Full-automatic packer

A fully automatic, rack-mounted technology, applied in packaging, wrapping objects, transportation and packaging, etc., can solve the problems of slow packaging efficiency, prone to deformation, and easily damaged products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

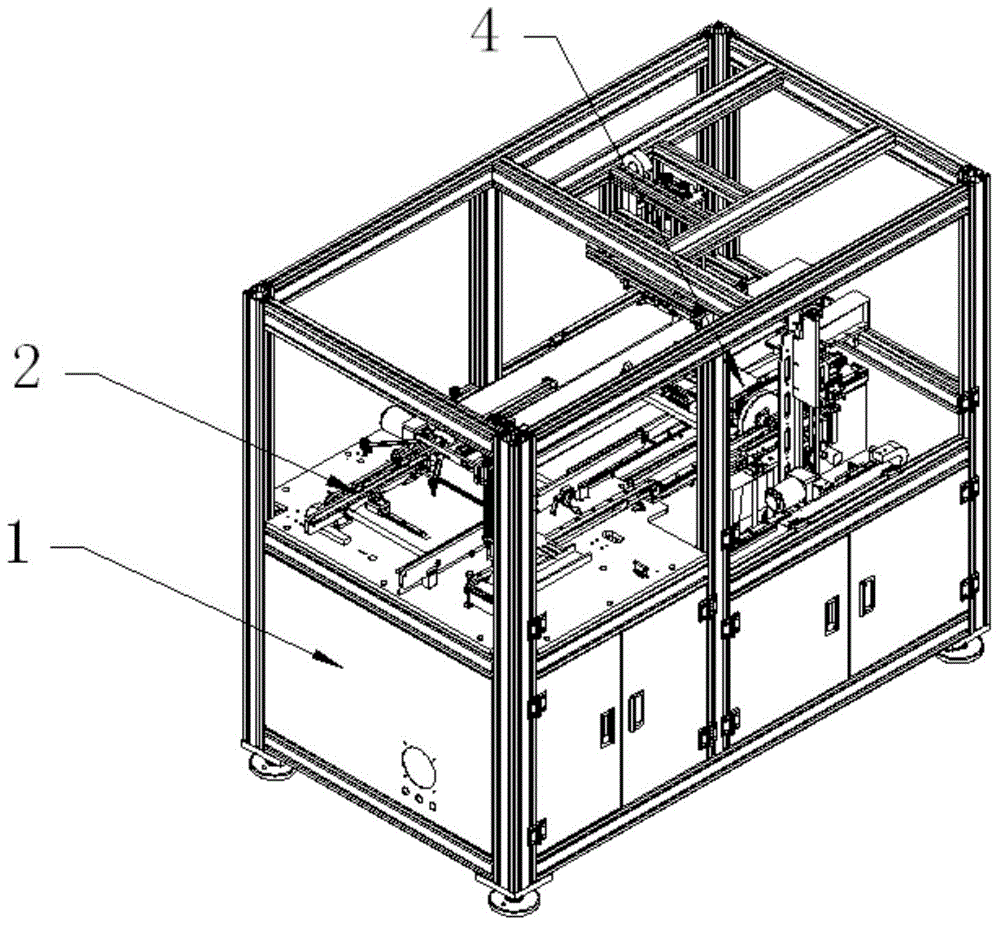

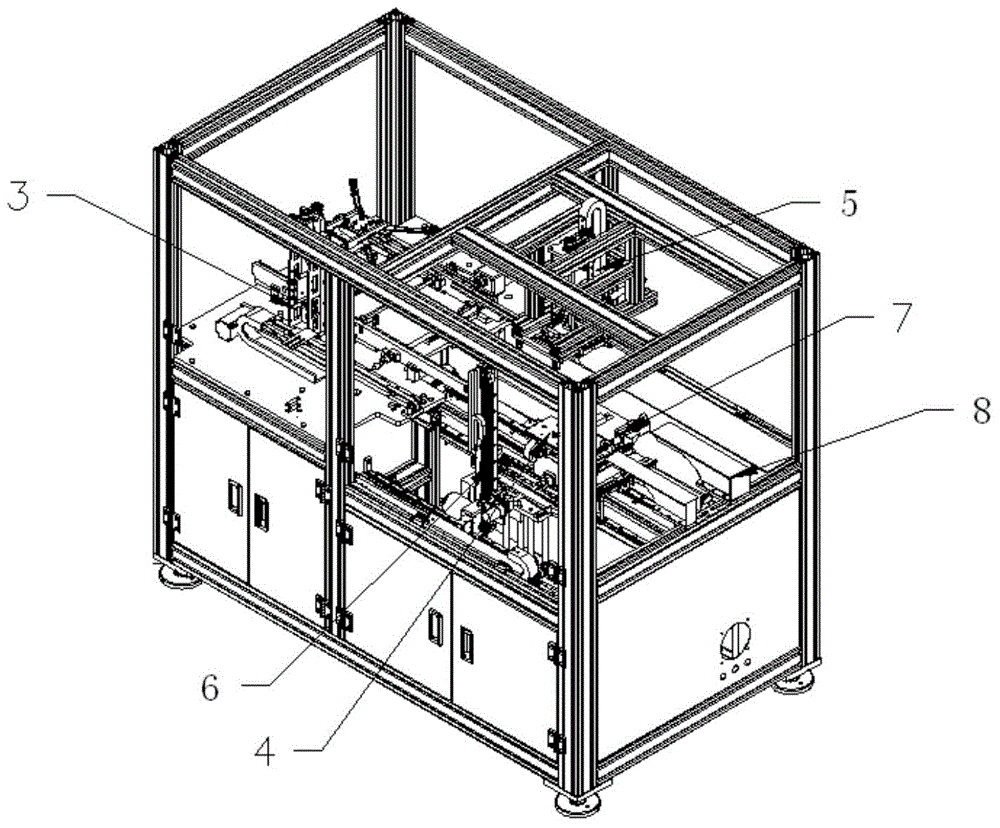

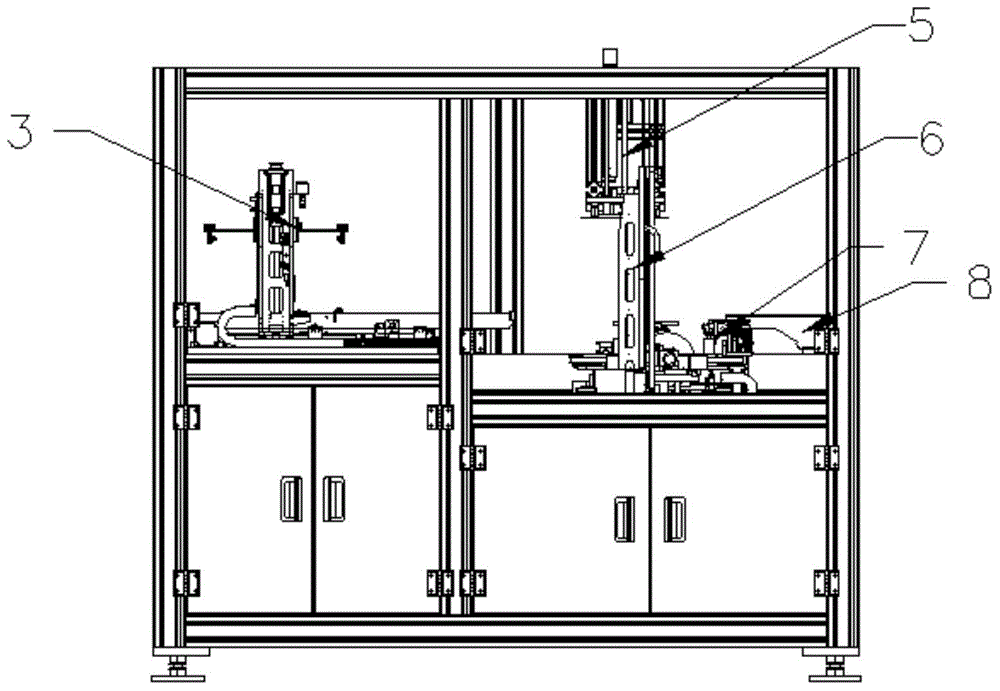

[0047] Embodiment: A fully automatic baler, including a frame 1, a tray conveying module 2, a tray handling module 3, a tray direction sensing device, a tray rotation module 4, a pressing device 5, and a tape winding die Group 6, overall cutting module 7, finished product placement platform 8 and controller, set three mutually perpendicular directions as X direction, Y direction and Z direction, wherein Z direction is the vertical direction;

[0048] The tray conveying module 2 is positioned on the surface of one end of the frame 1, and the tray conveying module 2 can carry out tray conveying along the X direction. The tray conveying module 2 is provided with a tray position sensing device, and the tray position sensing device can Sensing the position of the loading tray of the tray conveying module 2 and sending a signal to the controller;

[0049] The tray rotating module 4 is positioned on the frame 1, and it is located at the front end of the tray conveying module 2 along it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com