Mobile scaffolding brake

a brake and mobile technology, applied in the field of mobile scaffolding, can solve the problems of prior art brakes that cannot be activated by workers, scaffolding to roll undesiredly, and problems such as the inability of workers to activate prior art brakes,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

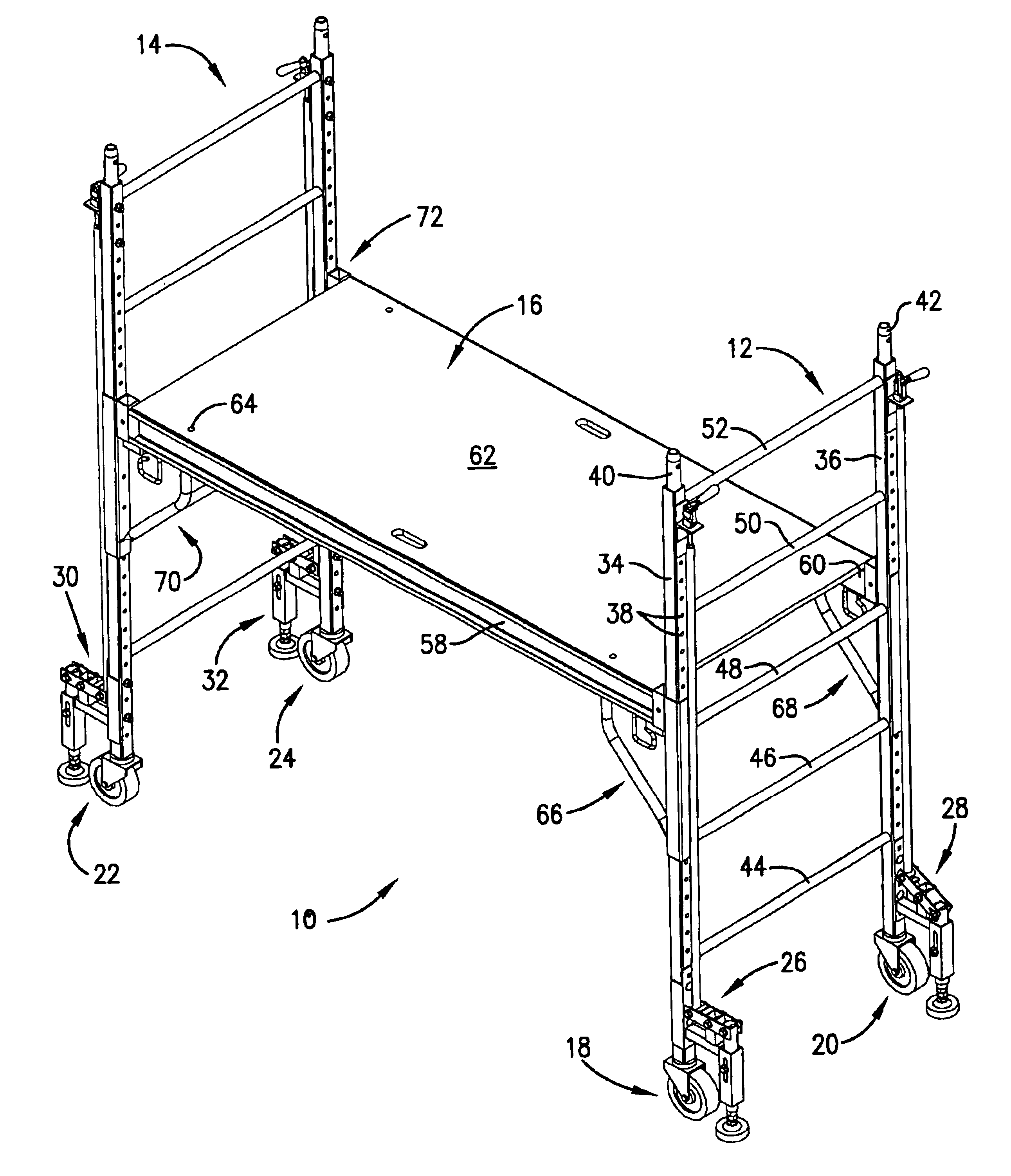

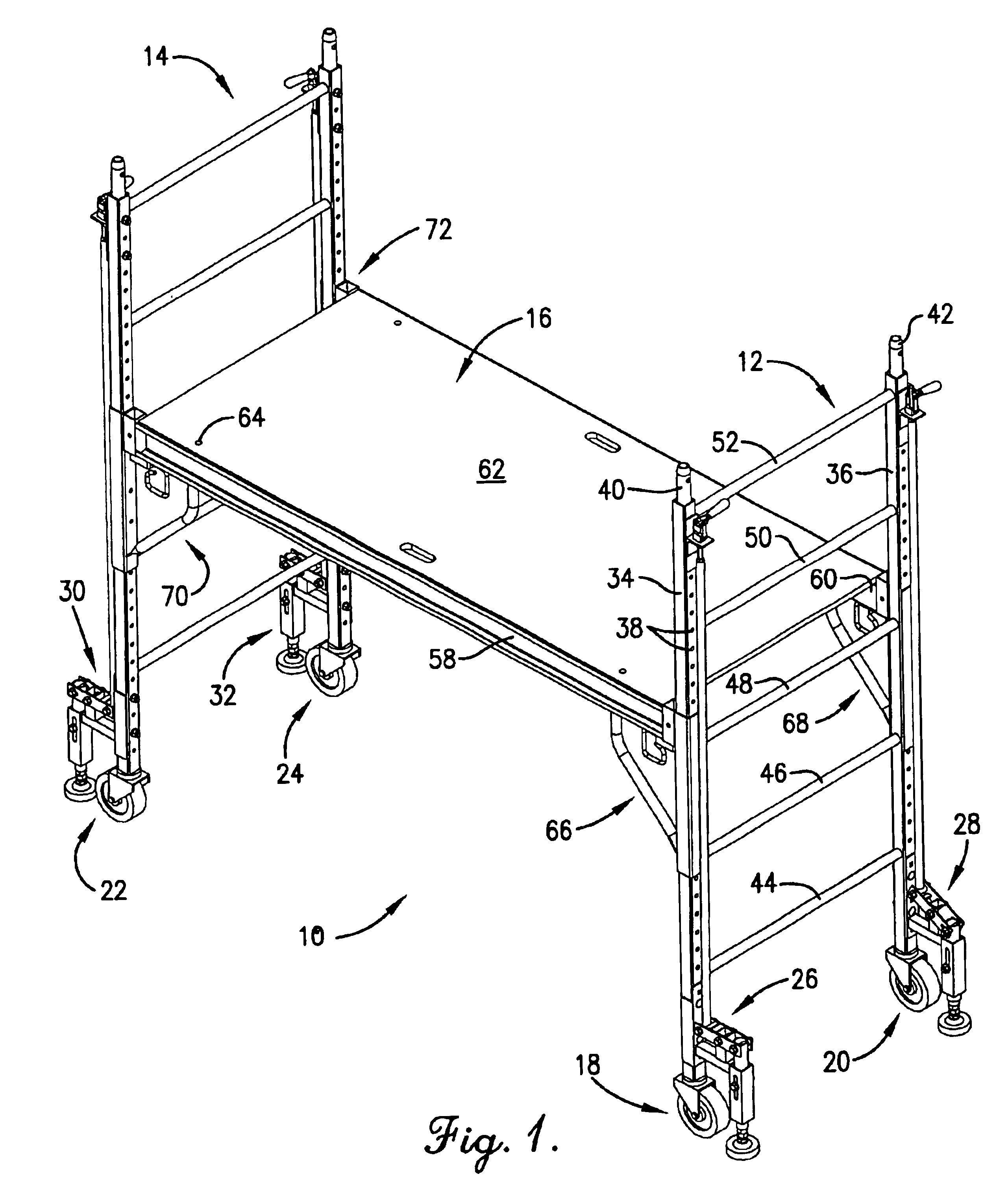

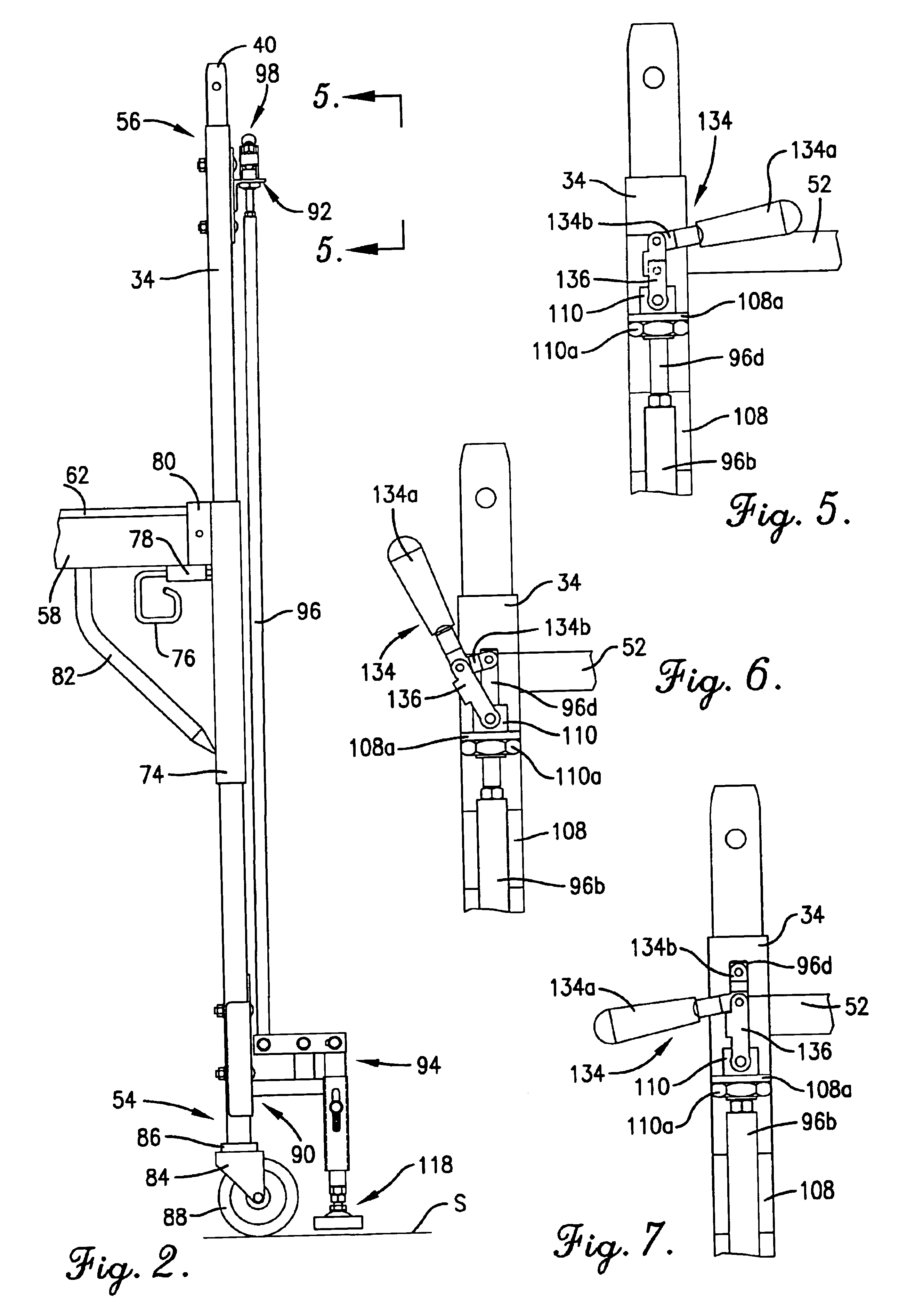

FIG. 1 illustrates a mobile scaffolding 10 constructed in accordance with a preferred embodiment of the present invention and configured for elevating a worker (not shown) above a floor or ground surface S (see FIGS. 2-4). The illustrated scaffolding 10 utilizes a pair of rollable ladder-type frames to support a vertically-adjustable platform therebetween. However, the principles of the present invention are not limited to this scaffolding configuration and equally apply to virtually any type of scaffolding so long as the scaffolding supports an elevated worker and is movable (e.g., rollable, etc.). The illustrated scaffolding 10 broadly includes a pair of frames 12 and 14, a platform 16 supported by the frames 12,14, a pair of casters 18, 20 and 22, 24 rollably supporting a respective one of the frames 12,14, and a brake assembly 26, 28, 30, and 32 associated with a corresponding one of the casters 18,20,22,24, respectively.

In more detail, each of the frames 12,14 is configured to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com