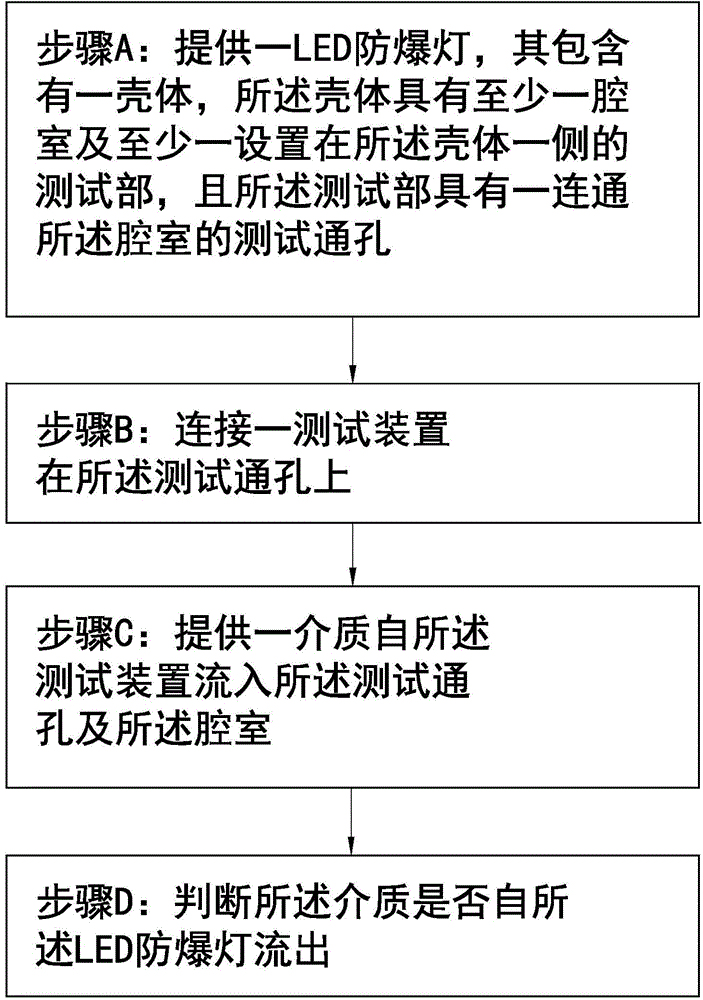

Method for testing LED explosion-proof lamp chamber and structure thereof

A technology of LED explosion-proof lamp and test method, which can be used in gas/waterproof devices, by detecting the appearance of fluid at the leak point, and using liquid/vacuum degree for liquid tightness measurement, etc., which can solve the problem of wasting time and reduce the Effect of time on protection level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

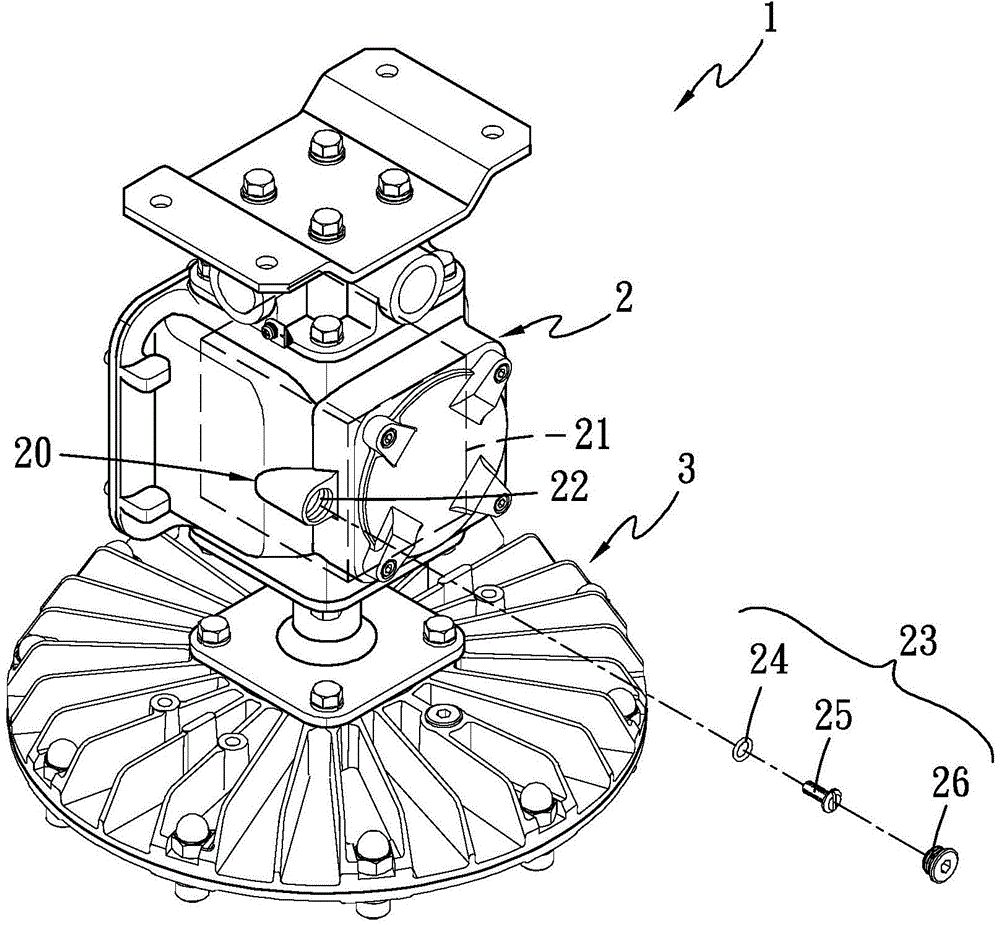

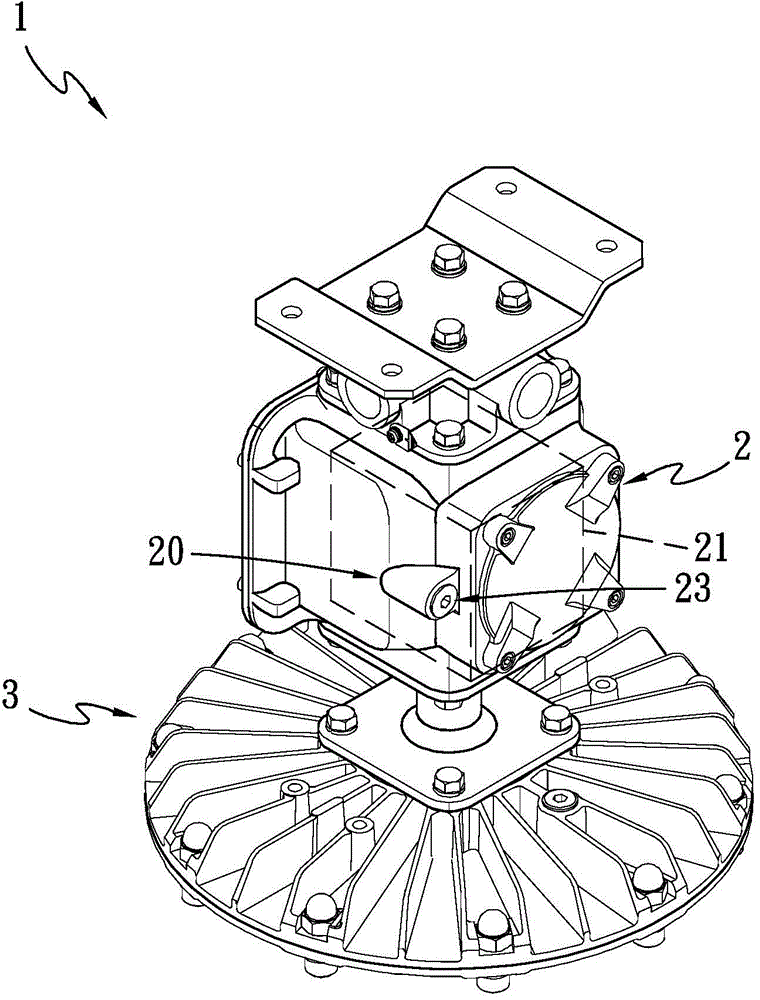

[0039] In conjunction with the accompanying drawings, how the structure of the present invention is combined and used will be explained in detail. It should be easier to understand the purpose, technical content, characteristics and effects of the present invention. Before describing the present invention in detail, it should be noted Yes, in the following description, implementations of different aspects of the same components are represented by the same symbols. Also, for the convenience of explaining the embodiments of the present invention, the directional descriptions mentioned in the following descriptions, such as "upper", "lower", "left", "right", etc., refer to the corresponding elements when referring to the drawings of the present invention. The directional relationships presented in the diagrams do not limit the scope of the claims claimed in the present invention.

[0040] The LED explosion-proof lamp chamber test structure of the present invention can be used in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com