Bicycle rim with brake track

A technology for brake rails and bicycles, applied to bicycles, wheels made of non-metallic materials, bicycle accessories, etc., can solve problems such as fragile, damaged rims, and imperfect braking surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention will be described herein with reference to the accompanying drawings. It should be understood that the drawings and descriptions referred to herein are provided for illustration only and not as limitations of the invention as defined by the appended claims and any and all equivalents thereof.

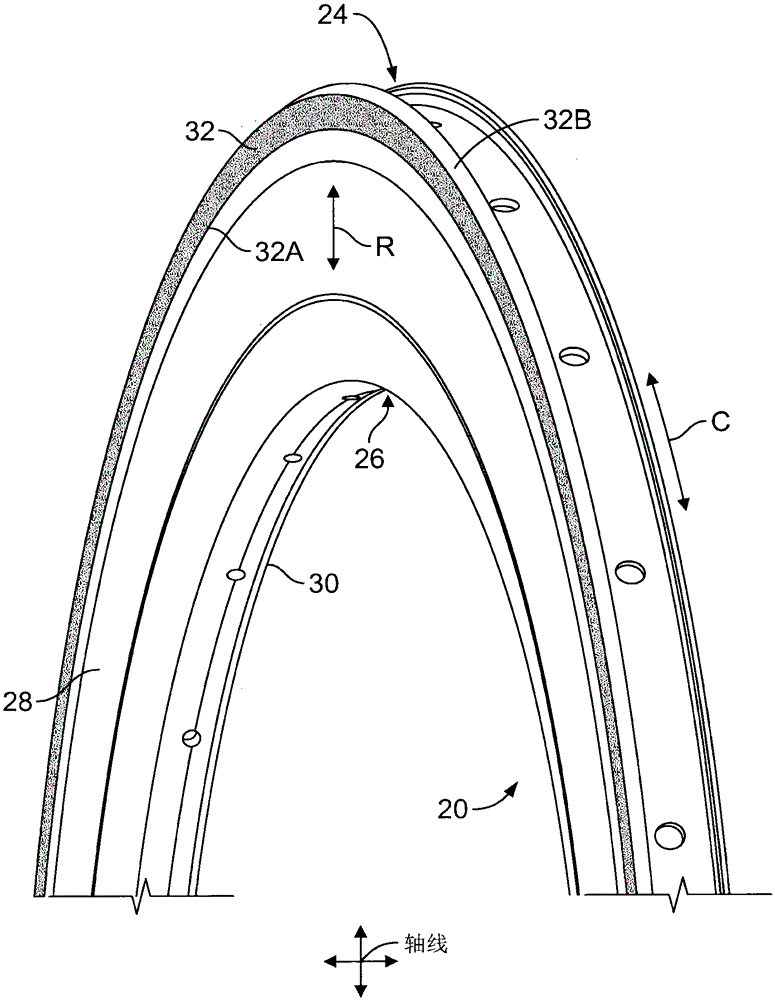

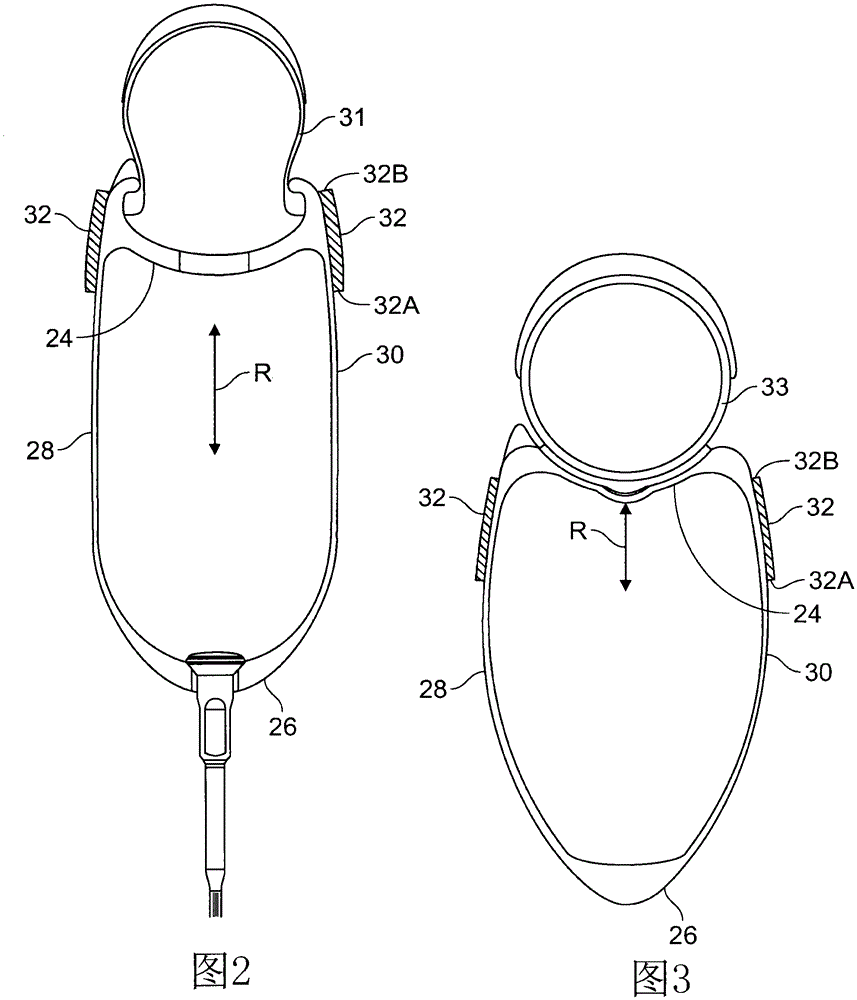

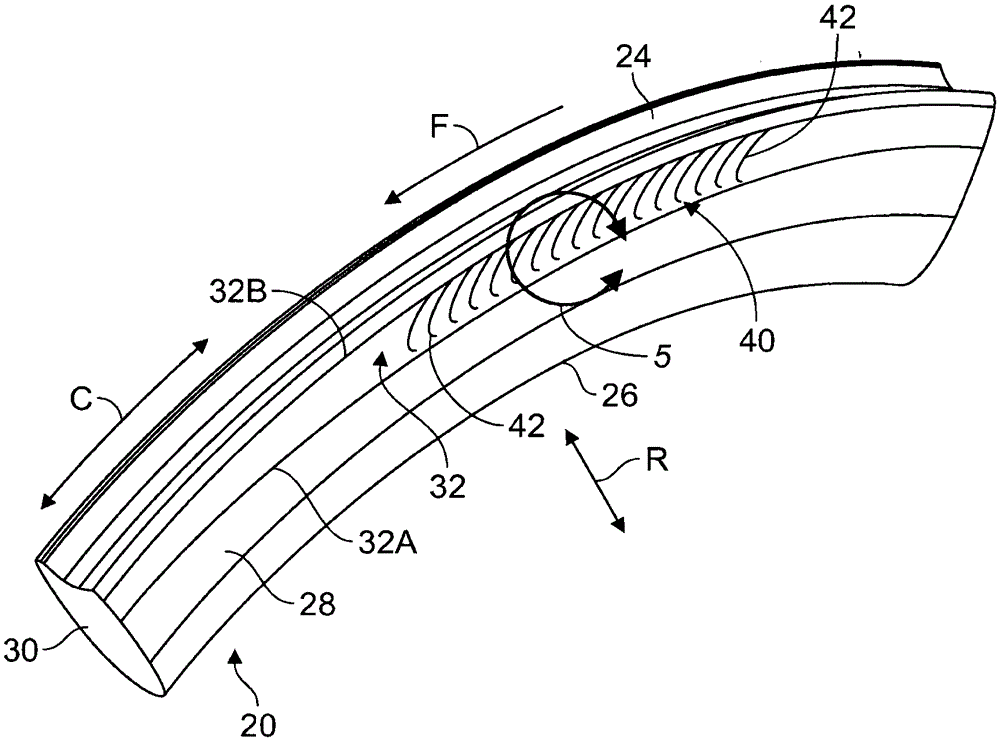

[0027] figure 1 A wheel rim 20 is shown having a brake rail generally indicated at 32 . The rim 20 generally includes a radially outer tire engaging portion 24, a radially inner spoke engaging portion 26, and a first sidewall 28 and a second sidewall 30 spaced from the first sidewall. The first sidewall 28 and the second sidewall 30 may generally extend radially between the tire engaging portion 24 and the spoke engaging portion 26 to form the shape of the rim 20 or a portion thereof. It should be understood that any rim shape including portions that can serve as brake rail 32 is contemplated by the present invention.

[0028] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com