Workbench with copper bar bending machine

A workbench and curved row technology, applied to workbenches, manufacturing tools, etc., can solve the problems of decreased work efficiency of workers, disruption of on-site work order, and easy separation of products, so as to ensure work order, reduce fatigue, and ensure work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

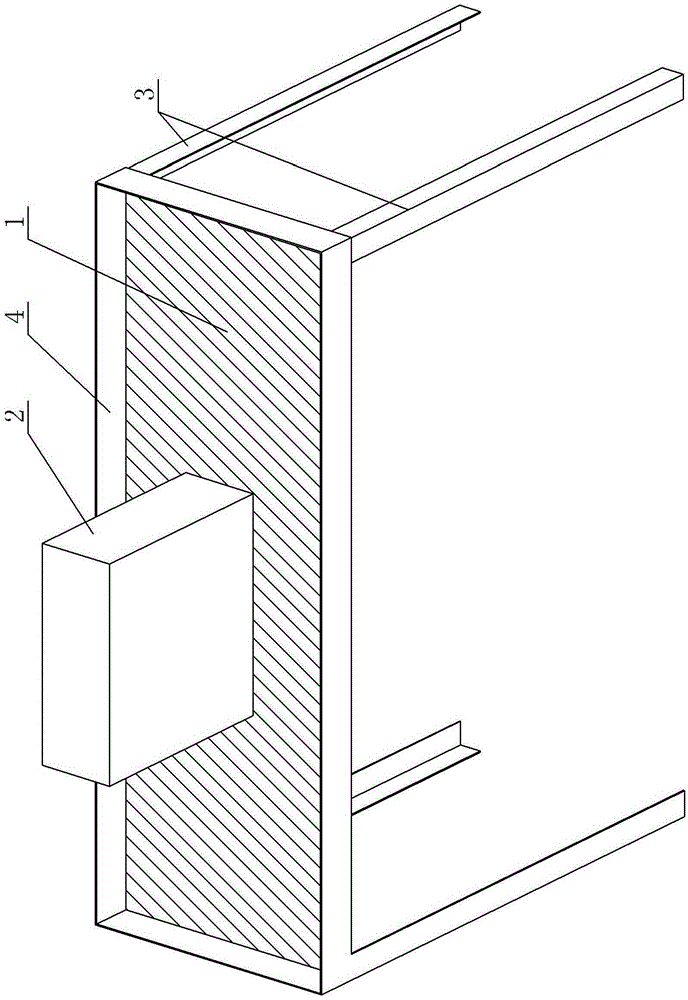

[0012] A bending machine table, see figure 1 : It includes a table top 1 and a bending machine 2, the bottom of the bending machine 2 is supported on the upper surface of the table 1, the table 1 is supported on the upper parallel support point formed by a combination of several columns 3, and the outer periphery of the table 1 is raised to form a guardrail 4.

[0013] Specifically, there are four columns 3, the table top 1 is a rectangular table top, and a column 3 is respectively arranged at the four corners of the table top 1, and the lower end surfaces of the four corners of the table top 1 are respectively supported on the upper ends of the column 3 at the corresponding position;

[0014] The column 3 is specifically an angle iron, and its cross section is an L-shaped structure, and the upper end of each column 3 is respectively welded to the corresponding position of the lower end of the table top 1;

[0015] The height dimension of the guardrail 4 is greater than the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com