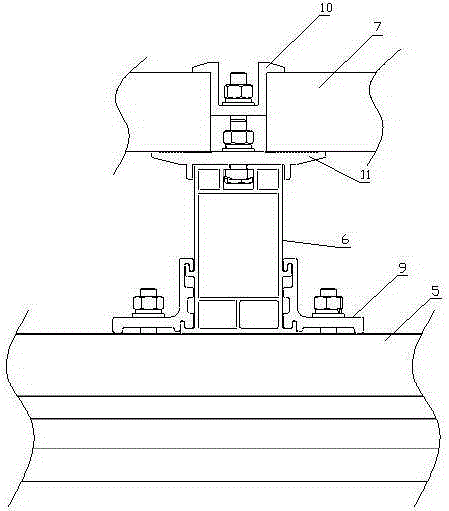

[0027] see Figure 1~Figure 5 , a photovoltaic module installation structure of a photovoltaic support related to the present invention, which includes a slanted beam 5, a crossbeam 6 and a photovoltaic module 7, the top of the slanted beam 5 is provided with a plurality of crossbeams 6, and the top of the slanted beam 5 is connected to the The crossbeam 6 is connected by a crossbeam fixing seat 9 , and the top of the crossbeam 6 is fixed to the photovoltaic module 7 by a pressure block 10 , wherein an anti-skid connection seat 11 is also provided between the pressure block 10 and the crossbeam 6 .

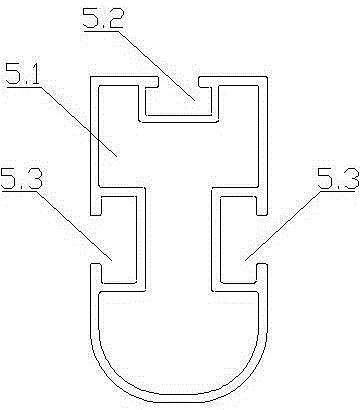

[0028] The inclined beam 5 includes an inclined beam cavity 5.1, the top of the inclined beam cavity 5.1 is provided with an inclined beam top installation slot 5.2, and both sides of the inclined beam cavity 5.1 are provided with an inclined beam side installation slot 5.3.

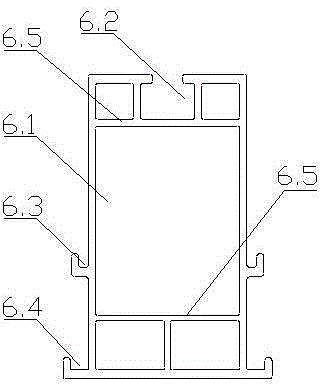

[0029] The beam 6 includes a beam cavity 6.1, the top of the beam cavity 6.1 is provided with a beam top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com