Plate overturning device

A flap and frame technology, applied in the field of plywood production facilities, can solve the problems of high labor intensity, low efficiency, and many processes, and achieve the effects of high automation, high efficiency, and unique measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

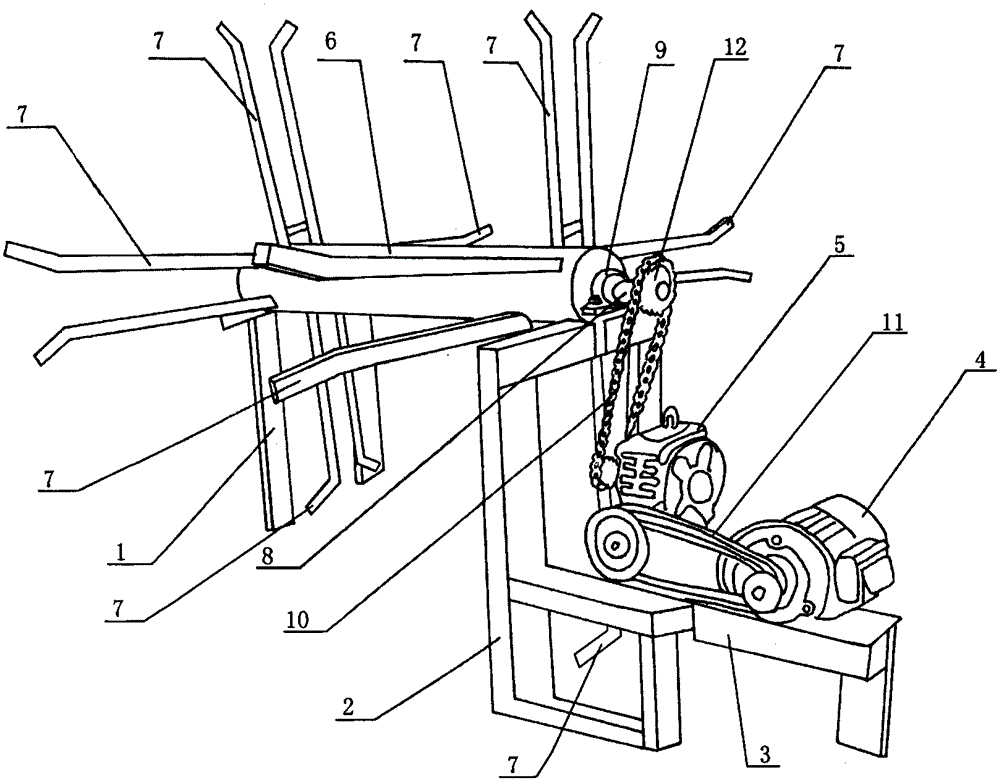

[0016] Now in conjunction with accompanying drawing, the present invention is described in detail:

[0017] The present invention is made up of frame body one (1), frame body two (2), motor frame (3), motor (4), servo motor (5), cylinder (6), flap frame (7), rotating shaft ( 8), bearing group (9), chain (10), belt (11) form.

[0018] figure 1 Shown is the structural representation of the present invention. Among them, 1 is frame one (1), 2 is frame two (2), 3 is motor frame (3), 4 is motor (4), 5 is servo motor (5), 6 is roller (6), 7 is a flap frame (7), 8 is a rotating shaft (8), 9 is a bearing group (9), 10 is a chain (10), 11 is a belt (11), and 12 is installed on one side of the rotating shaft Sprocket (12).

[0019] Turning frame (7) is made up of four pipes, and there are four groups of turning frame (7). The four pipes are arranged on the two ends of the drum (6) correspondingly with two on each side, and the four sets of flap frames (7) are correspondingly arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com