Internal structure of wheel housing

A technology for wheel covers and structures, applied to superstructures, superstructure subassemblies, vehicle parts, etc., can solve problems such as differences, and achieve the effect of ensuring rigidity and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

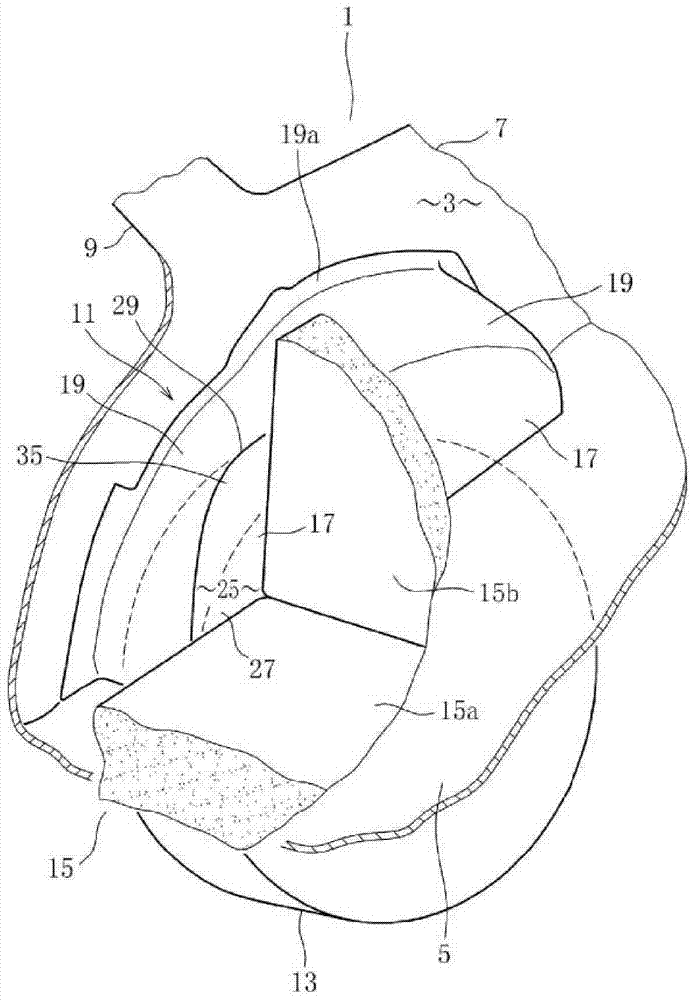

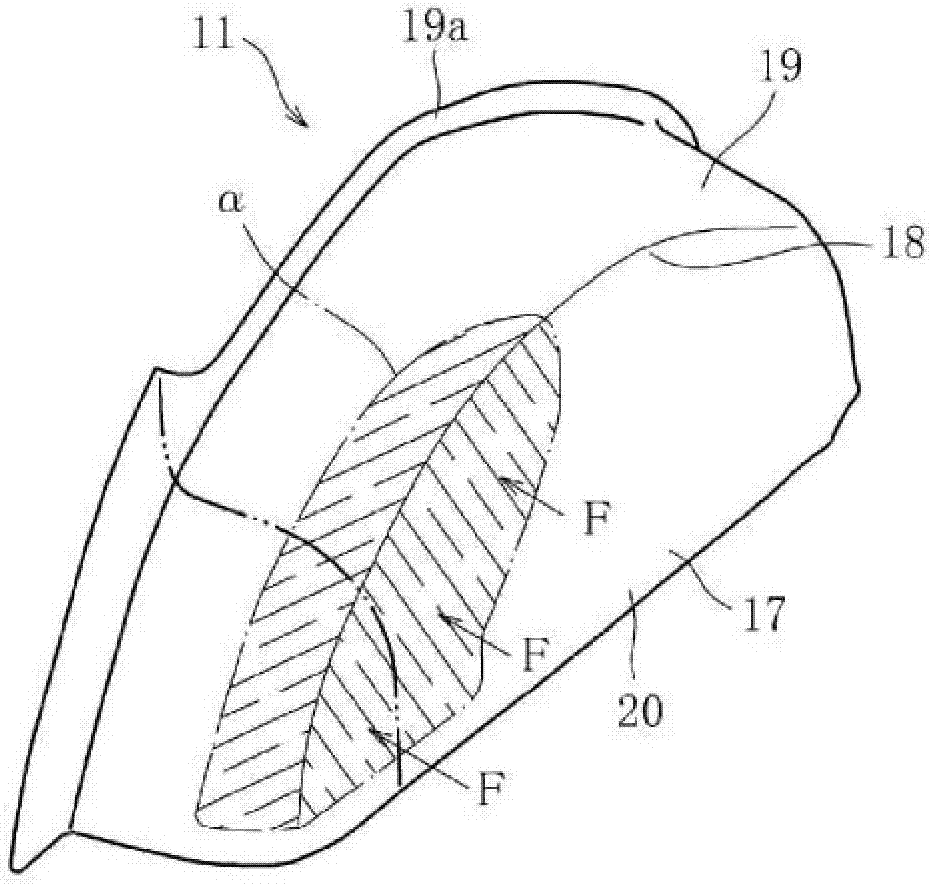

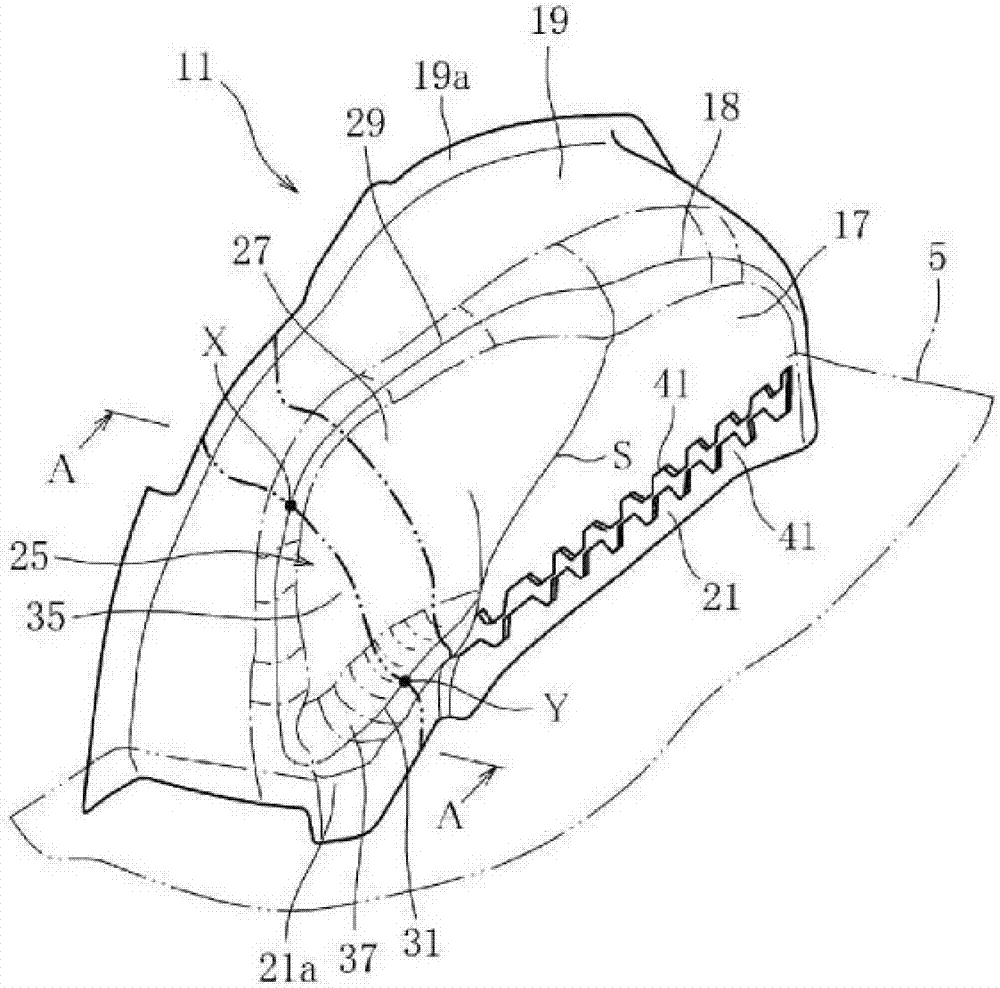

[0036] In the following, according to the Figure 1 to Figure 4 The embodiments shown in , describe the invention.

[0037] figure 1 The rear side of a vehicle (for example, a van) to which the invention is applied is shown.

[0038] Referring to the main structure of the truck, in figure 1 The number 1 in the figure is the body of the truck (vehicle), the number 3 is the interior of the compartment formed inside the body 1, the number 5 is the floor for forming the rear floor of the interior 3 of the compartment, and the number 7 is the floor for forming the body The rear quarter inner panel of the inner wall of the compartment of 1, and numeral 9 is the rear pillar inner panel (element for forming the rear panel) formed on the upper part of the rear quarter inner panel 7. The lower part of the rear quarter inner panel 7 has a rear wheel house inner part 11 (wheel house inner part). The rear tire 13 is accommodated inside this rear wheelhouse inner part 11 . Furthermore,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com