Method for putting in and taking out coiled tubing being used as production tubing string

A technology for producing pipe strings and tubing, which is applied in earth-moving drilling, wellbore/well components, etc., can solve the problems of unusable main valve 1, unreliable pipe string sealing, high risk of loss of sealing, etc. The effect of safety and reliability, reducing construction risks and reducing working time under pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

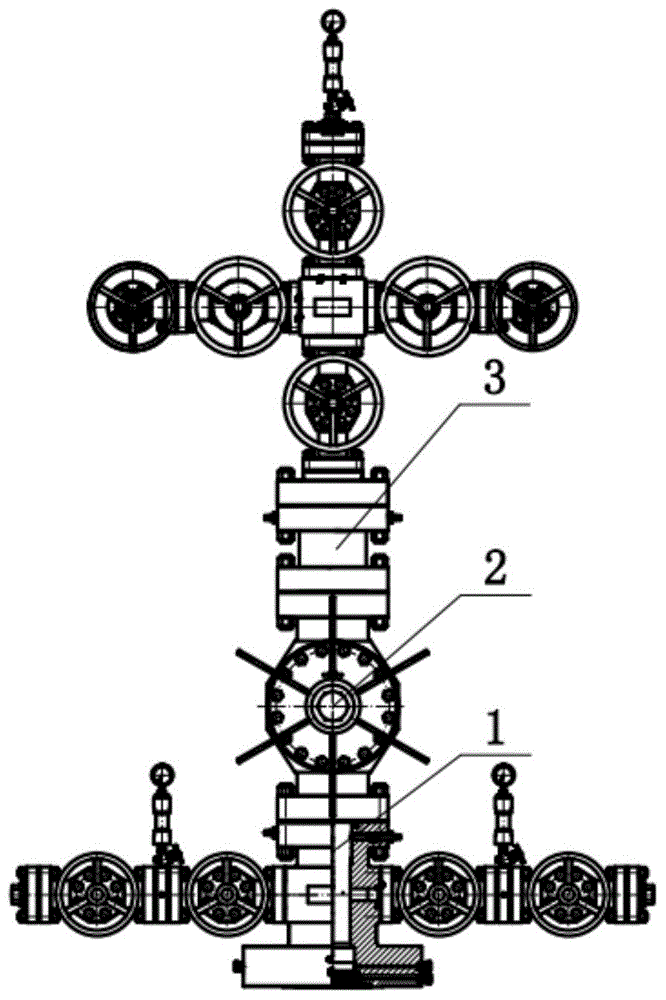

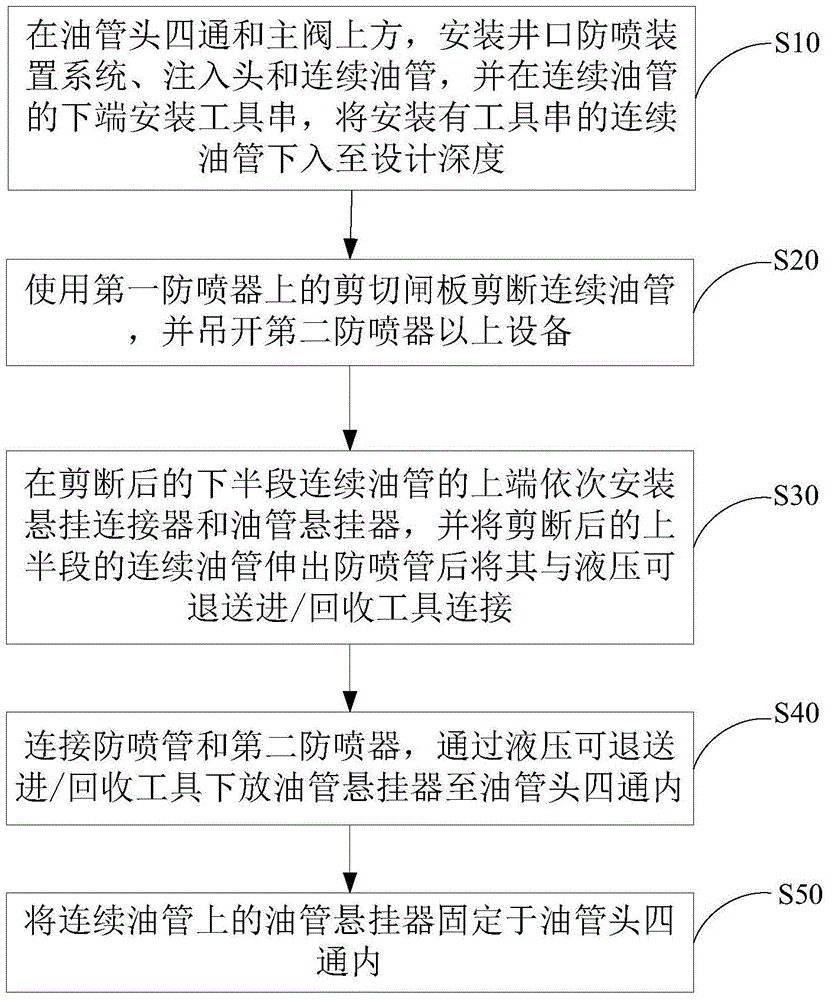

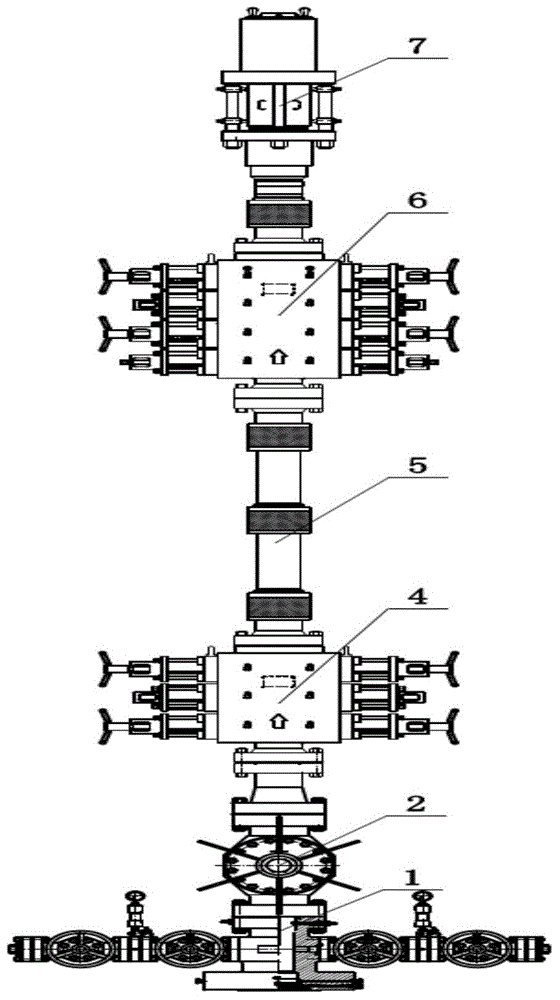

[0048] refer to Figure 2 to Figure 4 , figure 2 It is a schematic flow diagram of running a coiled tubing production string in the method for running in and out of the coiled tubing production string of the present invention; image 3 A schematic diagram of the wellhead structure for the method of running in and out of the coiled tubing production string; Figure 4 It is a structural schematic diagram of a downhole tool string using the method for running in and out of a coiled tubing production string.

[0049] In this preferred embodiment, a method for running in and out of a coiled tubing production string, wherein, when running into a coiled tubing production string, it includes:

[0050] Step S10, above the tubing head spool 1 and the main valve 2, install the wellhead blowout preventer system, injection hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com