Glass cabinet support drill jig

A technology for glass cabinets and drilling molds, which is applied in the direction of drilling molds for workpieces, etc., which can solve the problems of casing drilling of glass cabinet supports, etc., and achieve the effect of easy pushing and pushing of pressing blocks, not easy to be damaged, and simple connection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

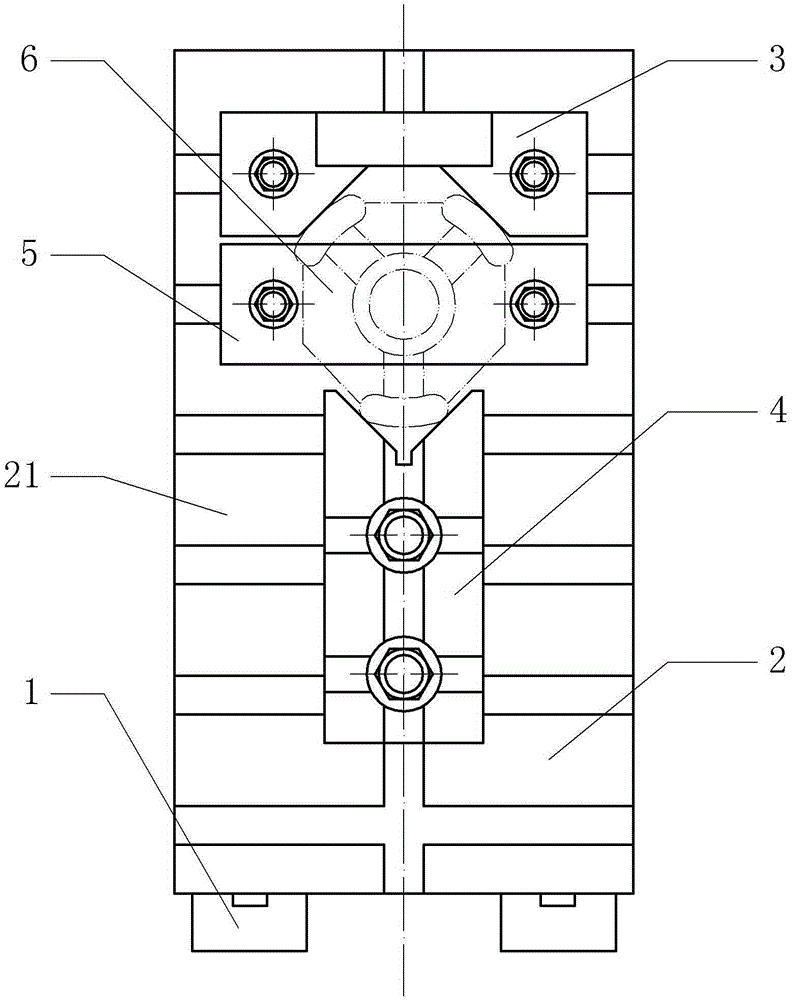

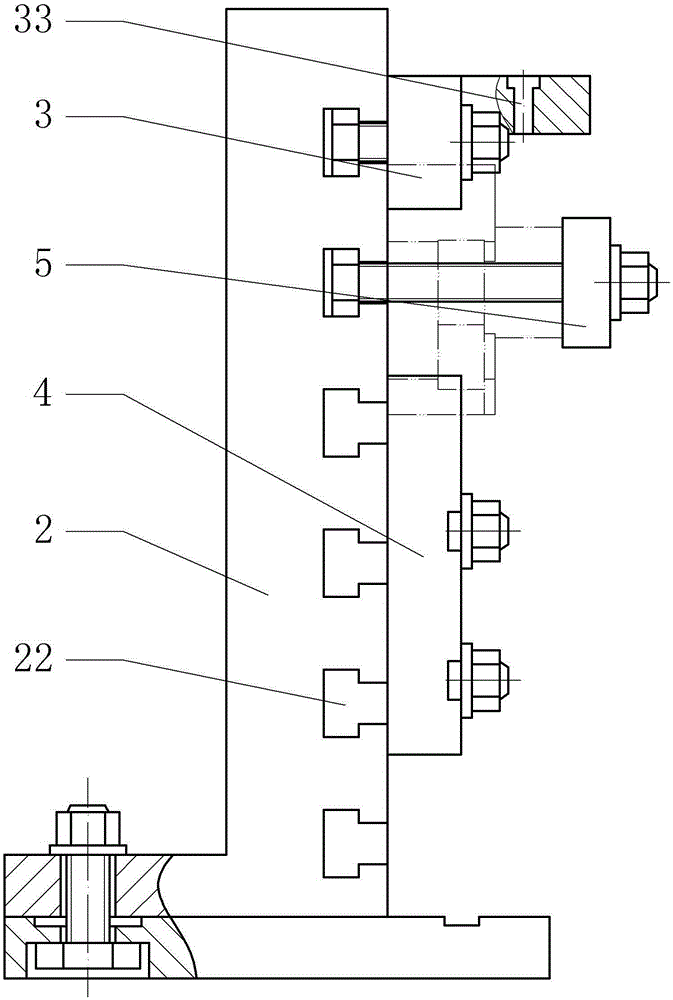

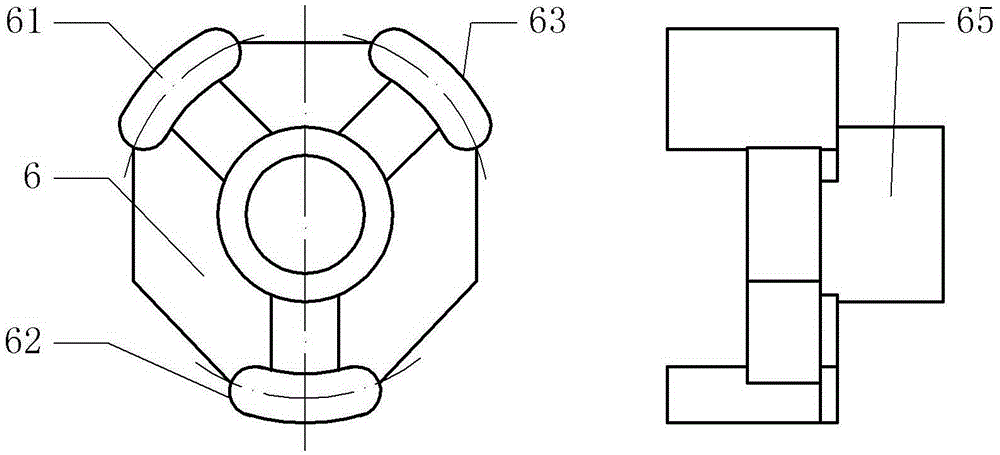

[0017] The embodiment is basically as attached figure 1 , figure 2 , image 3 As shown: the glass cabinet support drilling mold includes a mounting base 2, a fixing part and a pressing part 5; the mounting base 2 is fixedly connected to the vertical drilling machine workbench 1 by bolts, and the mounting base 2 has a vertical and horizontal mounting surface 21, The mounting surface 21 is provided with a T-shaped slot 22 in which the vertical direction and the horizontal direction alternate. The fixed part includes a fixed seat 3 and a push block 4. The fixed seat 3 is fixed on the mounting surface 21 of the mounting seat 2 by bolts, and the bolt heads of the bolts are inserted into the T-shaped groove 22. The fixed seat 3 is provided with mounting holes. , the mounting holes are inserted into the bolts and tightened with nuts to achieve fixation; the fixing seat 3 also has a V-shaped concave surface, which is a limiting concave surface, the V-shaped concave surface is at ri...

Embodiment 2

[0020] as attached Figure 4 The difference between the second embodiment shown and the first embodiment is that the push block 4 is connected to the mounting surface 21 of the mounting seat 2 by two bolts, and the bolt heads of the bolts are snapped into the horizontal T on the mounting surface 21. In the shaped groove 22, the push block 4 is sleeved on the bolt and locked with a nut, and the connection hole between the push block 4 and the bolt is a bar-shaped hole 41 parallel to the vertical direction.

[0021] Embodiment 2 The clamping process of the glass case support 6 is the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com