Engine speed control structure and control method for rear power take-off

A technology of engine speed and control structure, applied in engine control, machine/engine, electrical control, etc., can solve the problems of potential safety hazards, the inability to limit the maximum engine speed, etc., and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

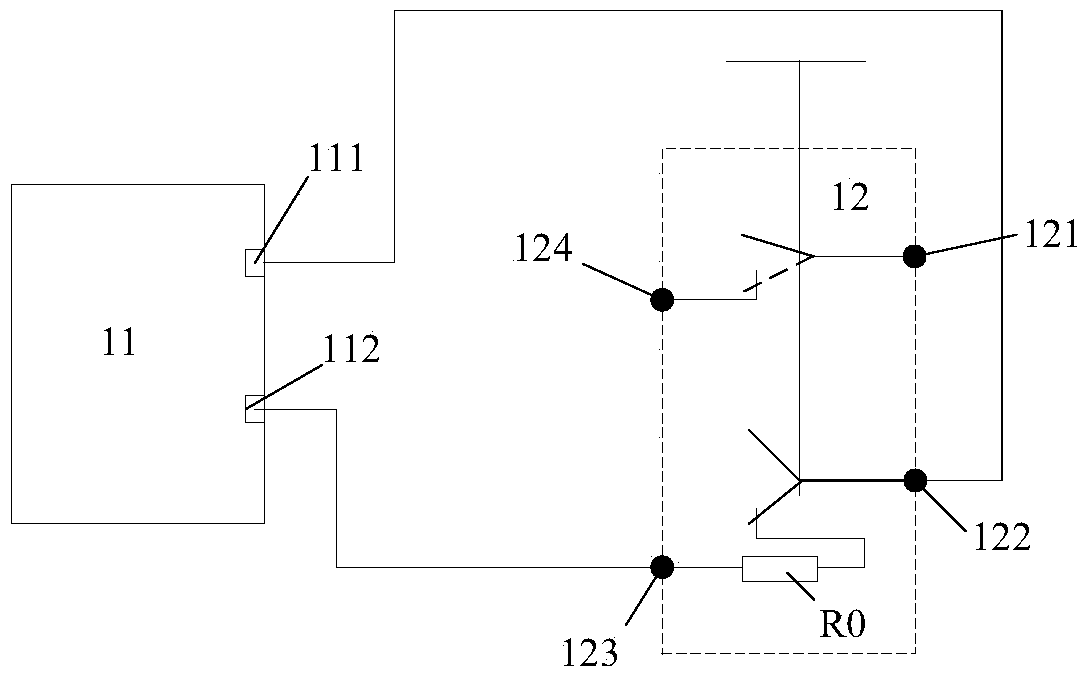

[0043] figure 1 It is a structural schematic diagram of the engine speed control structure at the time of power take-off provided in Embodiment 1 of the present invention. Such as figure 1 As shown, the control structure includes:

[0044] ECU 11 and rear power take-off switch 12, wherein, ECU comprises first interface 111 and second interface 112, and rear power take-off switch 12 comprises first contact 121, second contact 122, third contact 123, fourth contact Point 124 and preset resistor R0;

[0045] The preset resistor R0 is set on the line where the third contact 123 is located;

[0046] The first contact 121 is connected to a power supply ( figure 1 Not shown in ) connection, the power supply can be a storage electric screen that provides 24V voltage.

[0047] The first interface 111 is connected to the second contact 122;

[0048] The fourth contact 124 is used to connect the rear power take-off device ( figure 1 not shown in);

[0049] The second interface 11...

Embodiment 2

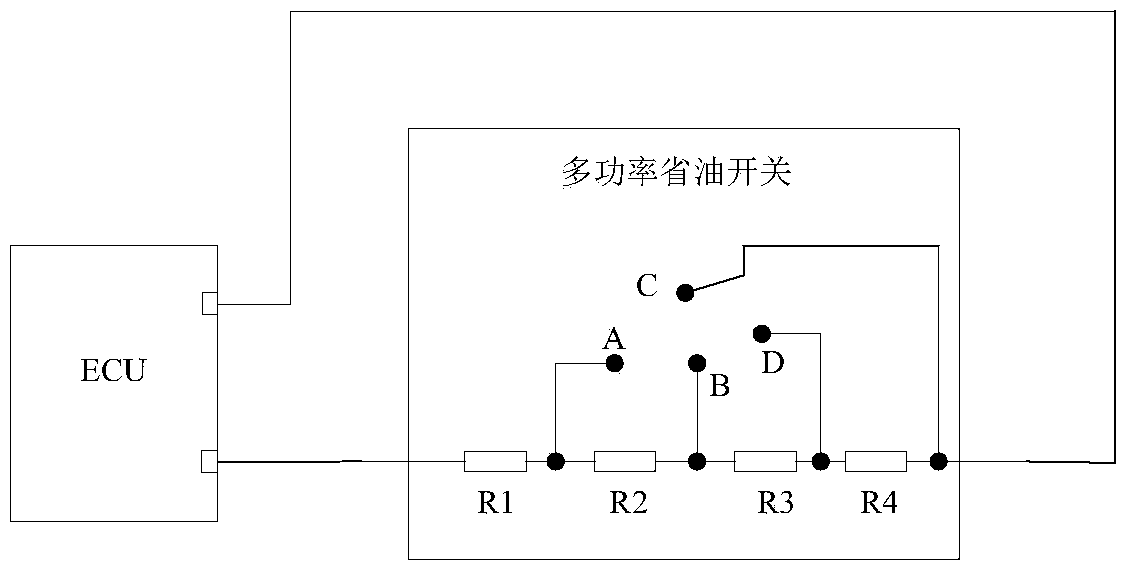

[0069] Figure 4 It is a structural schematic diagram of the engine speed control structure at the time of power take-off provided by Embodiment 2 of the present invention. It should be noted, Figure 4 The shown engine speed control structure at the time of power take-off includes all components of the control structure in Embodiment 1, and the connection relationship of each component is the same as that of the corresponding components in Embodiment 1.

[0070] specifically, Figure 4 The engine speed control structure when the shown rear power take-off includes an ECU 41 and a rear power take-off switch 42, wherein the ECU 41 includes a first interface 411 and a second interface 412, and the rear power take-off switch 42 includes a first contact 421, a second contact The point 422, the third contact 423, the fourth contact 424 and the preset resistor R0'.

[0071] The preset resistor R0' is set on the line where the third contact 423 is located;

[0072] The first conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com