Pulling type wall cleaning, polishing, spraying all-in-one machine

A pulling type, all-in-one machine technology, applied in cleaning machinery, grinding/polishing equipment, machine tools suitable for grinding workpiece planes, etc., can solve problems such as low efficiency, unfavorable handling, non-uniform speed, etc., and achieve high work efficiency , novel structure, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

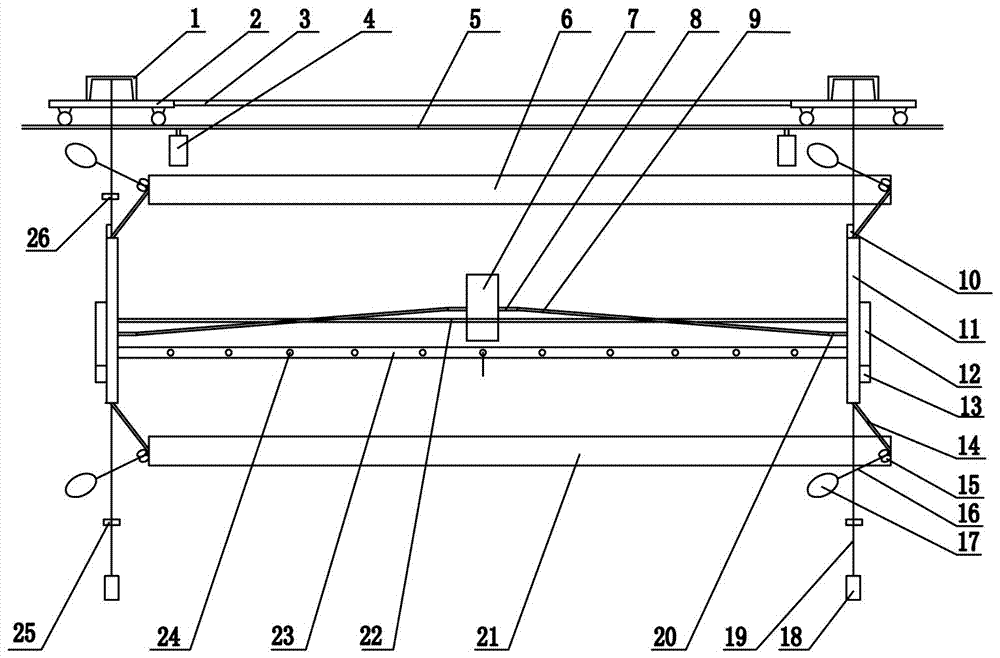

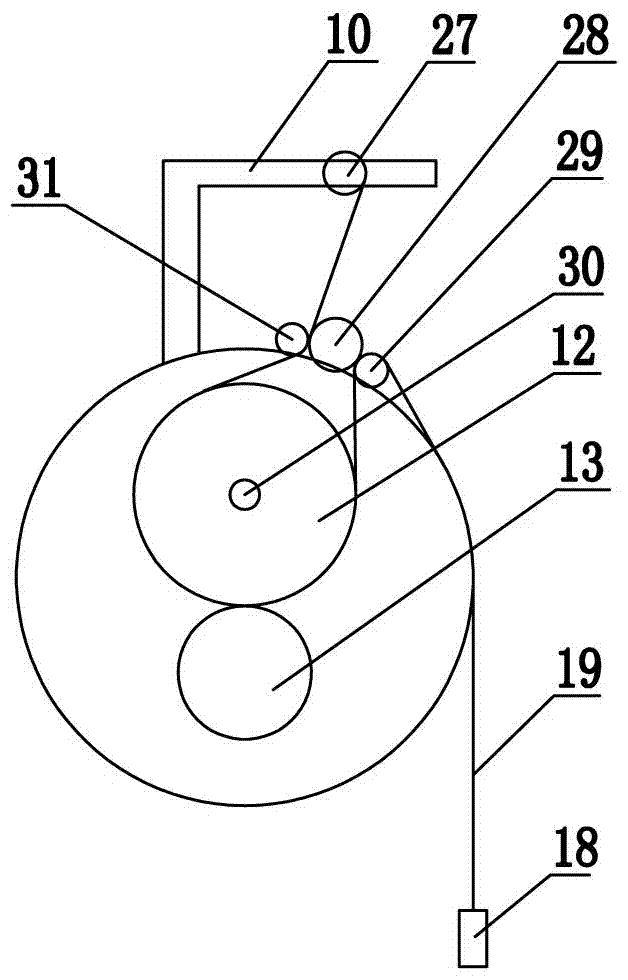

[0025] Such as figure 1 , 2 , 3 and 4, the pull-type wall cleaning, polishing, and spraying all-in-one machine of the present invention is characterized in that it includes a slide-rail type fixed mounting bracket, and a pull-type uniform-speed elevator connected to the slide rail type fixed mounting bracket , the high-speed polishing machine, the high-pressure spray device and the high-speed cleaning machine arranged on the pull-type constant-speed elevator, and the two surface obstacle-crossing devices respectively arranged on the two side supports 14 of the pull-type constant-speed elevator, also include a remote monitoring operating system connected to the slide rail type fixed installation bracket and the pull type constant speed elevator respectively,

[0026] The slide rail type fixed installation bracket includes a slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com