Floodlighting suite of warehouse electric forklift

A technology for electric forklifts and flood lighting, which is applied to the components of lighting devices, electric light sources, lighting devices, etc., and can solve the requirements for the use, maintenance, and high maintenance costs of generator sets, reducing the efficiency and accuracy of material loading and unloading, and lighting requirements Especially harsh problems, to achieve the effect of fast driving speed, good light-gathering effect and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

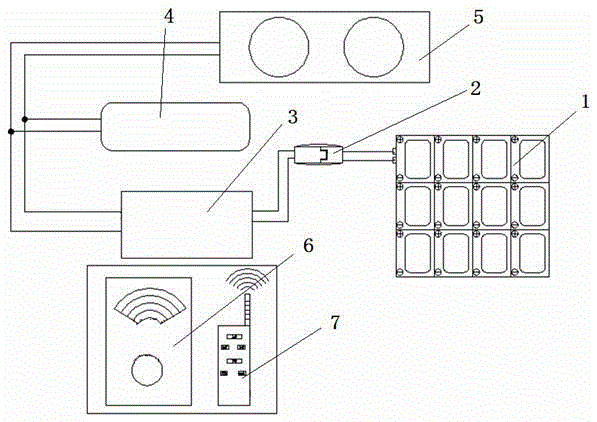

[0020] Embodiment: A warehouse electric forklift flood lighting kit (see figure 1 ), which includes electric forklift battery module 1, intelligent voice sensor 6 self-prepared dry battery for independent operation, lamp remote control 7, electric forklift battery module 1 is connected to mobile lighting lamp power conversion module 3 by closing control switch 2, and mobile lighting The lamp power conversion module 3 is respectively connected to the fully automatic electric self-cruising slide rail platform 4 and the self-priming remote control floodlight group 5, the lamp remote control 7 matches the self-priming remote control floodlight group 5, and the self-priming is controlled by radio Type remote control floodlight group 5 work.

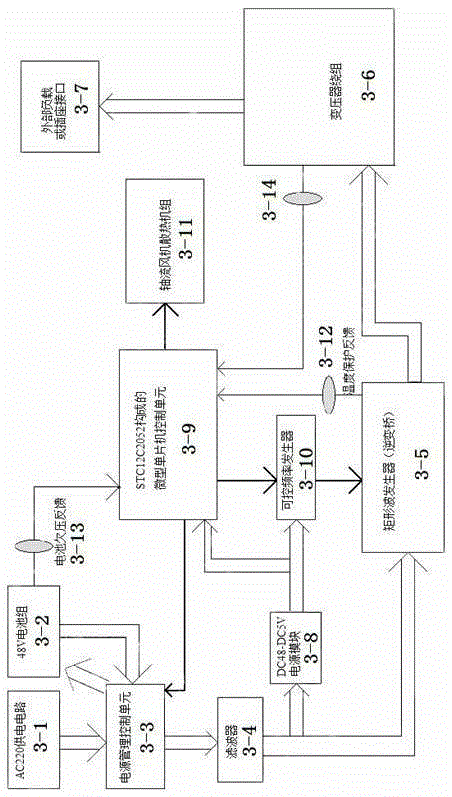

[0021] Mobile lighting fixture power conversion module 3 (see figure 2 ) includes a micro-single-chip microcomputer control unit 3-9 composed of STC12C2052, and the micro-single-chip microcomputer control unit 3-9 is respectively connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com