Methyl-phenyl-piperazinyl modified polysiloxane

A technology of methylphenyldimethoxysilane and polysiloxane, which is applied in the field of synthesis of methyl-phenyl-piperazinyl modified polysiloxane, can solve the problem of increased stability and hydrophilicity, Unsatisfactory hydrophilicity, unsatisfactory temperature change adaptability, etc., to achieve the effect of easy emulsification and improved storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Hydrolysis of methylphenyldimethoxysilane

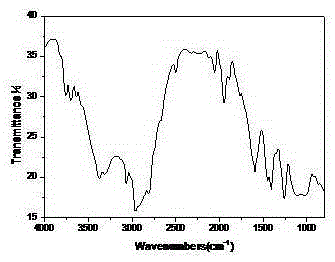

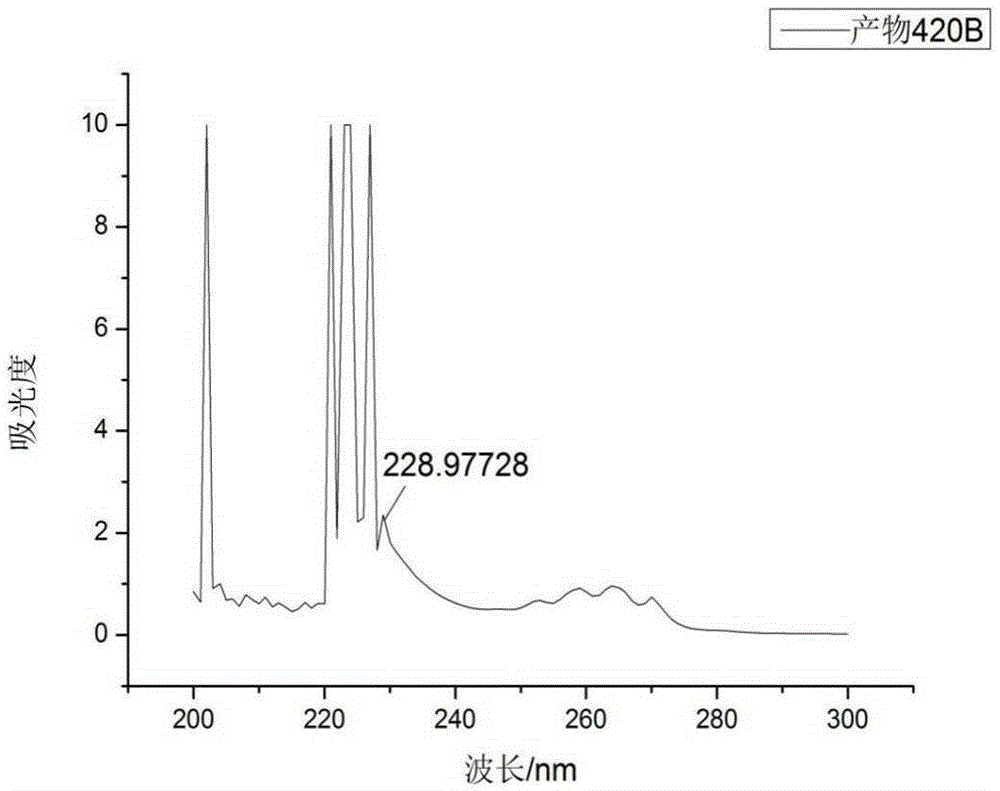

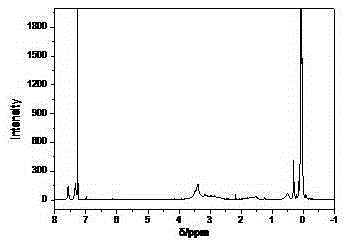

[0024] with N 2 Add 18.22g of methylphenyldimethoxysilane into the three-necked flask of the protective device, raise the temperature to 80°C, add 3.8g of deionized water dropwise into the flask, and continue the reaction for 1h. The two separated items gradually react. Eventually a homogeneous liquid is formed. Remove N 2 Protect the device, vacuumize for 2 hours, and finally obtain a light yellow transparent liquid, which is a hydrolyzate.

Embodiment 2

[0025] Example 2: Preparation of methyl-phenyl-piperazinyl modified polysiloxane

[0026] with N 2 Add 6.1g of octamethylcyclotetrasiloxane, 1.2g of the hydrolyzate in Example 1, 0.36g of 10% KOH to the flask of the protective device, react at a constant temperature of 50°C for 2h, and then add 3g of γ-piperazinylpropylmethyl dimethyl Oxysilane, continue to react for 1h, add 1g of hexamethyldisiloxane, react for 40min, add glacial acetic acid to neutralize the system, remove low boilers under reduced pressure, and obtain methyl-phenyl-piperazinyl with a viscosity of 111cp Modified polysiloxane.

Embodiment 3

[0027] Example 3: Preparation of methyl-phenyl-piperazinyl modified polysiloxane

[0028] with N 2 Add 6.5g of octamethylcyclotetrasiloxane, 1.0g of the hydrolyzate in Example 1, 0.36g of 10% KOH to the flask of the protective device, react at a constant temperature of 60°C for 2h, and then add 3g of γ-piperazinylpropylmethyl dimethyl Oxysilane, continue to react for 1h, add 1g of hexamethyldisiloxane, react for 40min, add glacial acetic acid to the system to neutralize, remove low boilers under reduced pressure, and obtain methyl-phenyl-piperazine with a viscosity of 488cp Modified polysiloxane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com