LED panel light back plate mechanism

A lamp backplane and flat panel technology, which is applied in the field of LED lighting, can solve the problems of material loss, increase rework rate, and damage the luminous effect of flat light source, so as to save the cost of lamps and reduce the defective rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

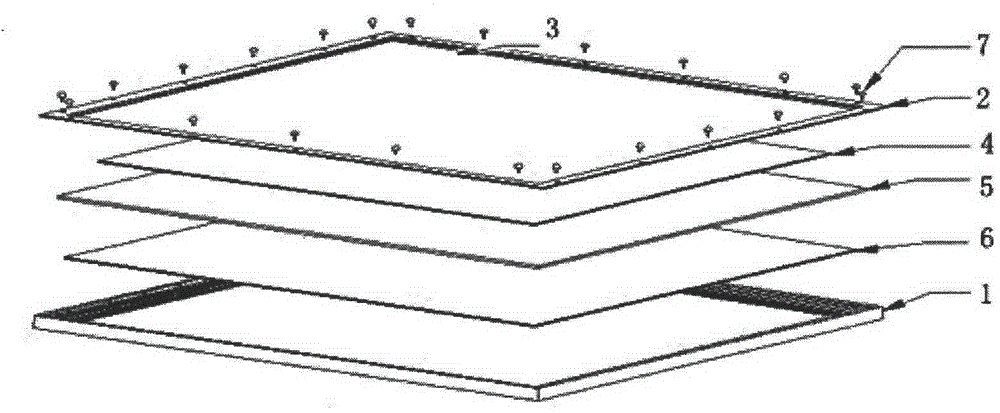

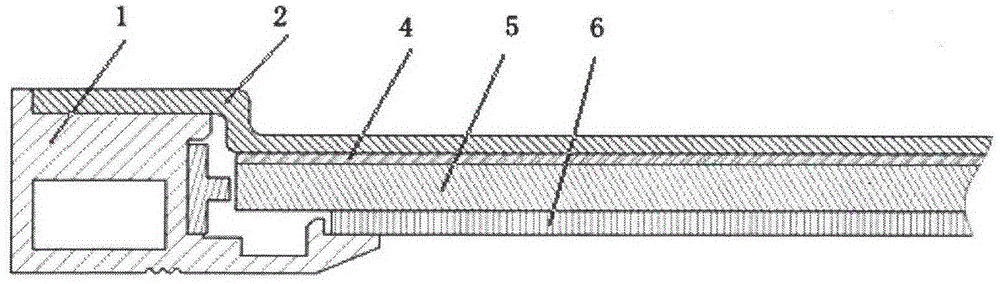

[0012] See figure 1 and figure 2 As shown, a LED panel lamp back panel mechanism has a profile frame 1 and a back panel 2 fixed on the profile frame 1 by screws 7. The back panel 2 is a square frame surface, and its upper surface is stamped into a square groove 3 , the convex surface of the groove 3 is in pressure contact with the surface of the reflective film 4 . A light guide plate 5 is arranged between the profile frames 1 and between the back plates 2 , and the upper surface of the light guide plate 5 is in contact with the reflective film 4 . A diffuser plate 6 is also provided between the profile frames 1 and between the back plates 2 , the upper surface of the diffuser plate 6 is connected to the light guide plate 5 , and the lower surface thereof is connected to the profile frame 1 .

[0013] The specific embodiments described above have further described the purpose, technical solutions and beneficial effects of the present invention in detail. It should be unders...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap