A friction testing machine applied to printed objects

A technology of friction testing machine and printed matter, which is applied in the direction of testing wear resistance, etc., can solve the problems of short service life and influence on friction test results, etc., and achieve the effect of long service life, ingenious structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

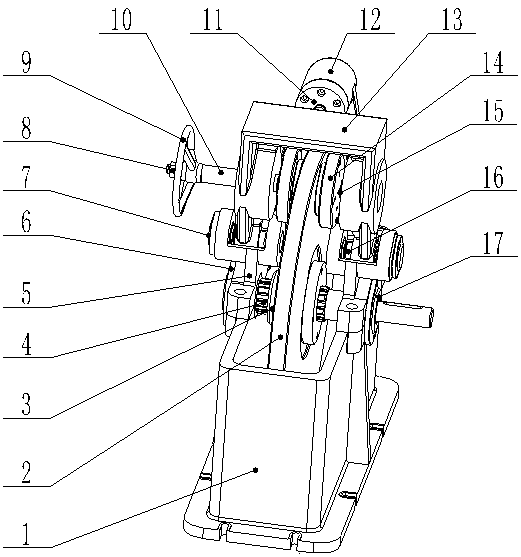

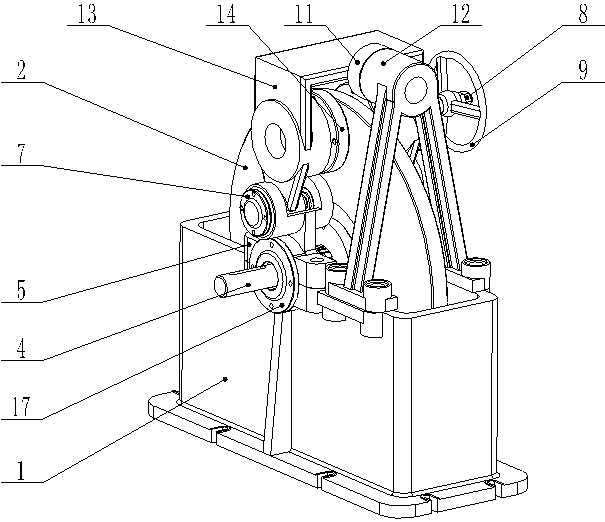

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0013] Example. A friction testing machine applied to printed objects, the composition of which is as follows figure 1 and 2 As shown, it includes a base 1 with a groove, a driving shaft 4 is arranged in the groove of the base 1, a connecting disc 3 is arranged in the middle of the driving shaft 4, a wheel disc 2 is arranged on the connecting disc 3, and the two sides of the wheel disc 2 All are provided with a test disc 14, and the test disc 14 is connected and fixed by bolts; the base 1 is provided with a bracket 5, and the two ends of the driving shaft 4 are respectively provided with a first baffle plate 6 and a second baffle plate 17 fixed on the bracket 5 , the support shaft 16 is provided on the support shaft 16, the U-shaped support 13 is provided on the support shaft 16, the top shaft 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com