Slope workbench special for wire connection of installation boards

A technology of workbench and installation board, which is applied in the direction of workbench and manufacturing tools, can solve the problems of fatigue and low production efficiency of workers, and achieve the effects of ensuring work efficiency, saving land cost and reducing fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

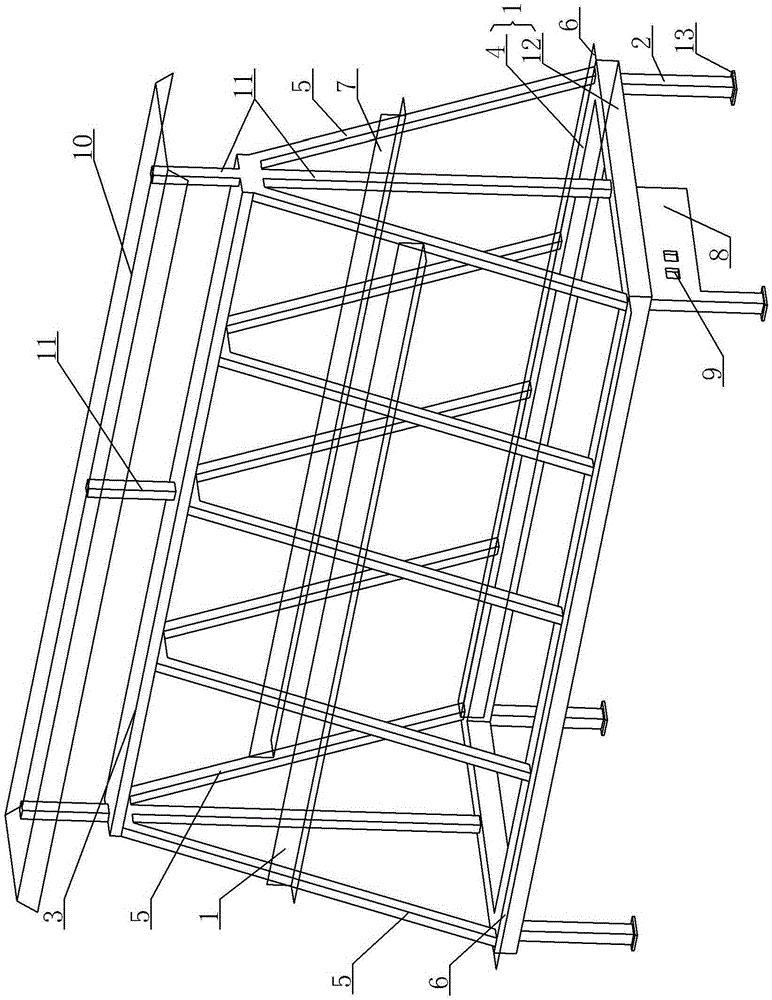

[0015] A sloped workbench specially used for mounting board wiring, see figure 1 : It includes a base 1, the base 1 is provided with supporting feet 2, a top beam 3 is arranged above the base 1, the top beam 3 is arranged parallel to the two sides 4 of the base 1, and the top beam 3 and the two sides 4 are respectively arranged There are several parallel connecting inclined beams 5, and the lower fixing plates 6 are respectively fastened on the two sides of the base 1, and it also includes upper fixing plates 7 on both sides of the top beam 3, and the upper fixing plates 7 on both sides are respectively located on the lower The height between the fixed plate 6 and the top beam 3, the upper fixed plate 7 is welded and connected to the connecting inclined beam 5 at the corresponding position, and the upper fixed plate 7 is arranged parallel to the lower fixed plate 6.

[0016] An installation connecting plate 8 is welded in the space between the bottom of the base 1 and any supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com