Multiple corner wheel sets at different installation positions of automatic feeding system of livestock farm

A technology of feeding system and installation location, applied in animal feeding devices, applications, animal husbandry, etc., can solve the problems of unreasonable structure design of corner wheel set, short maintenance period, and inability to transport feed away.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] To facilitate the understanding of those skilled in the art, the present invention will be described in detail below in conjunction with the drawings and specific embodiments.

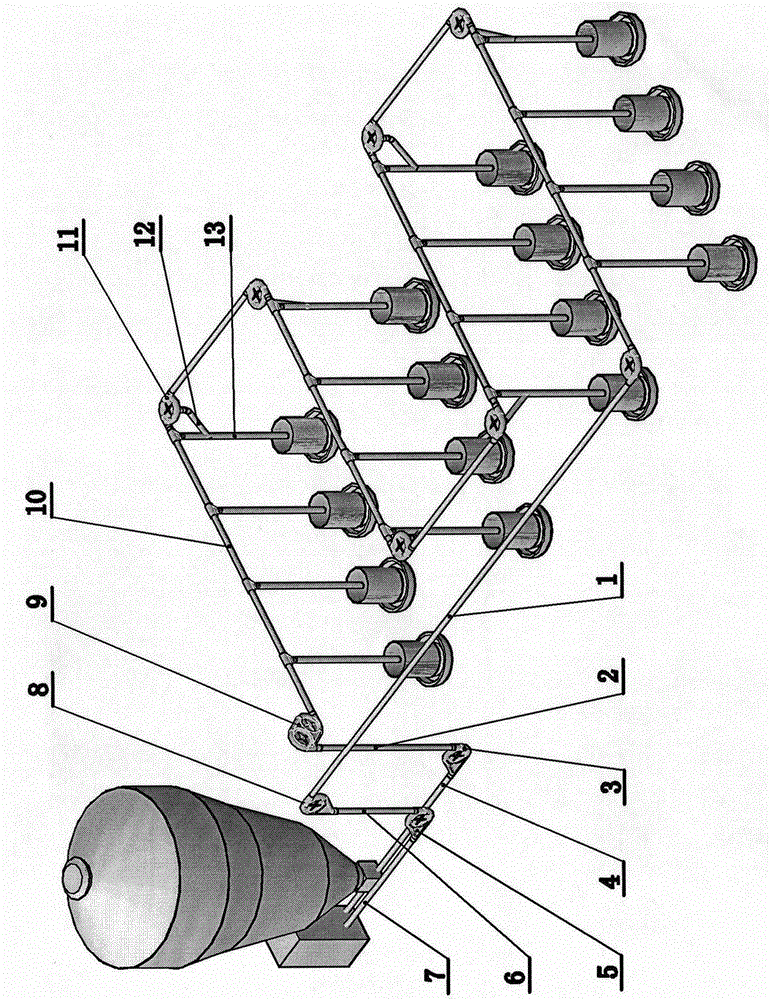

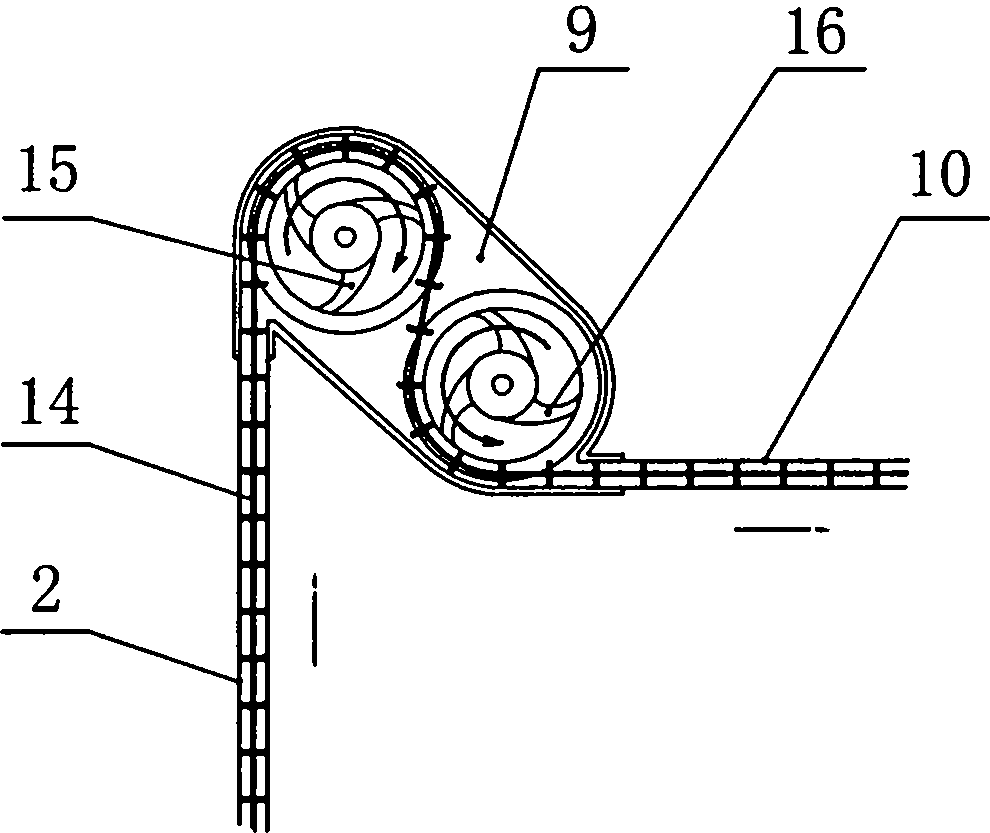

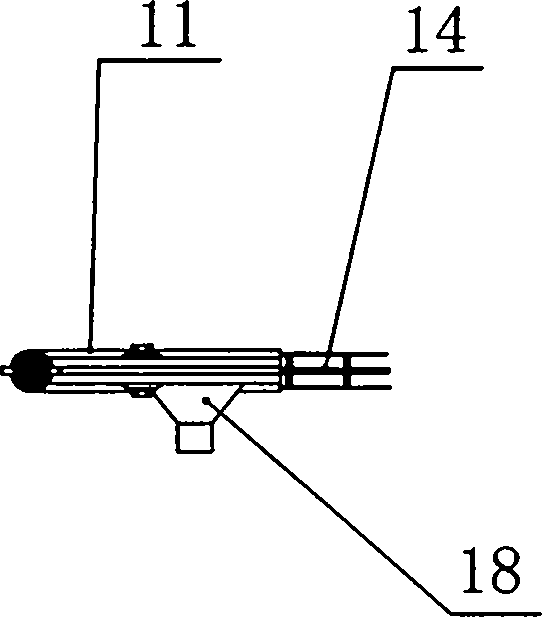

[0015] Such as Figure 1-Figure 5 As shown, a variety of corner wheel sets used in different installation positions in the automatic feeding system of the farm, including vertical to horizontal transport corner wheel sets, horizontal transport corner wheel sets, and horizontal to vertical corner wheel sets. The described vertical-to-horizontal conveying corner wheel set includes a housing 9, a high-position rotating wheel 15, and a low-position rotating wheel 16. The described housing 9 is composed of two parts, which are connected as a whole by screws. The housing 9 and the The bottom surface adjacent to the material inlet is set as an inclined surface, which is convenient for fast blanking. The high-position rotary wheel 15 and the low-position rotary wheel 16 are installed in the housing 9, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com