Tuberous root crop harvester

A rhizome and harvester technology, which is applied to digging harvesters, harvesters, excavators, etc., can solve the problems of limited soil removal effect and inability to complete root cutting work, and achieve the effect of prolonging service life and improving harvesting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

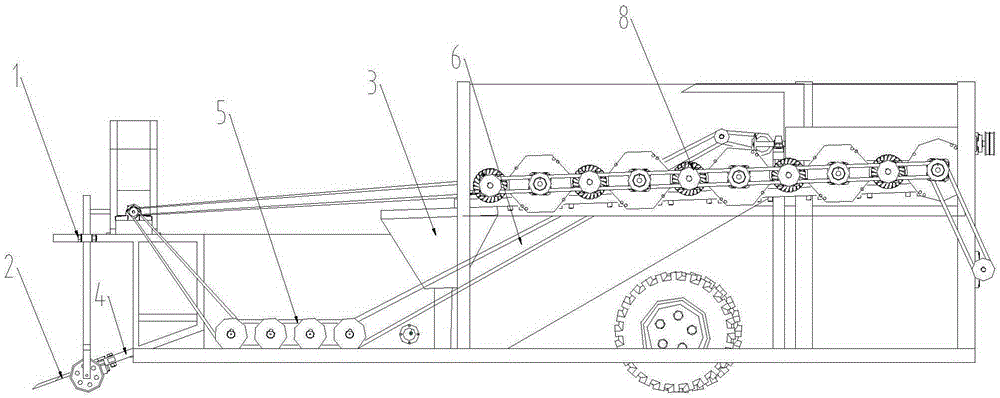

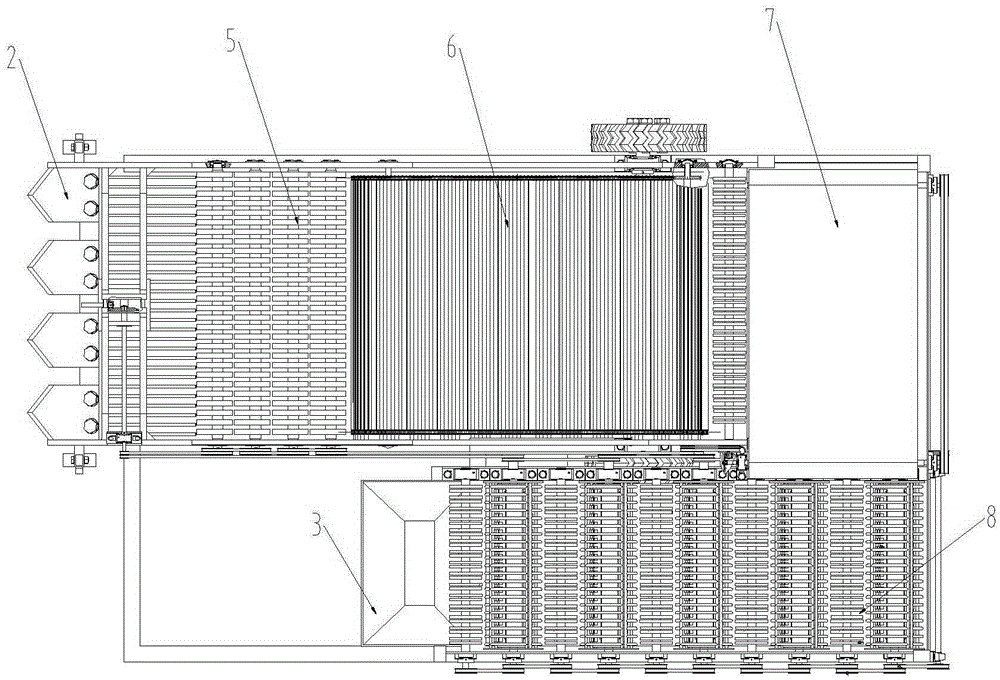

[0029] Such as figure 1 and figure 2 As shown, the massive rhizome crop harvester includes a frame 1, a digging shovel 2 and a collection box 3, and the digging shovel 2 is installed on the front end of the frame 1 through the digging shovel supporting plate 4, and also includes a soil removal device 5, a scraper type lift Conveyor 6, transverse conveyor belt 7 and root cutting device 8; digging shovel 2, soil removal device 5, scraper type elevator 6, and transverse conveyor belt 7 are arranged on one side of frame 1 from front to back, and root cutting device 8 And the collection box 3 is arranged on the other side of the frame 1 from front to back; the excavating shovel supporting plate 4 joins with the soil removing device 5 through a bridge, and the transverse conveyor belt 7 and the root cutting device 8 laterally join.

[0030] Su...

Embodiment 2

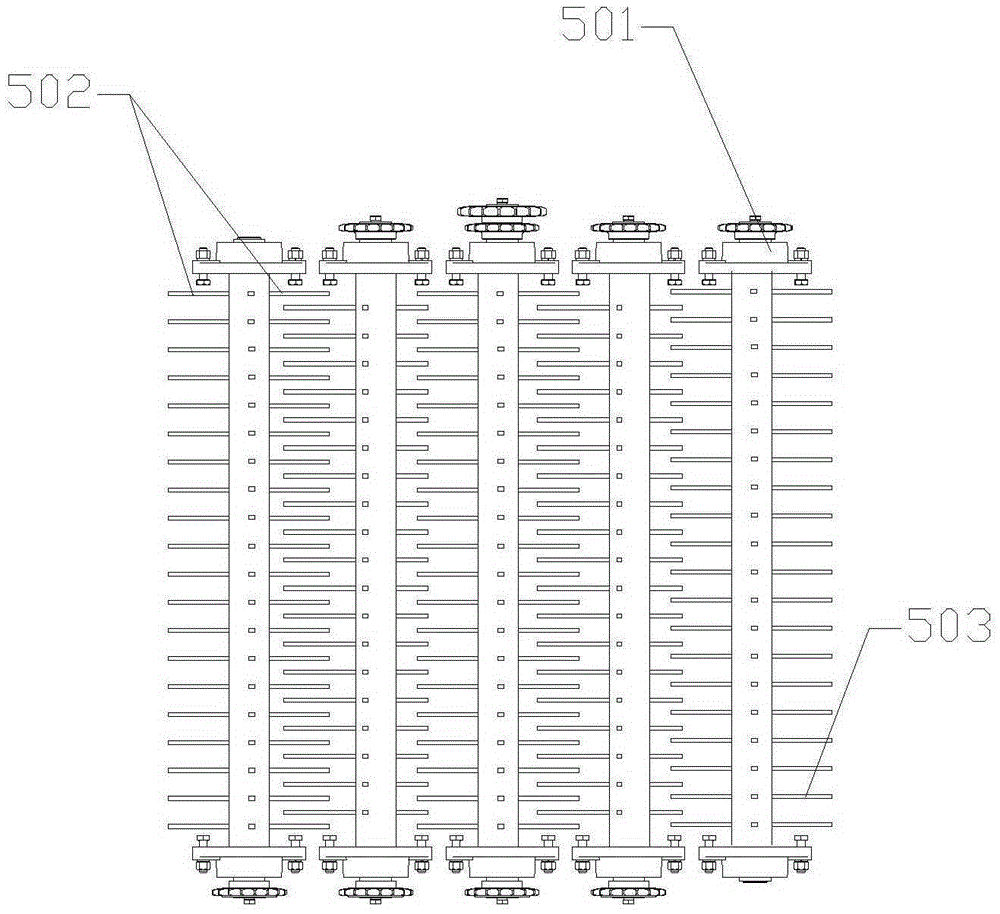

[0036] Different from the above embodiments, a ratchet transmission mechanism 9 is provided between the scraper elevator 6 and the transverse conveyor belt 7 , and the structure of the ratchet transmission mechanism 9 is the same as that of the ratchet shaft 801 in the root cutting device 8 . It includes a ratchet transmission shaft 901 and a plurality of ratchet groups 902 installed on the ratchet transmission shaft 901 , each ratchet group 902 includes two ratchets 903 , and the pawls of the two ratchets 903 are arranged alternately. During the process of the crops moving from the scraper elevator 6 to the horizontal conveyor belt 7, the ratchet transmission mechanism 9 plays a transitional role, and the ratchet 903 further desoils the crops while pushing the animals backward.

Embodiment 3

[0038] Different from the above embodiments, this embodiment provides a new cutter assembly structure.

[0039] The cutter assembly includes a plurality of "Y" shaped cutters 806 arranged along the circumference of the cutter, and the cutter is installed on the cutter shaft 802 through the vertical part of the "Y" shape. Detachable; the cutter blade 807 is located on the outer edge of the two bifurcated parts of the "Y" shape. During work, the blade 807 on one side of the cutter 806 performs cutting work. When the blade 807 on one side is worn out, the cutter 806 can be removed, and the direction of the cutter 806 can be rotated so that the blade 807 on the other side can perform the cutting work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com