Modular multilevel converter and converter module

A technology of converters and sub-modules, applied in the field of converters, can solve the problems of large loss and long dynamic response time, and achieve the effects of fast dynamic response, good comprehensive performance, and good DC fault ride-through capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

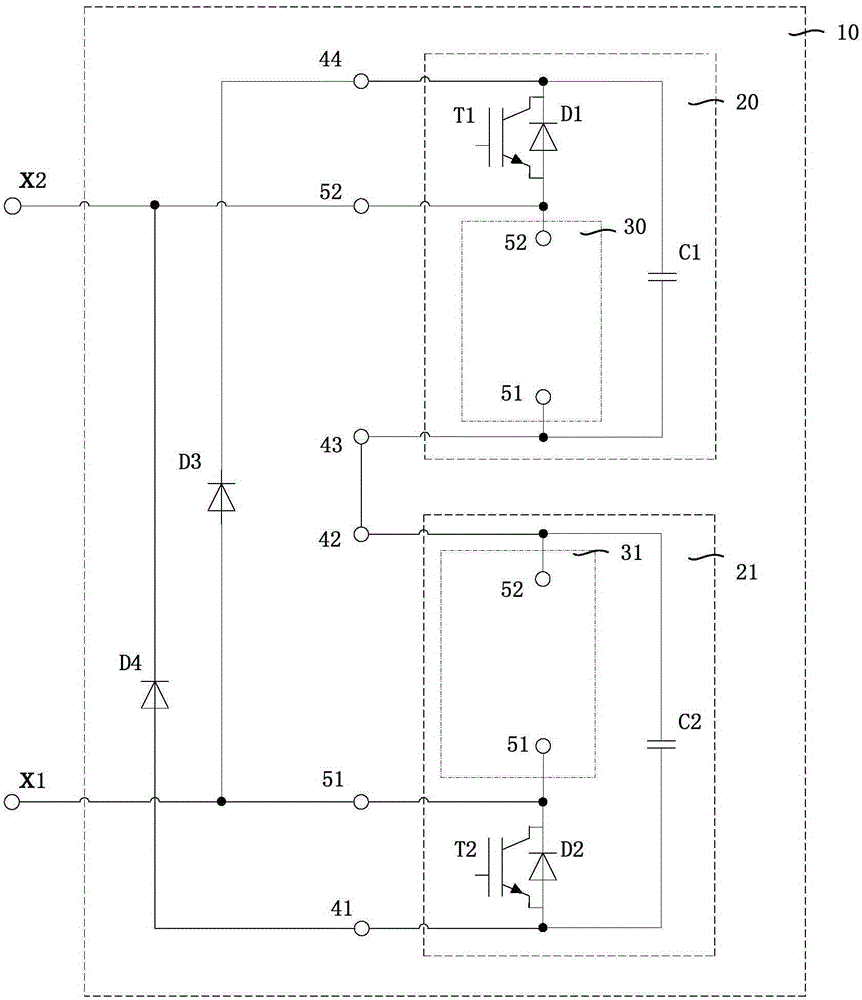

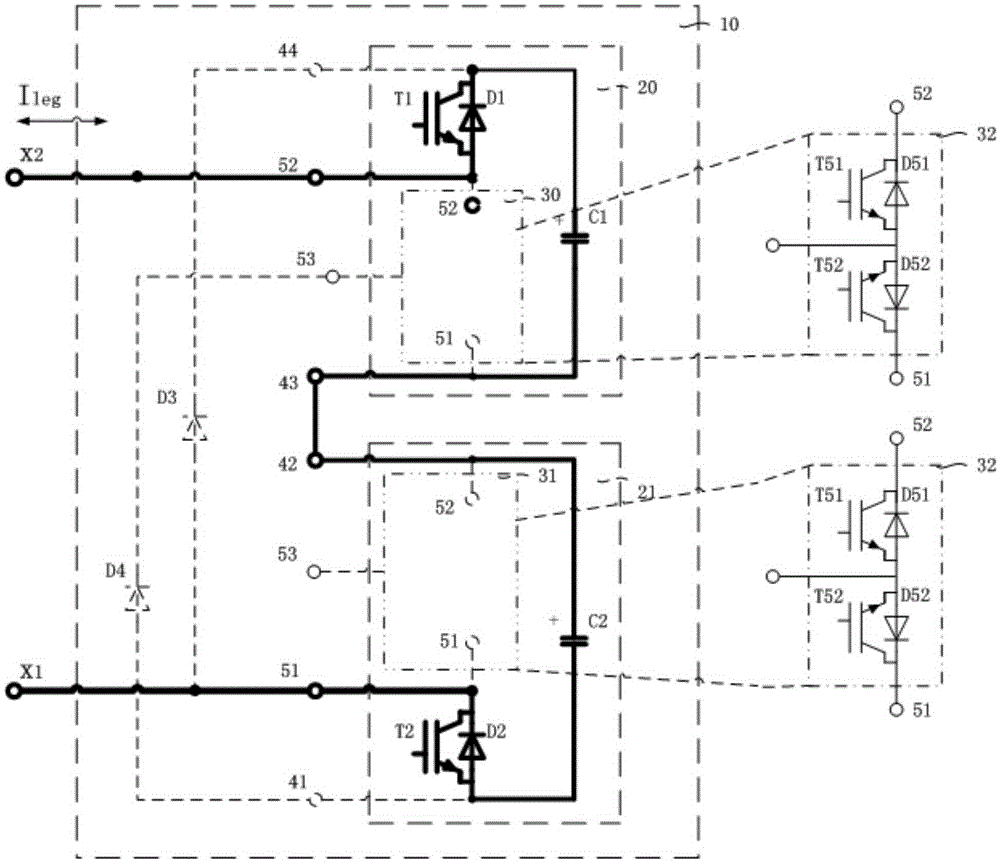

[0065] Such as figure 1 As shown, the converter module includes a first terminal X1, a second terminal X2, a diode D3, a diode D4, a first half-bridge 20 and a second half-bridge 21, and the first half-bridge 20 includes a first switch unit 30. The first switch module and the energy storage element C1, the first switch module and the energy storage element C1 are connected in parallel at both ends of the first switch unit 20; the second half bridge 21 includes a second switch unit 31, a second switch module and the energy storage element C2, the second switch module is connected in parallel with the energy storage element C2 at both ends of the second switch unit 31; the negative pole of the energy storage element C1 is connected to the positive pole of the energy storage element C2;

[0066] The anode of the diode D3 is connected to the first terminal X1, and the cathode is connected to the node of the first switch module and the energy storage element C1;

[0067] The cath...

Embodiment 2

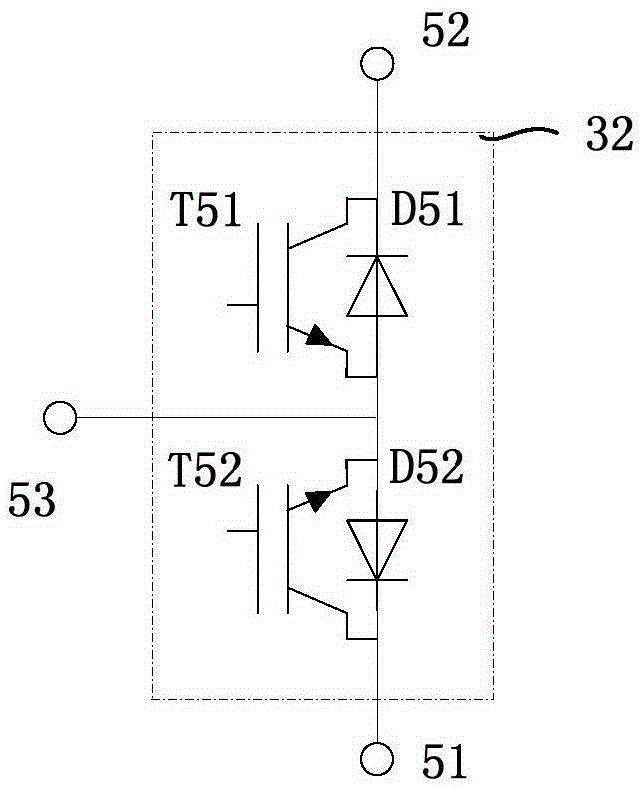

[0078] The difference from Embodiment 1 is that the first switch unit 30 and the second switch unit 31, such as Figure 6 As shown, the first switch unit 30 and the second switch unit 31 include two switch unit sub-modules connected in reverse series.

[0079] The switch unit sub-module includes a switch tube T53 and an antiparallel diode D53, or a switch tube T54 and an antiparallel diode D54. and remember as Figure 6 As shown, the module formed by connecting the collectors of the switch tubes in the two switch unit sub-modules is a switch unit 33, that is, the first switch unit 30 adopts the circuit of the switch unit 33, and the second switch unit 31 also adopts the switch unit 33 circuit.

Embodiment 3

[0081] The difference from Embodiment 1 is that the second switch unit 31, such as Figure 7 As shown, the second switch unit (21) includes a switch unit submodule, and the switch unit submodule includes a switch tube T55 and an antiparallel diode D55, and is recorded as Figure 7 As shown, one switch unit sub-module is the switch unit 34 , that is, the first switch unit 30 adopts the circuit of the switch unit 32 , and the second switch unit 31 adopts the circuit of the switch unit 34 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com