LED bracket and production method thereof

A technology of LED bracket and insulating body, applied in the field of LED bracket, can solve problems such as poor appearance, and achieve the effect of avoiding glue overflow and solving poor appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

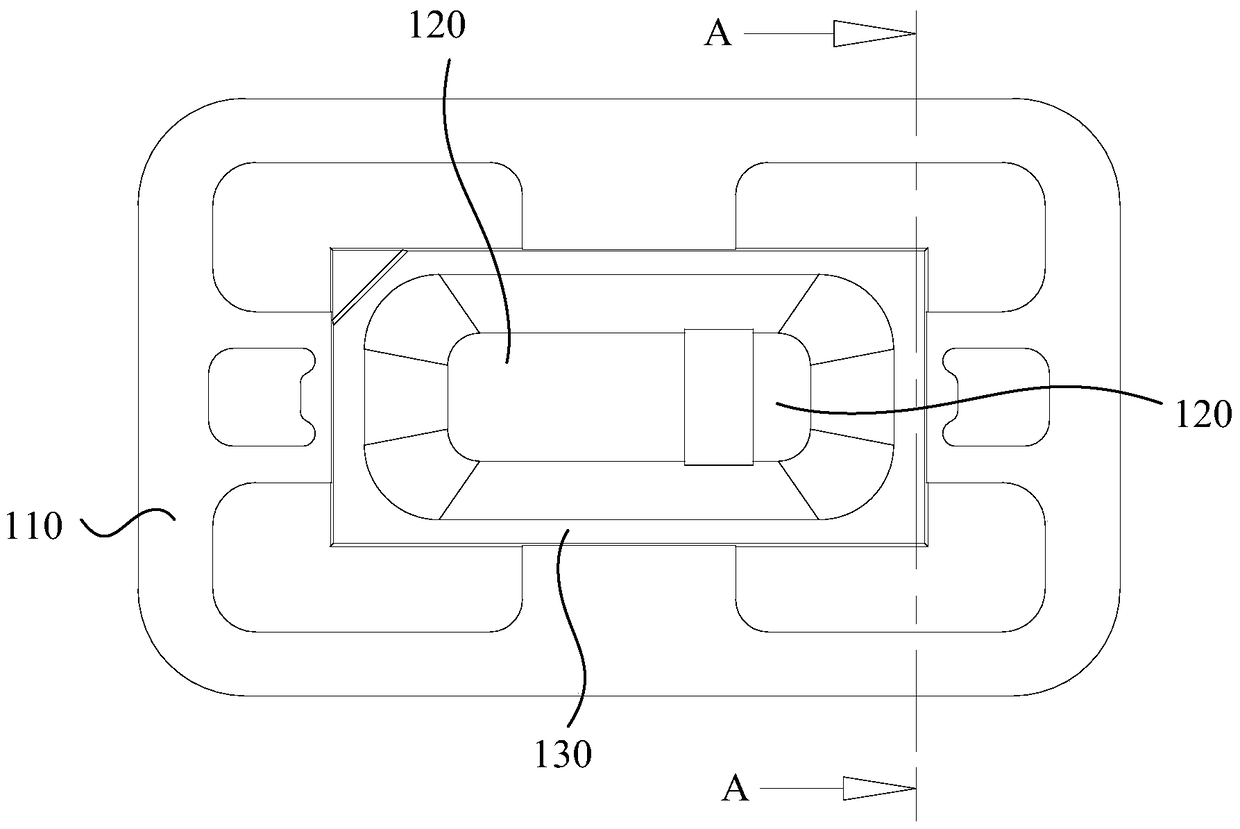

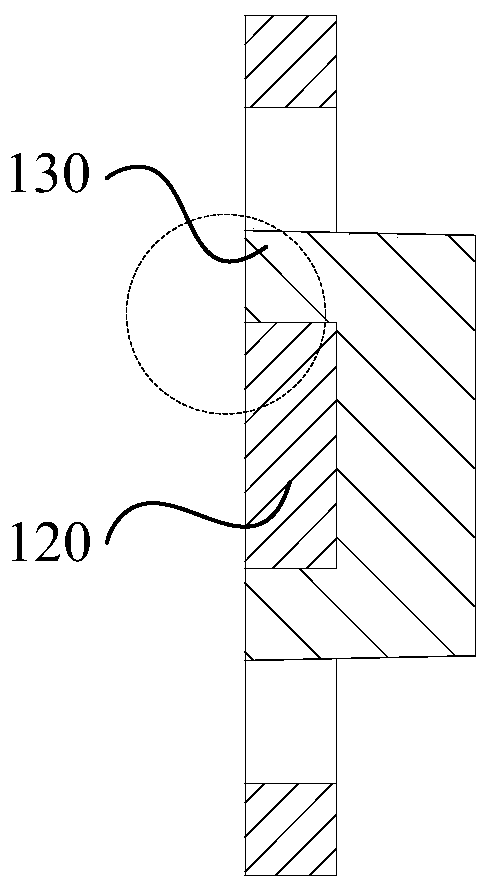

[0026] Such as Figure 4 and Figure 5 As shown, the LED bracket provided by the present invention includes an insulating body 230 and at least one pair of conductive terminals 220 combined with the insulating body 230 . Specifically, in this embodiment, the conductive terminals 220 are a pair. It can be understood that in other embodiments, the number of the conductive terminals 220 can be adjusted according to different needs. The conductive terminal 220 serves as the carrier of the LED chip and is electrically connected to the LED chip at the same time. The conductive terminal 220 is then connected to an external power source, so that the LED chip can emit light and work normally.

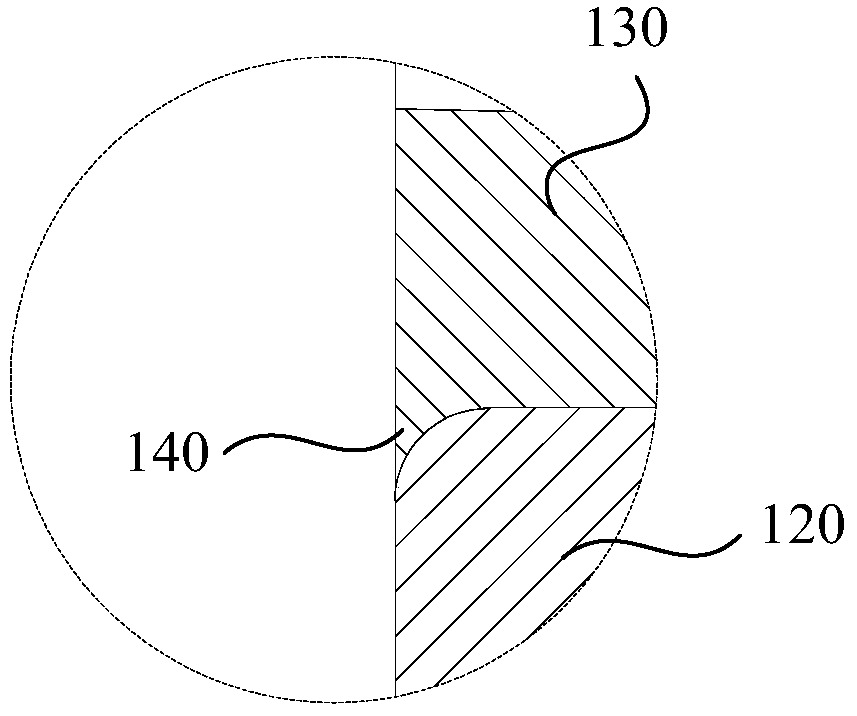

[0027] The insulating body 230 is generally combined with the conductive terminal 220 by injection molding to form an integral structure. Also refer to Figure 6 , the conductive terminal 220 has a bonding surface 223 that is punched and combined with the insulating body 230 and a non-bonding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com