Downhole Fault Prediction Method of Rod Pumped Oil Well Based on Multivariable Gray Model

A gray model and fault prediction technology, applied in construction and other fields, can solve problems such as complex working conditions, high fault incidence, and affecting normal production of oil fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

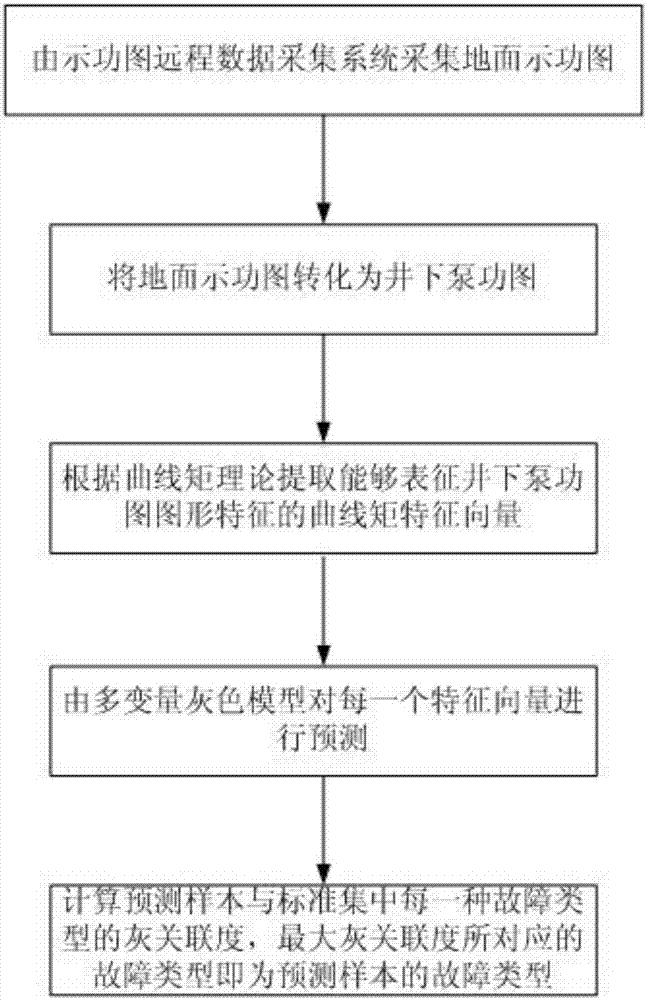

[0127] A downhole fault prediction method for rod pumped oil wells based on a multivariable gray model, the steps of which are as follows:

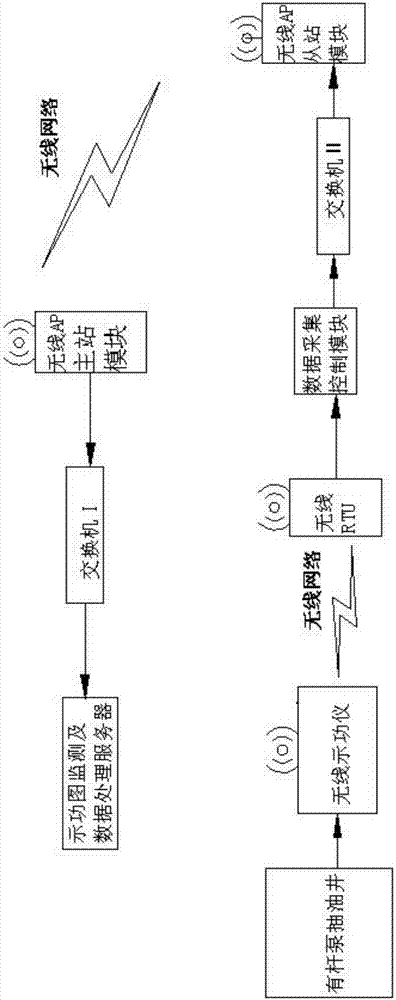

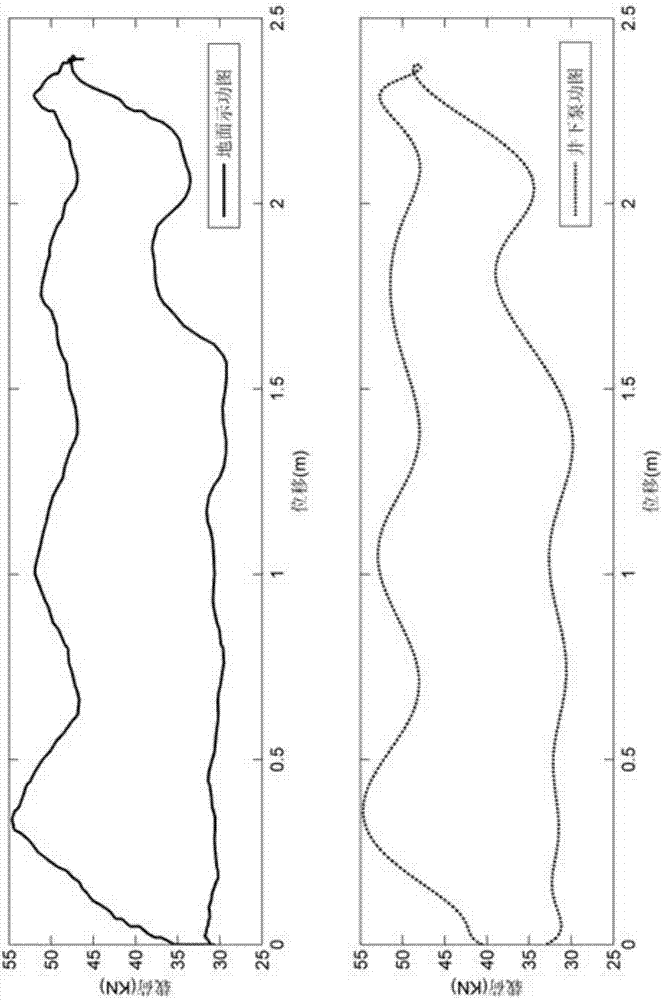

[0128] 1. If figure 1 and figure 2As shown, using the remote data acquisition system of the dynamometer diagram, firstly, the wireless dynamometer is installed on the donkey head of the pumping unit of the rod pump well, and the load and displacement data of the polished rod are collected; the wireless RTU receives the wireless data in a wireless way. The data collected by the dynamometer is remotely transmitted to the wireless AP master station module by the data acquisition module through the switch 2 through the wireless AP slave module through the wireless network, and then transmitted to the dynamometer graph monitoring and data processing server through the switch 1; The map monitoring and data processing server receives the collected load and displacement data of the polished rod, and draws the collected ground dynamometer graph....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com