A structural design method for locking and guiding system of crane compensation device

A technology of structural design and guiding system, applied in the directions of travel mechanism, transportation and packaging, load hanging components, etc., can solve the problems of floating crane movement stability, problems, and the smooth progress of the adverse motion compensation process, so as to improve the compensation Efficiency and reliability, improved reliability, improved adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

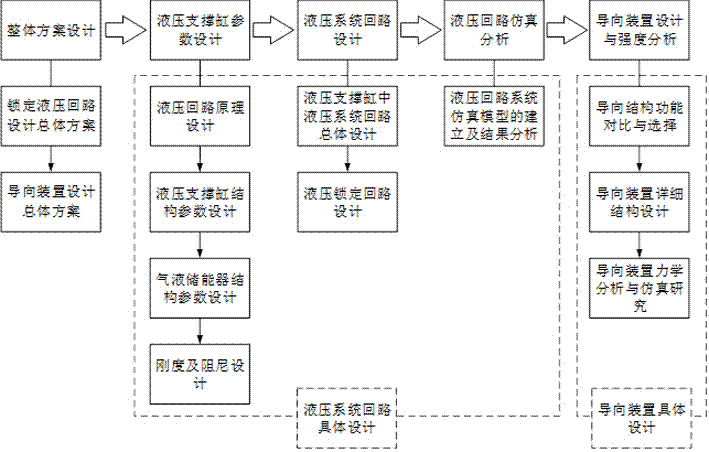

[0033] like figure 1 As shown, a structural design method for the locking and guiding system of the crane heave compensation device includes the following steps:

[0034] S1. Overall scheme design;

[0035] S2. Parameter design of hydraulic support cylinder;

[0036] S3. Hydraulic system circuit design;

[0037] S4. Hydraulic circuit simulation analysis;

[0038] S5. Guide device design and strength analysis.

[0039] In step S1, the overall scheme design includes the following sub-steps:

[0040] S1-1. The overall design scheme of the locking hydraulic circuit: separately design hydraulic cylinders, hydraulic locking circuits with hydraulic control check valves, three-position four-way reversing valves, internal control and internal leakage direct-acting sequence valves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com