Eccentric cam rivet

An eccentric cam and rivet technology, applied in the direction of rivets, etc., can solve the problems of inability to perform fine adjustment and tightening, inability to achieve the mechanical properties of rivets, and the difficulty of automatic assembly of rivets, and achieve the effect of good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

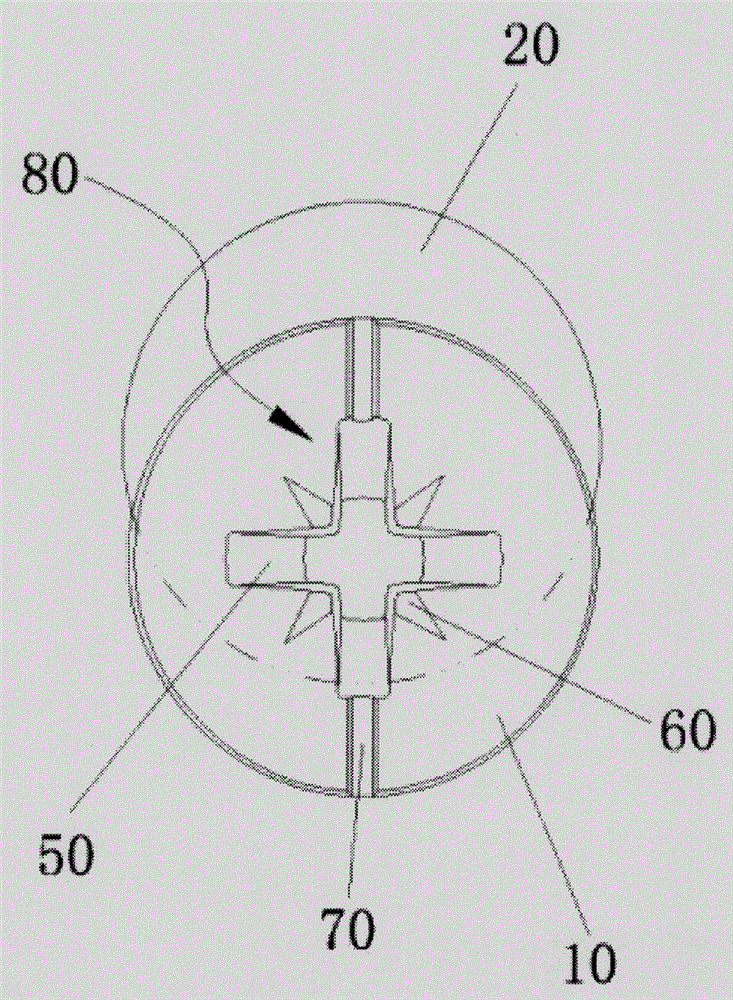

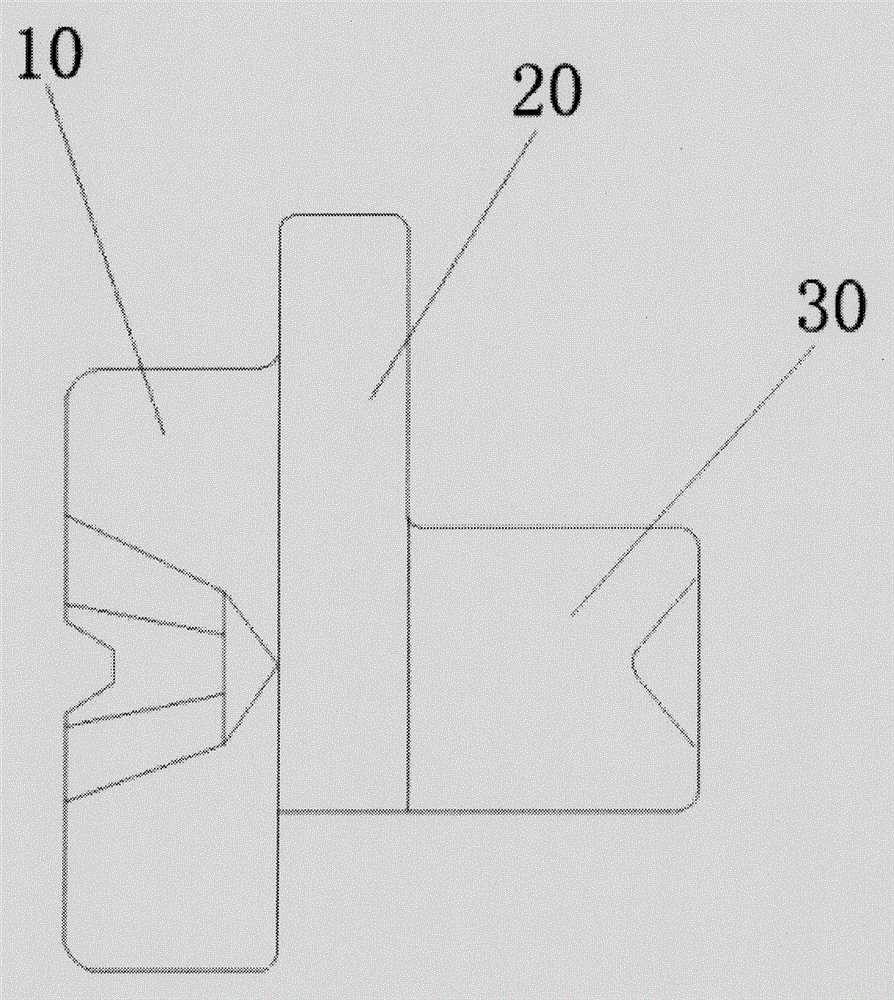

[0016] refer to figure 1 and figure 2 , an eccentric cam rivet, comprising a first cylindrical head 10, a second cylindrical head 20 is affixed to the lower part of the first cylindrical head 10, a nail rod 30 is affixed to the lower part of the second cylindrical head 20, the eccentric cam rivet It is made of carbon steel by multi-position cold heading. In this way, the eccentric cam rivet is easy to realize automatic assembly and has good mechanical properties.

[0017] The first cylindrical head 10 and the second cylindrical head 20 are connected in a non-axial structure, the first cylindrical head 10 and the nail rod 30 are in a coaxial structure, and the end of the first cylindrical head 10 is opened There is a tightening groove 80, the tightening groove 80 of the head of the eccentric cam rivet is formed by upsetting for many times with a special punching die, the shank 30 of the eccentric cam rivet is formed by upsetting the combined main mold, and the rivet formed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com