Novel milling machine housing

A cover and milling machine technology, applied in milling machine equipment, details of milling machine equipment, metal processing machinery parts, etc., can solve the problems of high safety factor and poor safety of milling machine cover, and achieve high safety factor, novel structure and guaranteed safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

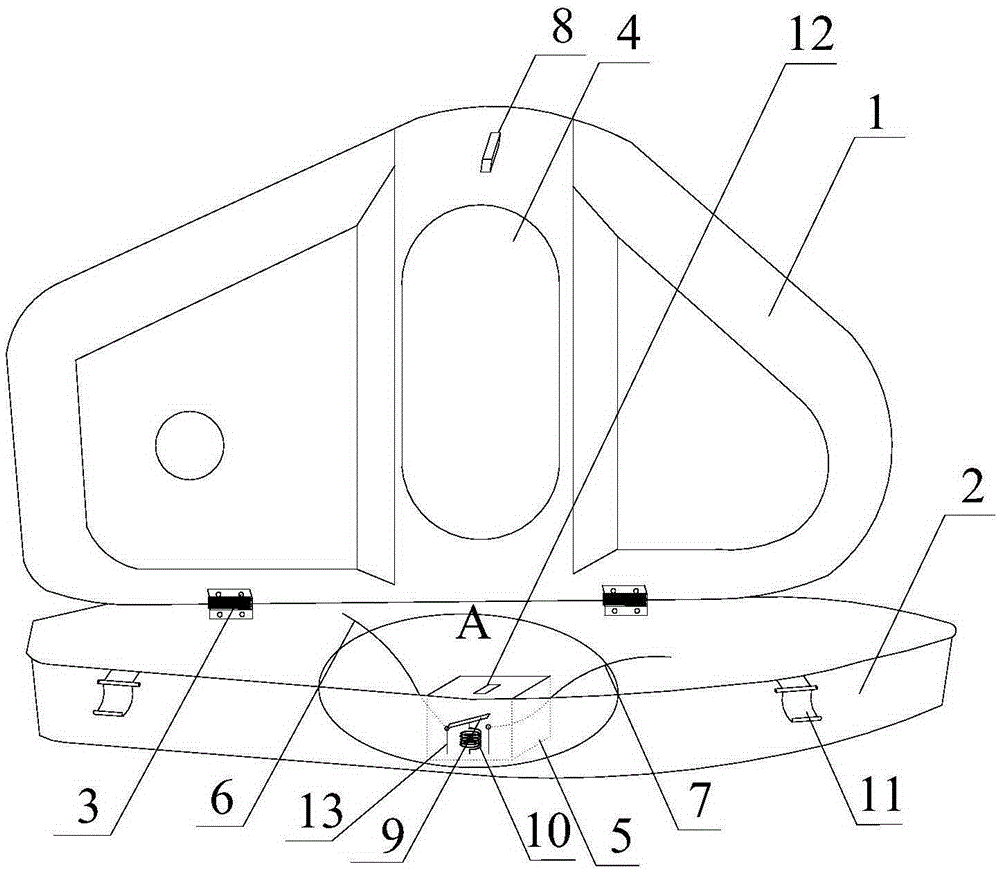

[0015] Below in conjunction with accompanying drawing, the present invention is further described:

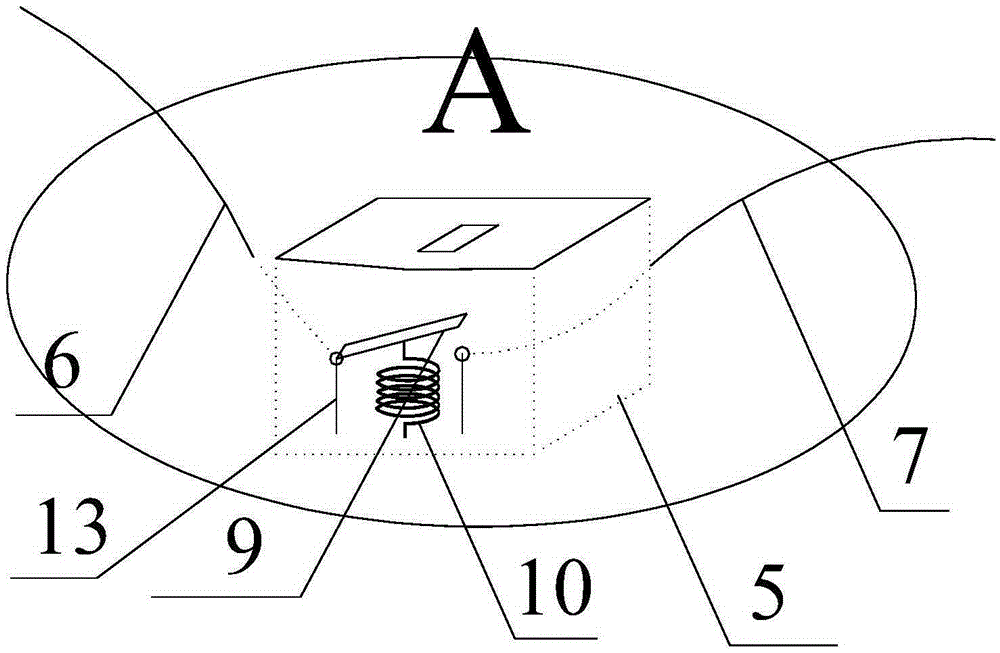

[0016] A new type of milling machine cover, including an upper cover 1 and a lower cover 2, the upper cover 1 and the lower cover 2 are connected by a hinge 3, a switch box 5 is arranged inside the lower cover 2, The switch box 5 is provided with a pressure piece 9, one end of the pressure piece 9 is connected to the line A6, the bottom of the pressure piece 9 is fixed on the bottom of the switch box 5 by a spring 10, and the other end of the pressure piece 9 A line B7 is provided below, a hole 12 is provided on the switch box 5, and a pressing block 8 is provided on the upper cover 1, and the pressing block 8 can pass through the hole 12 to press down and connect the other end of the pressing piece 9 to line B7.

[0017] One end of the wire A6 and the wire B7 is fixed by a support rod 13 , and the support rod 13 is fixed on the bottom of the switch box 5 .

[0018] The lower...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap