Automatic strapping machine pressure material support material adjustment mechanism

A technology of automatic strapping and adjusting mechanism, which is applied to the parts of strapping machinery, strapping objects, packaging/bundling objects, etc., can solve the problems of complex structure, increased labor time cost, difficult gap width, etc., and achieves a simple overall structure, The effect of saving manual adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

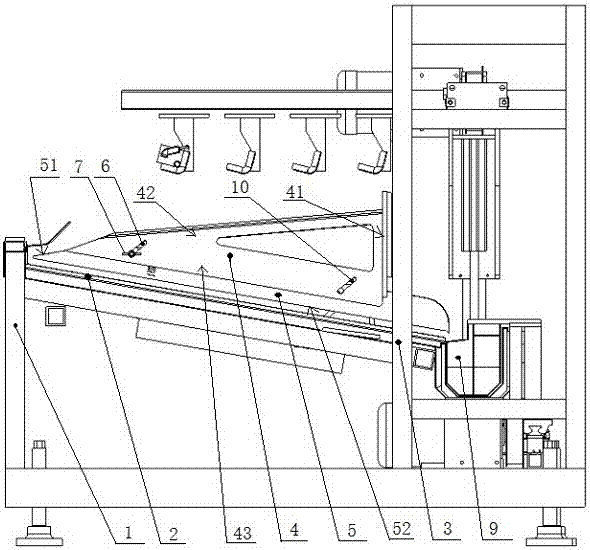

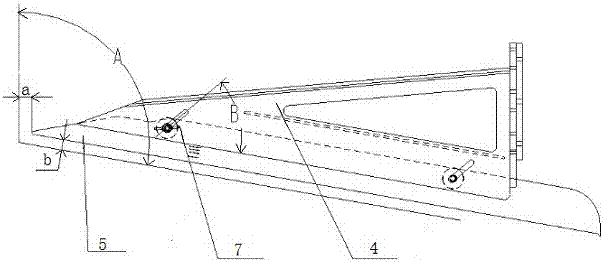

[0022] Such as Figure 1 to Figure 4 As shown, a kind of automatic strapping machine pressure material support material adjustment mechanism is used to adjust and guide the pipe to roll into the strapping packaging station 9, including a support frame, which includes a first support vertical part 1, a second Supporting the vertical part 3 and the supporting inclined part 2 fixed between them, an obtuse angle is formed between the first supporting vertical part 1 and the supporting inclined part 2, so that the pipe can roll obliquely on the supporting inclined part 2 Falling to the bundling and packaging station 9, a fixed jacket 4 is provided above the supporting inclined part 2 for guiding the inclined rolling of the pipe. The material plate 5 is provided with two inclined grooves on the fixed jacket 4, which are respectively the first inclined groove 6 and the second inclined groove 10, and the included angle formed between the two inclined grooves and the supporting incline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com