Triangular protruding stab plate-fin heat exchanger

A triangular and thorn technology, applied in the F28D heat exchanger and heat exchanger field, can solve the problems of reducing the average liquid film, the effect is not obvious, the condensation heat transfer process and mechanism are complicated, and achieve energy saving and easy processing. , Improve the effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0047] In this article, if there is no special explanation, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication.

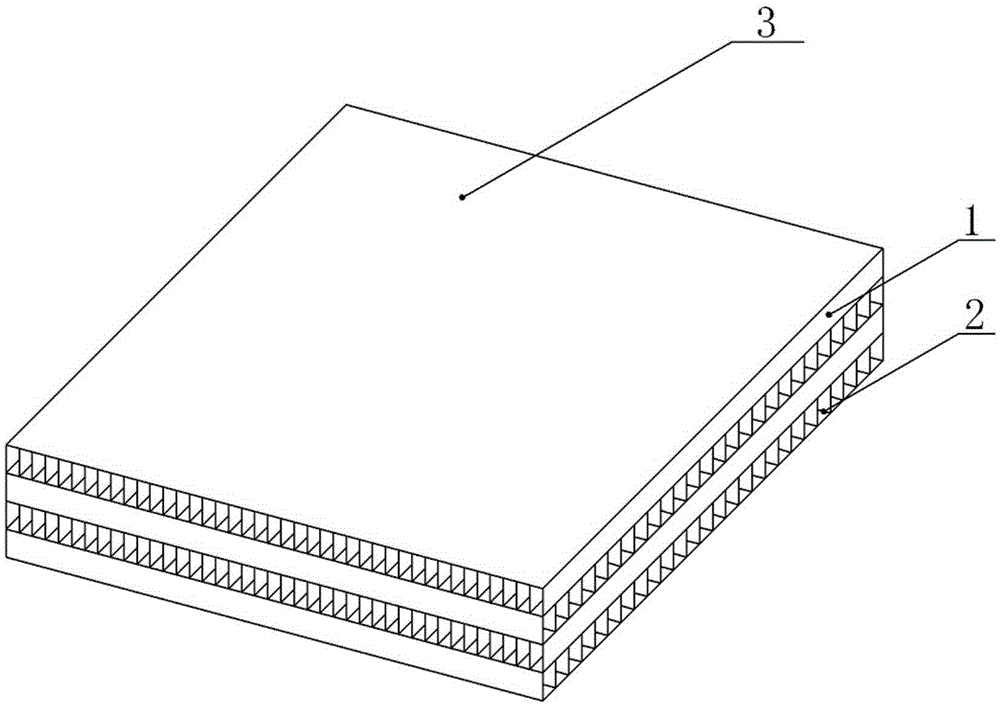

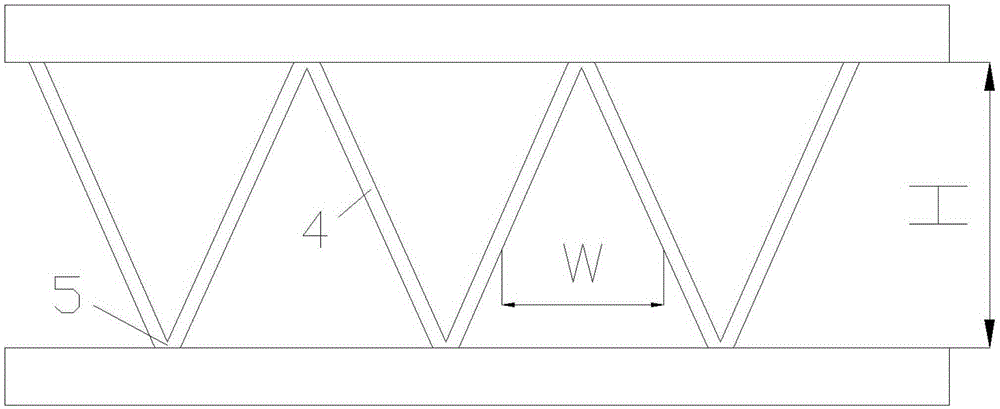

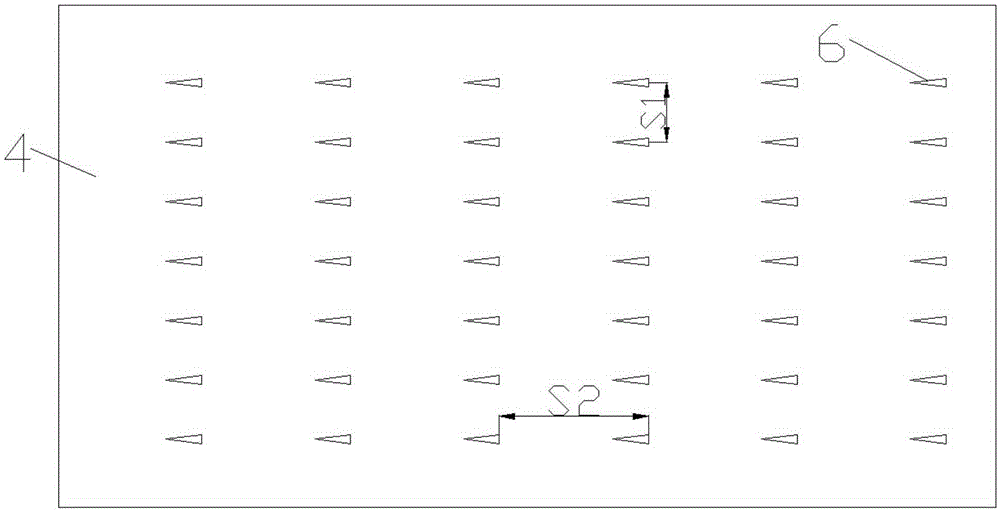

[0048] Such as figure 1 As shown, a plate-fin heat exchanger for the condensation of non-azeotropic multi-component mixtures, the plate-fin heat exchanger includes plates 3 parallel to each other, and the adjacent plates 3 form a In the fluid channel 2, fins 7 are arranged between the adjacent plates 3. The fins 7 include an inclined part 4 inclined to the plate 3, and the thorns 6 are processed on the inclined part 4 by stamping, so that the fluid on both sides of the inclined part 4 can communicate through the holes formed by stamping on the inclined part 4; The spurs 6 extend outwards from the inclined portion 4 .

[0049]By setting the stab 6, it has the following advantages:

[0050] 1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com