Recognition and simulation numbering method and equipment for plastic packaging equipment based on visual equipment transformation

A kind of equipment and numbering technology, which is applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of excessive mold use times, affecting product quality, mismatching of upper and lower molds, etc., and achieve product yield , reduce product scrap rate, and reduce communication costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following describes in detail the identification and numbering method of plastic packaging equipment based on visual equipment transformation involved in the present invention with reference to the accompanying drawings and embodiments.

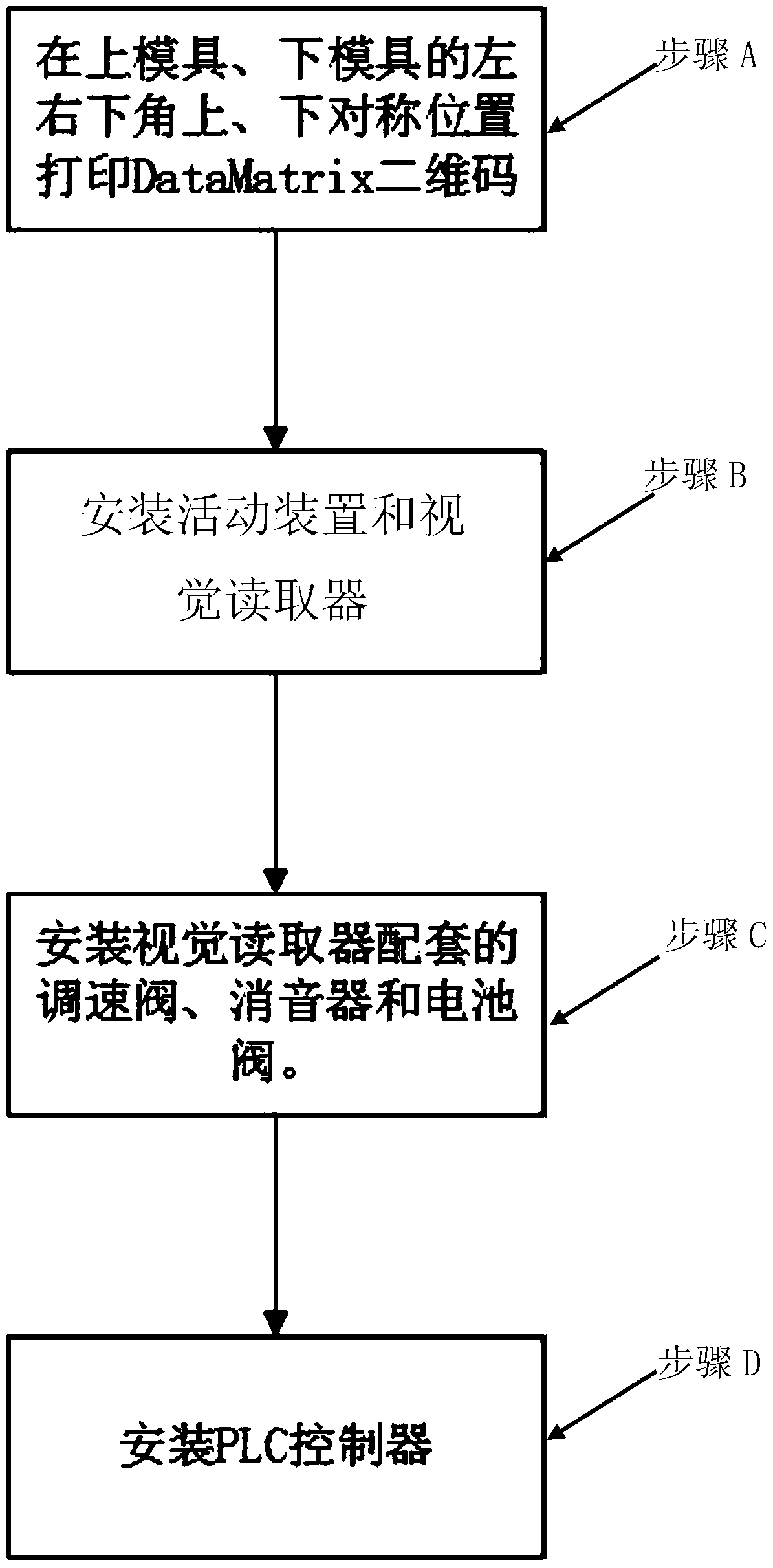

[0023] figure 1 It is a flow chart of the method for identifying analog numbering of plastic packaging equipment based on visual equipment transformation in an embodiment of the present invention.

[0024] Such as figure 1 As shown, the reconstruction of plastic-encapsulated equipment identification simulation numbering method based on visual equipment has the following steps:

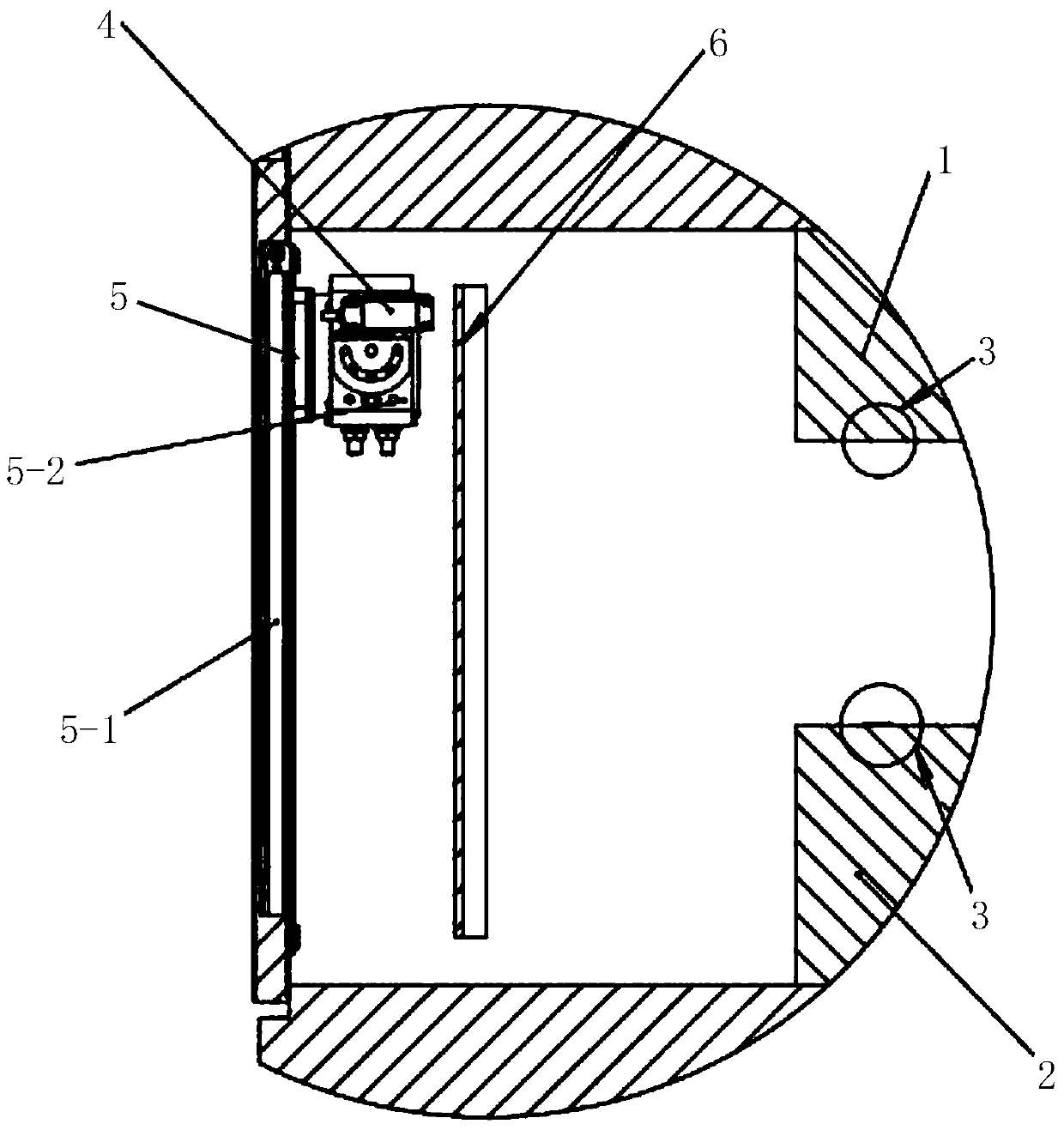

[0025] Step A: Print the DataMatrix QR code 3 on the upper side of the upper mold 1 and the lower side of the lower mold 2 at symmetrical positions. The size of the DataMatrix QR code 3 is: 8*8mm. Do not print the position of the DataMatrix QR code 3 on the middle CavityBar. The content of the DataMatrix QR code 3 is the number of the upper mold 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com