Web guiding mechanism and robot

A technology of deviation correction wheel and polishing machine, which is applied in the field of deviation correction mechanism and robot, and can solve the problems such as inability to adjust the deviation of the abrasive belt, and achieve the effects of simple and fast deviation correction, stable position of the abrasive belt, and simple adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

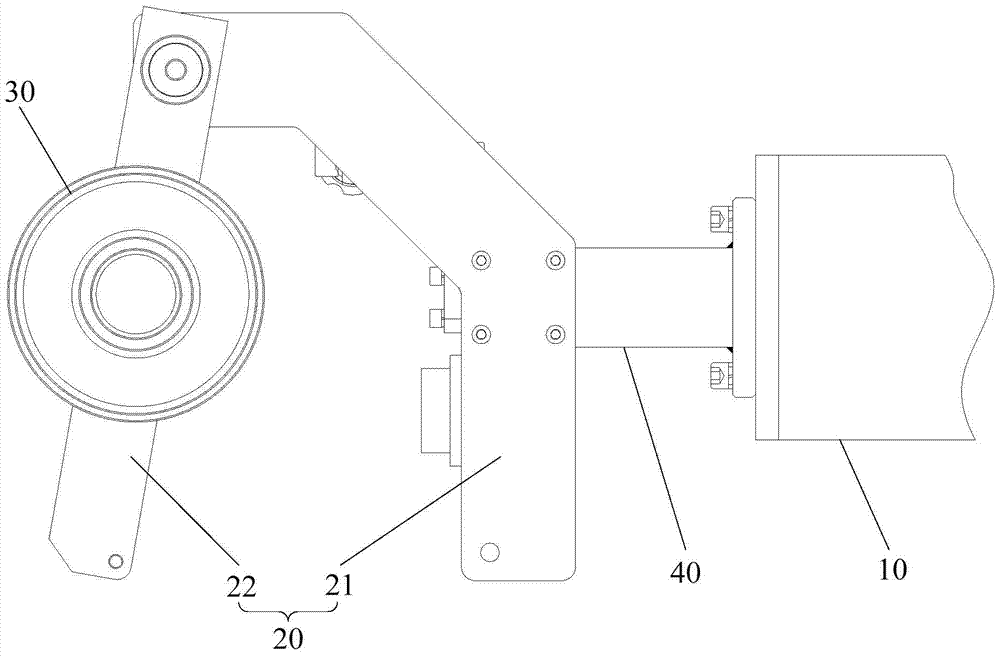

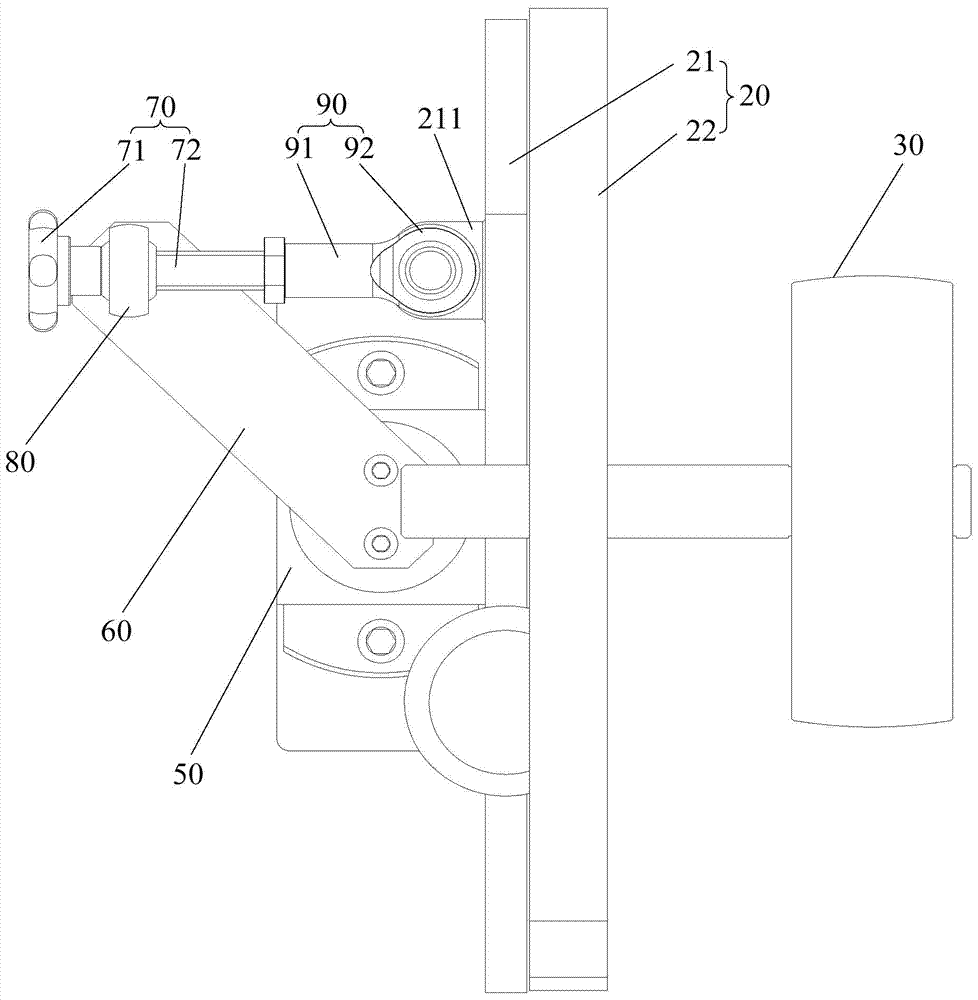

[0020] see figure 1 , figure 2 , propose an embodiment of the deviation correction mechanism of the present invention, wherein, figure 1 It is the front view of the deviation correction mechanism of the embodiment of the present invention, figure 2 It is the left view of the deviation correction mechanism in the embodiment of the present invention. The deviation correcting mechanism is mainly used in polishing machines for correcting and adjusting the abrasive belt during the polishing process. The deviation correction mechanism includes a frame 10, a bracket 20 and a deviation correction wheel 30, and a fixed shaft 40, a rotating sleeve 50, a pull rod 60 and an adjustable connecting rod are added. The deviation correction wheel 30 is connected to the support 20, and the support 20 is connected to rotate A shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com