Self-adaptation locking device

A locking device and self-adaptive technology, applied in the direction of brake actuators, etc., can solve the problems of cumbersome operation, complex locking mechanism structure, inability to adapt to the position deviation of the upper body rotating part, etc., and achieve the effect of simple structure requirements and small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the required protection scope is not limited to the description;

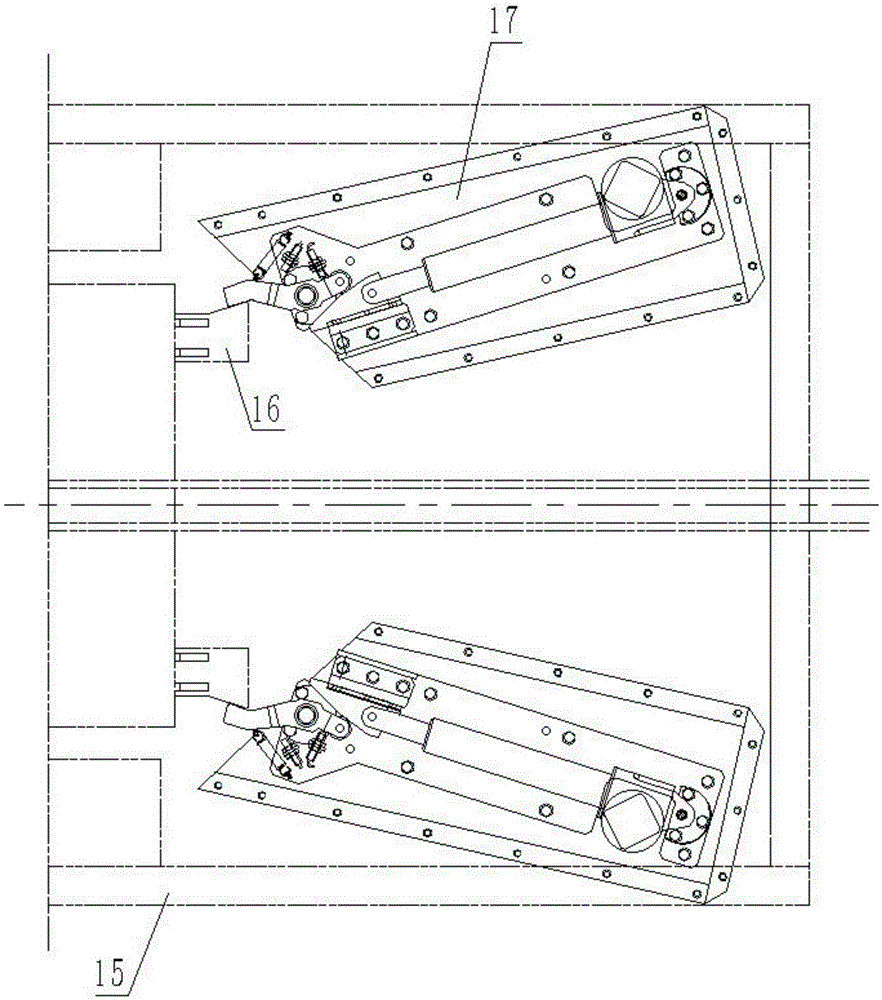

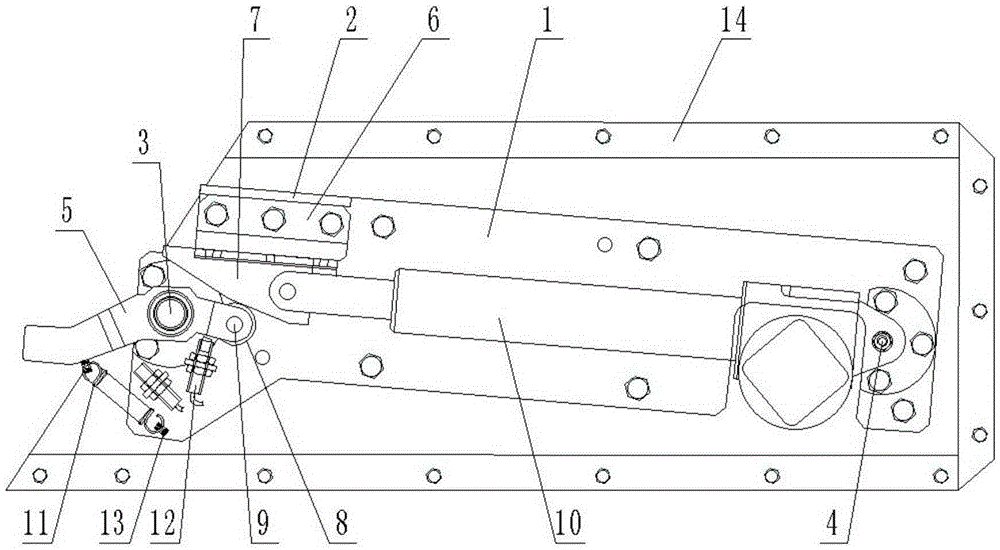

[0020] like Figure 1-2 As shown, the self-adaptive locking device provided by the present invention includes two symmetrically arranged locking mechanisms 17 installed on the support platform 15. The locking mechanism 17 includes a base plate 1, and the left and right ends of the base plate 1 are respectively provided with The rotary shaft A3 and the rotary shaft B4 perpendicular to it, the electric push rod 10 is hinged on the rotary shaft B4, the upper left corner of the bottom plate 1 is provided with a support plate 2, and the pressure plate 6 is installed through the support plate 2, and the electric push rod 10 The end of the telescopic rod is hinged with a slider 7 that matches the pressure plate 6; the rotary shaft A3 is hinged with a locking block 5, and the right end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com