Roller arrangement comprising a scraper

A scraper and roller gap technology, applied in the scraper field of the roller device, can solve the problems of scraper material loss and wear increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

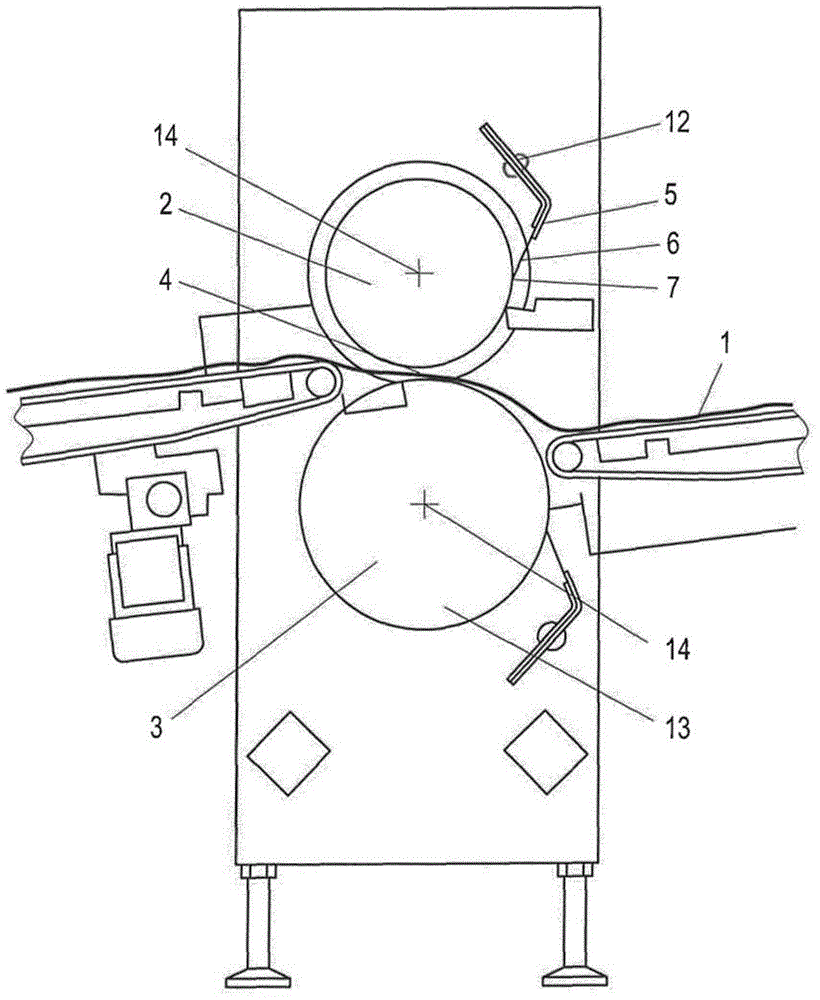

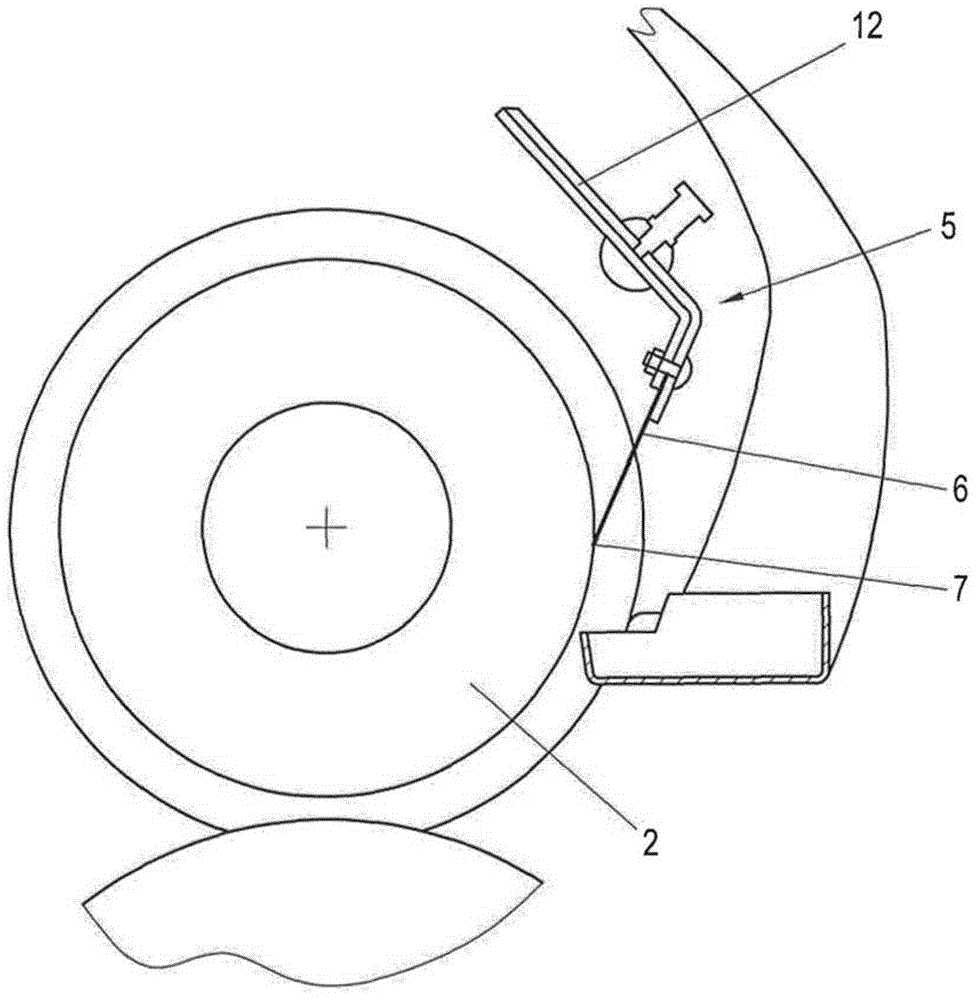

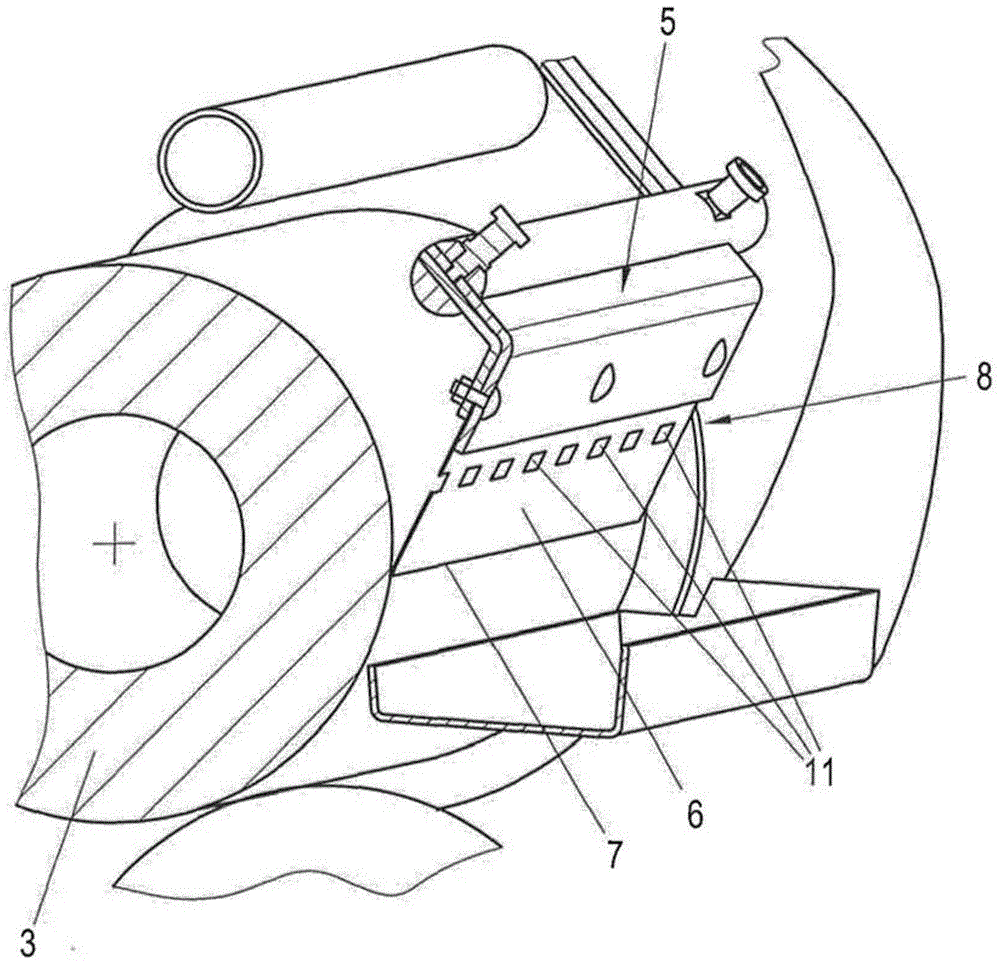

[0024] figure 1 One embodiment of the device according to the invention is shown. This device comprises a roll 2 , a counter body 3 and a roll gap 4 which is arranged between the roll 2 and the counter body 3 . The web 1 is guided through the roller gap 4 . In this illustration, the width of the roll gap is greater than that required for laminating the illustrated strip-shaped dough. Usually the width of the gap (ie the distance between the two rollers) corresponds substantially to the width of the strip-shaped dough formed.

[0025] In this embodiment, the counter body 3 is designed as a counter roller 13 . However, the counterpart body can optionally also be designed as a conveyor belt, a conveyor surface or the like.

[0026] Preferably, the drive roller 2 and the counter body 3 are driven such that the strip-shaped dough is conveyed through the roller gap. For example figure 1 In the present illustration, the strip-shaped blank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com