Myriameter water pressure testing device

A hydraulic test and test cylinder technology, applied in the direction of measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of non-reusable, expensive metal sealing ring, non-recoverable plastic deformation of metal sealing ring, etc., to achieve reliable packaging, The effect of shortening the pressing work time and novel structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

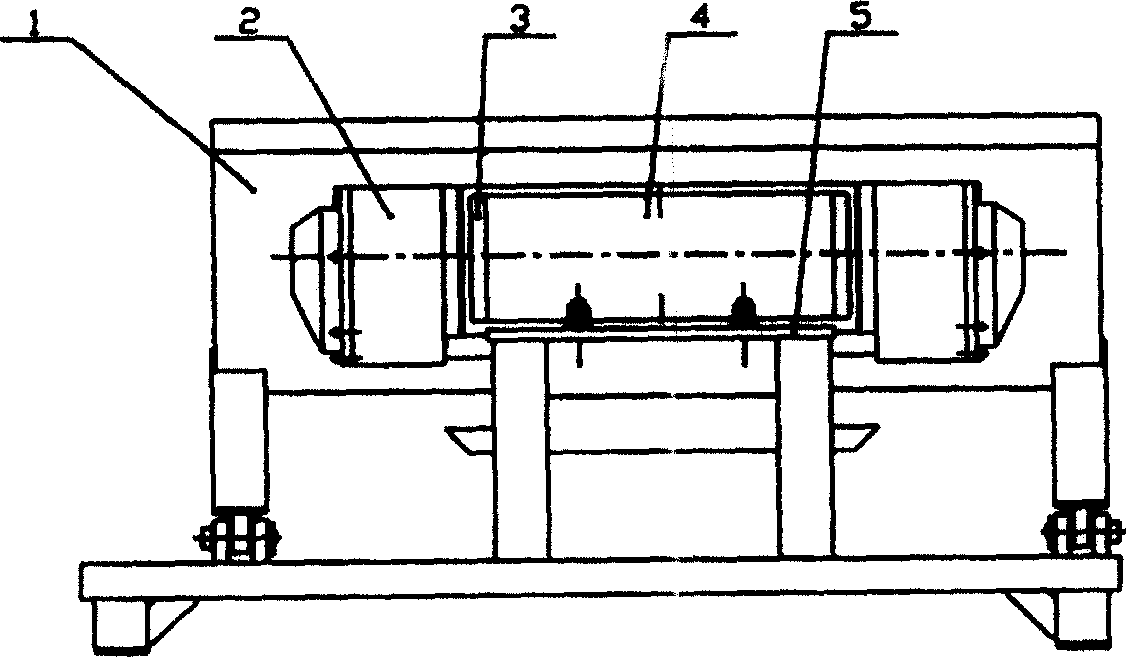

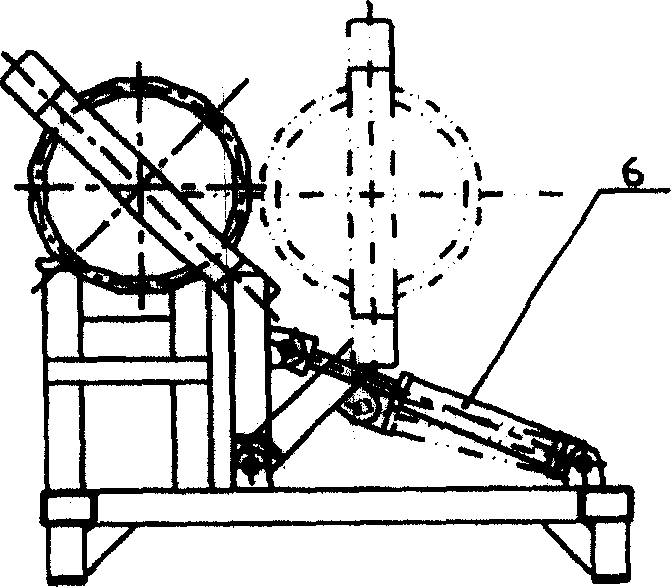

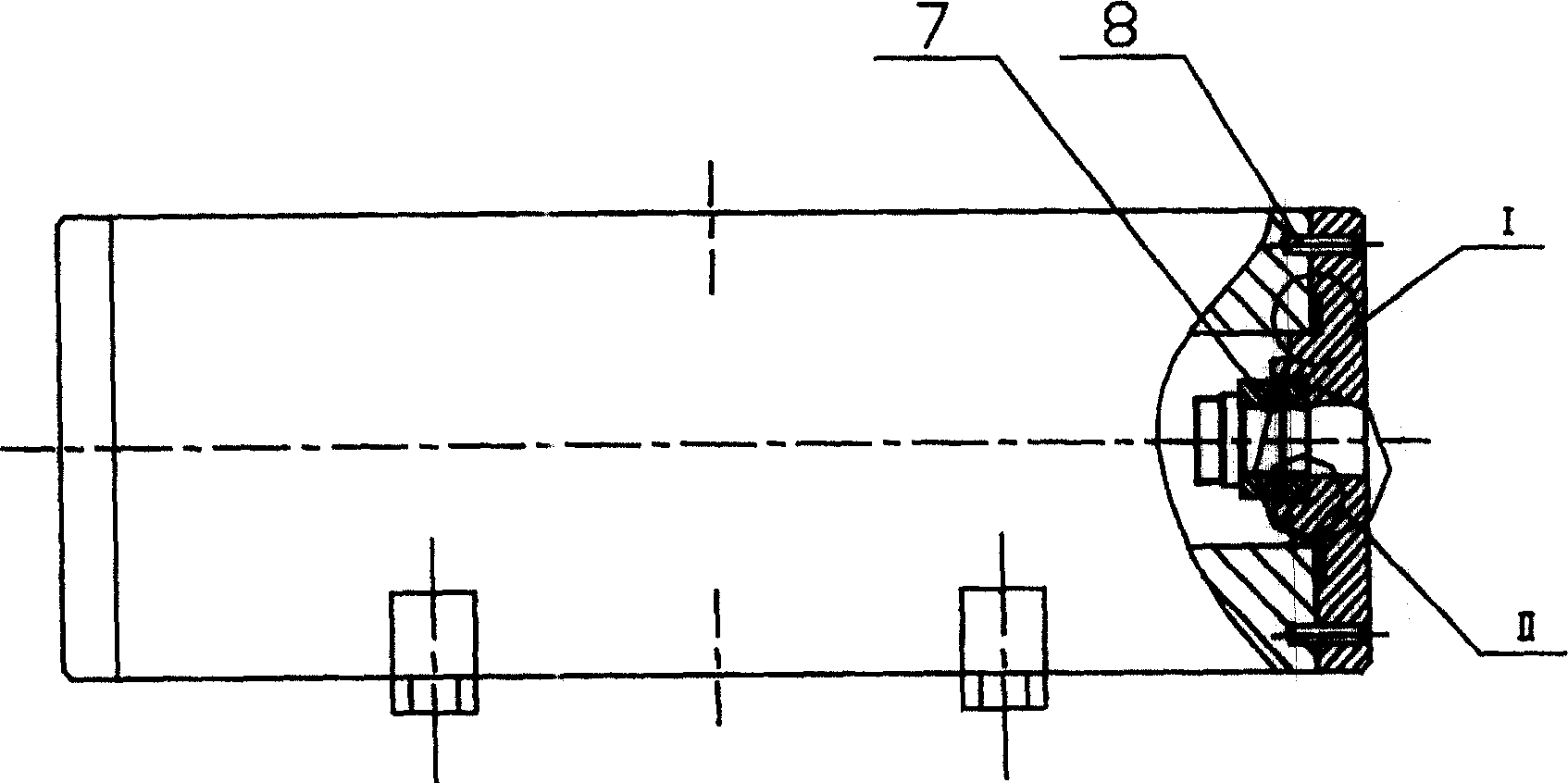

[0016] Such as Figure 1~3 As shown, the 10,000-meter hydraulic test device includes a longitudinal beam 1, a sealed oil cylinder 2, an end cover 3 and a test cylinder 4, wherein: the longitudinal beam 1 is a rotatable Γ-type, and the bottom of the Γ-type is hinged to the bracket 5 , the middle part of the longitudinal beam 1 is connected with the hydraulic drive system (including the driving cylinder, hydraulic station and oil pressure gauge); the sealed oil cylinder 2 is installed with the longitudinal beam 1, and the test cylinder 4 is installed on the support 5, which is located between the two sealed oil cylinders. 2, the test cylinder 4 is equipped with an end cover 3, and the end cover 3 is connected to the hydraulic system (including a pressurized water pump and a hydraulic pressure gauge) through a transition sleeve 7. The end caps 3 are fixed on both ends of the test cylinder 4 by fixing pins 8 .

[0017] Such as Figure 4-2 For the sealing structure between the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com