Wear-resistant lifter sliding table

A lift and wear-resistant technology, applied in the field of vehicle lifts, can solve the problems of sliding block wear and large friction, and achieve the effects of extending service life, reducing friction and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solution and advantages of the present invention more clear, the following will be further described in detail in conjunction with the accompanying drawings and embodiments.

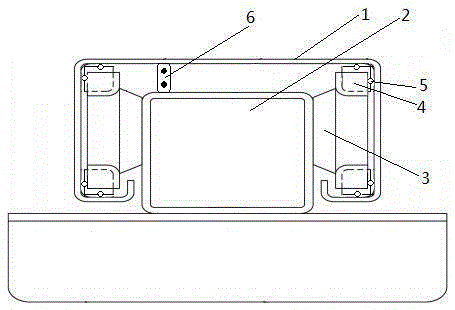

[0026] see figure 1 , figure 1 It is a top view of a wear-resistant lift slide. A wear-resistant lift slide according to the present invention comprises:

[0027] A column 1, which is a three-sided square hollow cylinder, is vertically arranged on the ground;

[0028] A sliding platform 2 is a square block, and the sliding platform 2 is embedded in the column 1, and the sliding platform 2 is not in direct contact with the column 1;

[0029] Two slider brackets 3 are trapezoidal, and the slider brackets 3 are fixed in the middle of the two sides of the slide table by screws;

[0030] Four sliders 4 are square blocks, which are respectively arranged at the four corners of the column 1, and the outer corners of the slider 4 and the slider bracket 3 are fixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com