Flue fire damper for range hood

A technology for fire dampers and range hoods, which is applied to safety valves, balance valves, valve devices, etc., can solve the problems of large air outlet loss, complex structure, and large air outlet area of the passage, so as to reduce the blockage of the flue, work stably, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

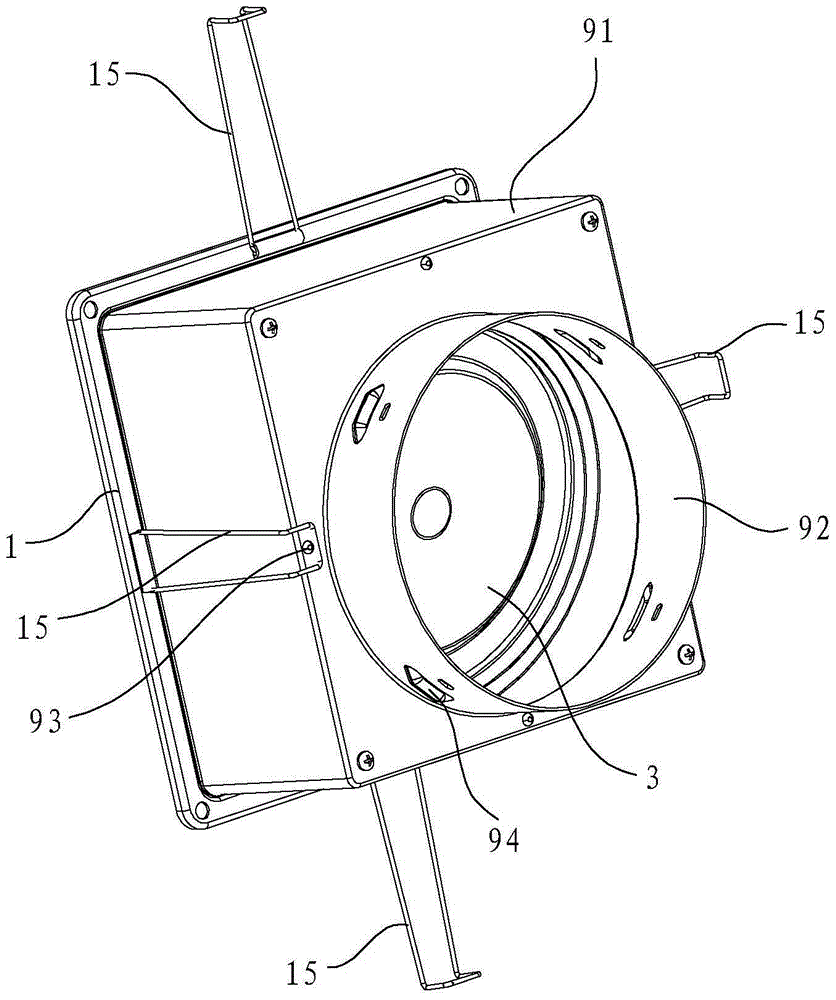

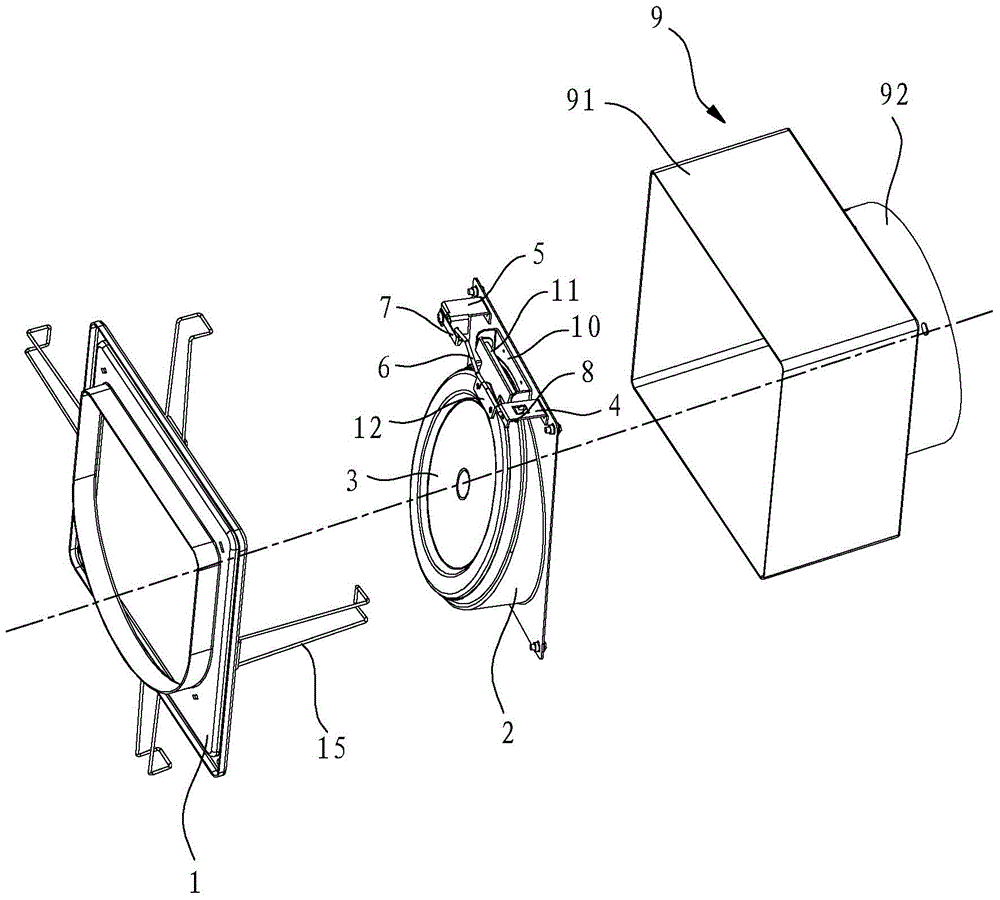

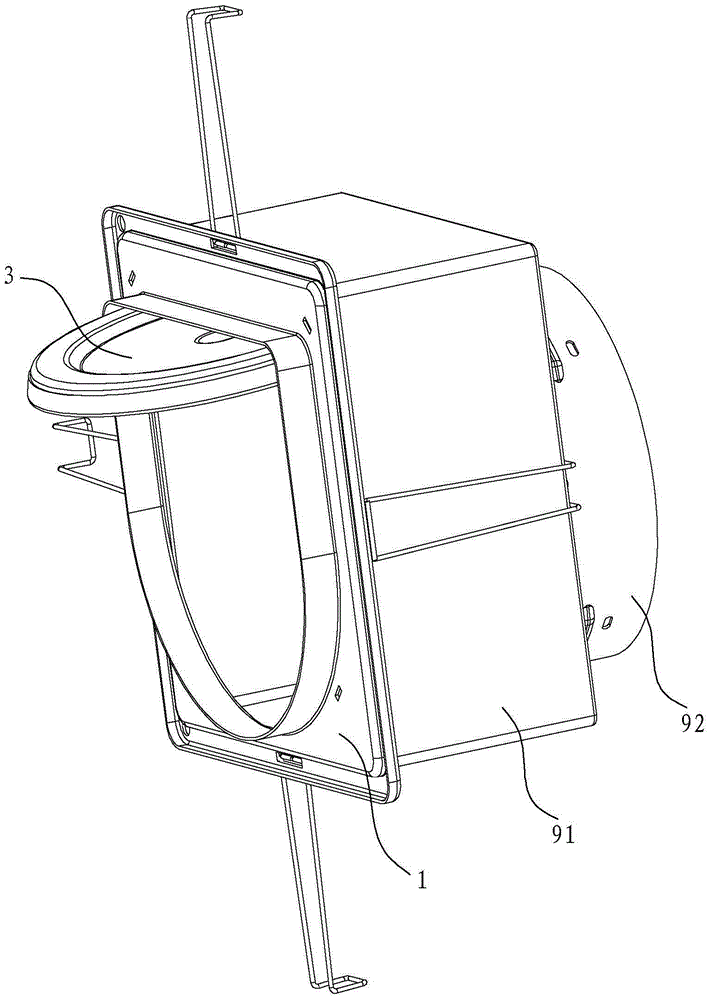

[0024] Such as Figure 1 to Figure 3 As shown, the flue fire damper for range hoods in this embodiment includes a fire damper bottom plate 1, a fire damper body 2, a fire damper sheet 3, a first bracket 4, a second bracket 5, a forced closing rod 6, and a deformation piece 7 , torsion spring 8, flue transition cover 9, installation shaft bracket 10, installation shaft 11, rotating connecting piece 12, fire damper sealing sleeve 13, magnet 14, fixed spring buckle 15 and gasket 16 and other main components.

[0025] The installation shaft bracket 10 is fixed on the fire damper body 2, the installation shaft 11 is arranged horizontally and installed on the installation shaft bracket 10, the rotating connecting piece 12 is installed on the installing shaft 10, and the top of the fire damper plate 3 is fixed on the rotating connecting piece 12 , T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com