Bolt type sucker

A bolt type, suction cup technology, applied in suction cups, connecting components, mechanical equipment, etc., can solve the problems of no longer adsorption, prone to air leakage, suction cup body leakage, etc., to achieve permanent adsorption, prevent air leakage, Avoid the effect of laxity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

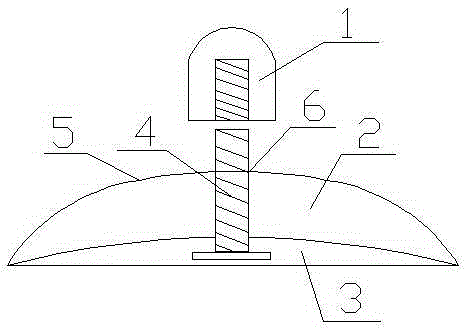

[0013] Such as figure 1 Shown is the structure schematic diagram of the present invention, a kind of bolt-type sucker, comprises flexible sucker body 3, is provided with gland 5 above the sucker body 3, forms a hollow part 2 between the bottom surface of gland 5 and sucker body 3, sucker The middle part of the body 3 is provided with a screw 4, the screw 4 is provided with a compression nut 1, the middle part of the gland 5 is also provided with a through hole 6, the screw 4 passes through the through hole 6 and is arranged in the middle of the suction cup, and the compression nut 1 is arranged in the pressure Cover 5. In the present invention, by setting the compression nut 1 and turning the compression nut 1 duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com