Textile machine

A technology for textile machines and workstations, which is applied in the direction of textiles, looms, and spinning machines. It can solve problems such as stoppage, insufficient monitoring of power supply units, and production stoppage of textile machines, so as to reduce energy consumption, prevent complete stoppage of production, and reduce The effect of small energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

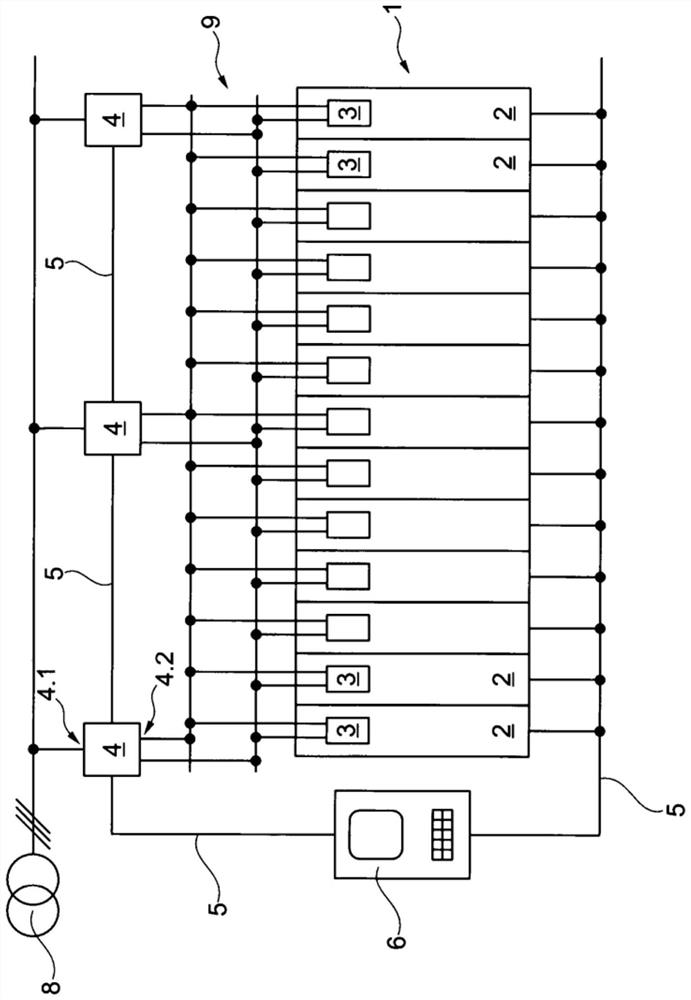

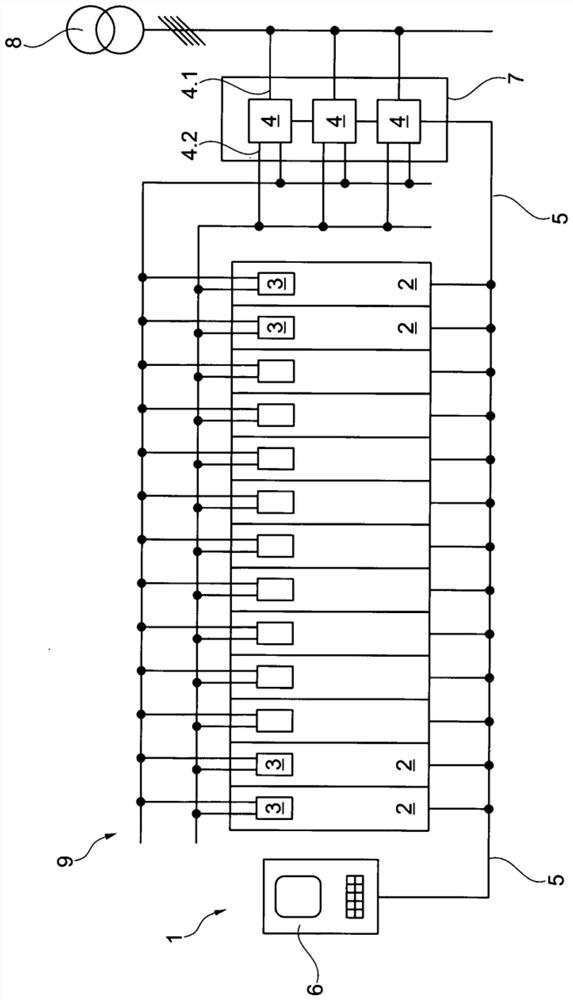

[0034] figure 1 A schematic diagram of the textile machine 1 of the present invention is shown. The textile machine 1 comprises a large number of work stations 2 arranged side by side. The station 2 can be designed, for example, as a winding position in a manner known per se. figure 1 As an example, only one power consumer 3 is shown per workstation 2 . The power consumer 3 is preferably designed as an electric drive. The textile machine 1 is provided with a Direct-voltage bar 9 along the length of the machine. The consumer 3 and possibly other not shown consumers of the workstation 2 are connected to a DC voltage rail for supplying electrical energy.

[0035] Distributed over the length of the textile machine 1 , a plurality, in this embodiment three, of power sources 4 are arranged, which together form a power supply unit of the textile machine 1 . In the exemplary embodiment shown, the power supply 4 is designed as a rectifier with a downstream DC voltage intermediate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com